A cikin allunan da aka buga masu tsauri, saboda ƙarancin mannewa na rufi a kan bangon rami (fim ɗin rubber mai tsabta da takardar haɗin gwiwa), yana da sauƙi don sa murfin ya rabu da bangon rami lokacin da aka jujjuya yanayin zafi. , Har ila yau yana buƙatar hutu na kusan 20 μm, ta yadda zoben jan karfe na ciki da kuma jan ƙarfe na lantarki suna cikin amintaccen lamba mai lamba uku, wanda ke inganta juriya na thermal shock na rami mai ƙarfe. Capel mai zuwa zai yi magana game da shi dalla-dalla a gare ku. Matakai uku don tsaftace ramin bayan hako katako mai tsauri.

Sanin tsaftacewa a cikin ramin bayan haƙon da'irori masu ƙarfi:

Tun da polyimide ba ya jure wa alkali mai ƙarfi, sauƙi mai ƙarfi alkaline potassium permanganate desmear bai dace da sassauƙan allon bugu ba. Gabaɗaya, dattin hakowa a kan katako mai laushi da wuya ya kamata a tsabtace shi ta hanyar tsabtace plasma, wanda aka raba zuwa matakai uku:

(1) Bayan da rami na kayan aiki ya kai wani mataki na vacuum, high-tsarki nitrogen da high-tsarki oxygen an allura a cikinta daidai gwargwado, babban aikin shine tsaftace bangon ramin, preheat allon da aka buga, da yin kayan polymer. sami wani aiki, wanda ke da fa'ida aiki na gaba. Gabaɗaya, yana da digiri 80 ma'aunin celcius kuma lokacin yana da mintuna 10.

(2) CF4, O2 da Nz suna amsawa tare da guduro azaman iskar gas na asali don cimma manufar ƙazanta da ƙazanta baya, gabaɗaya a ma'aunin Celsius 85 kuma na mintuna 35.

(3) Ana amfani da O2 azaman iskar gas na asali don cire ragowar ko "ƙurar" da aka kafa a lokacin matakai biyu na farko na jiyya; tsaftace bangon rami.

Amma ya kamata a lura da cewa lokacin da ake amfani da plasma don cire datti mai hakowa a cikin ramukan da aka buga na Multi-Layer m da m-m-m bugu allon, da etching gudun daban-daban kayan ne daban-daban, da kuma oda daga babba zuwa karami ne: acrylic fim. , epoxy guduro, polyimide, fiberglass da jan karfe. Ana iya ganin kawunan filayen gilashin da ke fitowa da zoben jan karfe a fili a bangon ramin daga na'urar hangen nesa.

Don tabbatar da cewa maganin plating na tagulla mara amfani zai iya tuntuɓar bangon ramin, don kada murfin jan ƙarfe ya haifar da ɓarna da ɓarna, ragowar halayen plasma, fiber gilashin da ke fitowa da fim ɗin polyimide akan bangon rami dole ne su kasance. cire. Hanyar jiyya ta haɗa da sinadarai na inji da hanyoyin injuna ko haɗin biyun. Hanyar sinadarai ita ce a jiƙa allon da aka buga tare da maganin ammonium hydrogen fluoride, sannan a yi amfani da ion surfactant (KOH bayani) don daidaita cajin bangon ramin.

Hanyoyin injina sun haɗa da ɓarkewar yashi mai tsananin ƙarfi da kuma yawan wanke ruwa. Haɗuwa da hanyoyin sinadarai da injiniyoyi suna da mafi kyawun sakamako. Rahoton metallographic ya nuna cewa yanayin bangon ramin da aka karafa bayan lalatawar jini yana da gamsarwa.

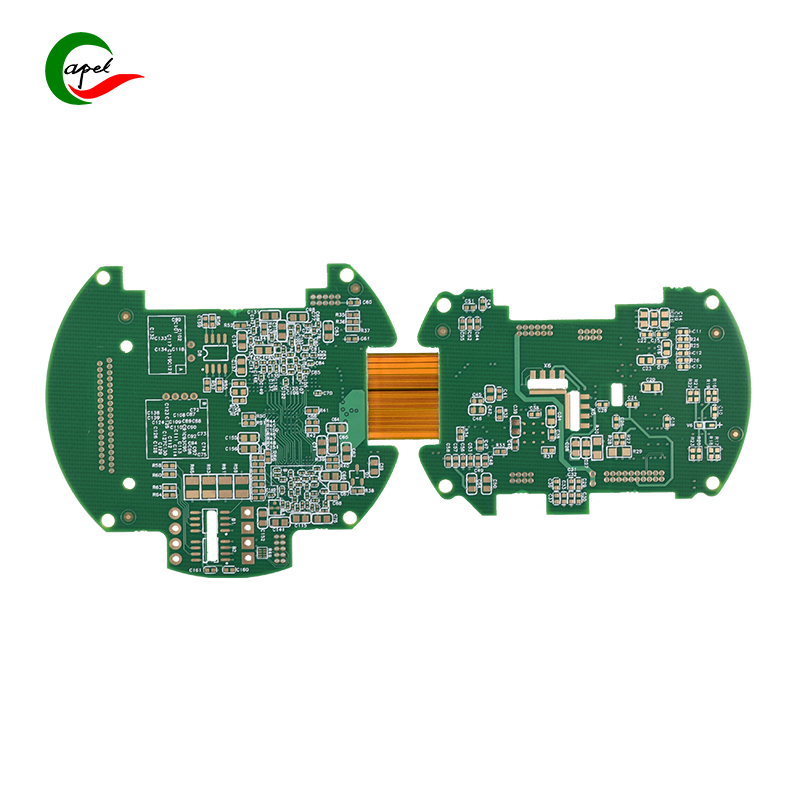

Abubuwan da ke sama sune matakai uku na tsaftace cikin ramin bayan hakowa na allunan da aka buga a hankali da Capel ya tsara a hankali. Capel ya mayar da hankali kan madaidaicin madaurin da'ira mai sassauƙa, katako mai laushi, katako mai wuya da taron SMT na tsawon shekaru 15, kuma ya tara tarin ilimin fasaha a cikin masana'antar hukumar kewaye. Ina fatan wannan rabawa zai taimaka wa kowa. Idan kuna da ƙarin wasu tambayoyin hukumar da'ira, da fatan za a tuntuɓi ƙungiyar ƙwararrun masana'antar kayan shafa na Capel kai tsaye don ba da tallafin fasaha na ƙwararrun don aikinku.

Lokacin aikawa: Agusta-21-2023

Baya