Yayin da buƙatar sassauƙa da ƙaƙƙarfan hanyoyin lantarki ke ci gaba da ƙaruwa, PCBs masu sassaucin ra'ayi sun zama sanannen zaɓi a ƙirar PCB da masana'anta.Waɗannan allunan sun haɗu da fa'idodin PCB masu tsauri da sassauƙa don samar da ingantacciyar sassauci ba tare da sadaukar da dorewa da aiki ba.Don ƙirƙira amintattun kuma ingantattun PCBs masu sassaucin ra'ayi, cikakkiyar fahimtar daidaitawar tari yana da mahimmanci.Tsarin tarawa yana ƙayyadaddun tsari da tsarin tsarin PCB, yana shafar aikin sa kai tsaye da iyawar sa.Wannan cikakkiyar jagorar za ta zurfafa cikin rikitattun abubuwan tattarawar PCB masu tsauri, samar da fa'ida mai mahimmanci don taimakawa masu zanen kaya su yanke shawara mai zurfi yayin aikin ƙira. Zai rufe fannoni daban-daban da suka haɗa da zaɓin kayan abu, sanya Layer, la'akari da amincin sigina, sarrafa impedance, da ƙarancin masana'antu. Ta hanyar fahimtar rikitattun abubuwan tattarawar PCB masu ƙarfi, masu ƙira za su iya tabbatar da mutunci da amincin ƙirar su.Za su inganta amincin sigina, rage tsangwama na lantarki (EMI) da sauƙaƙe ayyukan masana'antu masu inganci.Ko kun kasance sababbi ga ƙirar PCB mai tsauri ko neman haɓaka ilimin ku, wannan jagorar za ta zama hanya mai mahimmanci, tana ba ku damar kewaya abubuwan da ke tattare da abubuwan daidaitawa da ƙirƙira ingantattun hanyoyin PCB masu sassauci don kewayon samfuran.

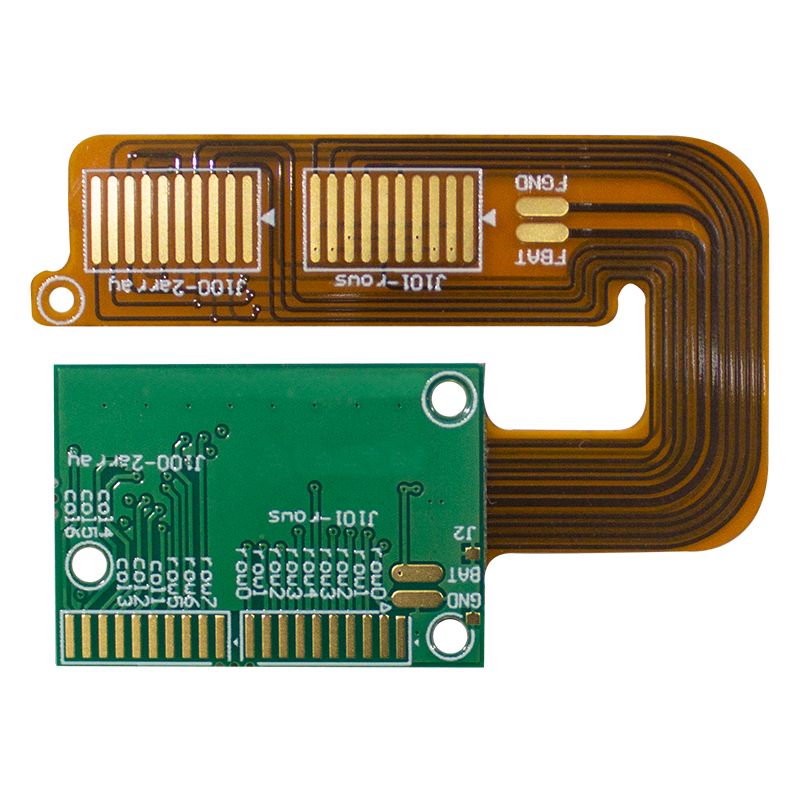

1.What is a rigid-flex board?

Rigid-flex board, wanda kuma aka sani da rigid-flex printed Circuit Board (PCB), PCB ne wanda ke haɗa madaidaitan madaukai masu sassauƙa akan allo ɗaya.Yana haɗa fa'idodin PCBs masu ƙarfi da sassauƙa don haɓaka sassaucin ƙira da dorewa.A cikin allo mai sassauƙa, tsayayyen ɓangaren an yi shi da kayan PCB na gargajiya (kamar FR4), yayin da sassauƙan ɓangaren an yi shi da kayan PCB masu sassauƙa (kamar polyimide).Waɗannan sassan suna haɗe-haɗe ta hanyar plated ta ramuka ko masu haɗawa don samar da allon haɗaɗɗiya guda ɗaya.Sassan sassa masu ƙarfi suna ba da tallafi da kwanciyar hankali ga abubuwan haɗin gwiwa, masu haɗawa, da sauran abubuwan injina, kama da daidaitaccen PCB mai tsauri.Sashi mai sassauƙa, a gefe guda, yana ba da damar allon kewayawa don lanƙwasa da lanƙwasa, yana ba shi damar shiga cikin na'urorin lantarki waɗanda ke da iyakacin sarari ko siffofi marasa tsari.Alƙalai masu sassaucin ra'ayi suna ba da fa'idodi da yawa akan PCBs masu tsauri ko sassauƙa na gargajiya.Suna rage buƙatar masu haɗawa da igiyoyi, adana sararin samaniya, rage girman lokacin taro, da kuma ƙara yawan aminci ta hanyar kawar da yiwuwar gazawar.Bugu da ƙari, allunan masu sassauƙa da sauƙi suna sauƙaƙe tsarin ƙira ta hanyar sauƙaƙe haɗin kai tsakanin sassa masu ƙarfi da sassauƙa, rage rikiɗar hanyar tuƙi da haɓaka amincin sigina.Ana amfani da allunan masu sassauƙa sosai a aikace-aikace inda sarari ya iyakance ko allon yana buƙatar dacewa da takamaiman siffa ko bayanin martaba.Ana samun su sau da yawa a cikin sararin samaniya, na'urorin likitanci, na'urorin lantarki na mota da na'urorin lantarki masu ɗaukuwa inda girman, nauyi da aminci sune mahimman abubuwan.Zanewa da kera kwamitoci masu tsattsauran ra'ayi na buƙatar ilimi na musamman da ƙwarewa saboda haɗuwa da kayan aiki masu ƙarfi da sassauƙa da haɗin kai.Don haka, yana da mahimmanci a yi aiki tare da gogaggen masana'anta na PCB wanda ke da ikon sarrafa sarƙaƙƙiya na masana'antar katako mai sassauƙa.

2.Why ne m flex pcb stacking sanyi muhimmanci?

Ingantacciyar Injiniya:

An ƙera PCBs masu tsauri don samar da sassauci da aminci.Tsarin tarawa yana ƙayyadaddun tsari na yadudduka masu tsauri da sassauƙa, tabbatar da cewa hukumar zata iya jure lankwasawa, karkatarwa da sauran matsalolin injina ba tare da lalata amincin tsarin sa ba.Daidaita layin da ya dace yana da mahimmanci don hana gajiyar PCB, yawan damuwa, da gazawa akan lokaci.

Inganta sararin samaniya:

Ana amfani da alluna masu tsattsauran ra'ayi a cikin ƙaƙƙarfan na'urorin lantarki masu iyakacin sarari.Tsare-tsare masu tarin yawa suna ba masu ƙira damar yin amfani da sararin samaniya da kyau ta hanyar tsara yadudduka da abubuwan haɗin kai ta hanyar da za ta ƙara girman amfani da sararin 3D.Wannan yana ba da damar shigar da PCBs a cikin matsuguni masu ɗorewa, ƙananan na'urori da abubuwa masu rikitarwa.Mutuncin Sigina:

Mutuncin siginar PCB mai sassauci yana da mahimmanci ga aikin da ya dace.Tsare-tsaren tari yana taka muhimmiyar rawa wajen inganta amincin sigina ta hanyar la'akari da abubuwa kamar su rashin ƙarfi mai sarrafawa, jigilar layin watsawa, da rage yawan magana.Madaidaicin shimfidar wuri mai ma'ana zai iya tabbatar da ingantacciyar hanyar sarrafa sigina masu sauri, rage rage siginar, da tabbatar da ingantaccen watsa bayanai.

Gudanar da thermal:

Na'urorin lantarki suna haifar da zafi, kuma ingantaccen sarrafa zafin jiki yana da mahimmanci don hana zafi da yuwuwar lalacewa ga abubuwan da aka gyara.Tsare-tsare na PCBs mai tsauri yana ba da damar tsara dabarun jeri ta hanyar thermal, yadudduka na tagulla, da magudanar zafi don ingantaccen watsawar zafi.Ta hanyar la'akari da al'amurran da suka shafi thermal yayin tsarin ƙira, masu zanen kaya na iya tabbatar da tsawon rayuwar PCB da aminci.

La'akari da masana'antu:

Tsari tari yana shafar tsarin masana'anta na PCB mai tsauri.Yana ƙayyadad da tsari wanda aka haɗa nau'i-nau'i tare, daidaitawa da rajista na sassauƙa da maɗaukaki, da kuma sanya kayan aiki.Ta hanyar a hankali zabar gyare-gyaren gyare-gyare, masu zanen kaya na iya daidaita tsarin masana'antu, rage farashin samarwa, da kuma rage haɗarin kurakuran masana'antu.

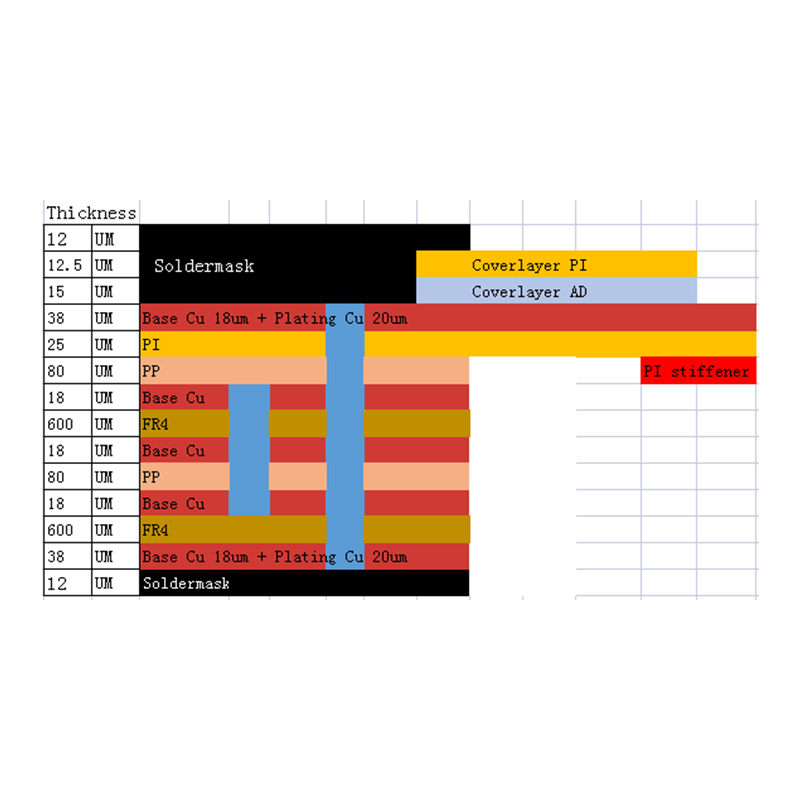

3.Key abubuwan da aka gyara na m-m PCB stackup

Lokacin zayyana madaidaicin tari na PCB, akwai abubuwa da yawa da za a yi la'akari da su.Waɗannan ɓangarorin suna taka muhimmiyar rawa wajen samar da ingantaccen tsarin tallafi, haɗin lantarki, da sassauci don ƙirar PCB gabaɗaya.Abubuwan da ke biyowa sune mahimman abubuwan haɗin PCB mai tsauri:

Layer mai tsauri:

Tsayayyen Layer yawanci ana yin shi daga ƙaƙƙarfan kayan tushe kamar FR-4 ko makamancinsa.Wannan Layer yana ba da ƙarfin injiniya da kwanciyar hankali ga PCB.Hakanan yana ba da izinin shigar da na'urorin hawan saman (SMD) da abubuwan haɗin ramuka.Ƙaƙƙarfan ƙaƙƙarfan ƙaƙƙarfan ƙaƙƙarfan tushe yana ba da tushe mai ƙarfi don sassauƙa mai sassauƙa kuma yana tabbatar da daidaitaccen daidaitawa da tsayin daka na duka PCB.

Layer mai sassauƙa:

Maɗaukaki mai sassauƙa ya ƙunshi kayan tushe mai sassauƙa kamar polyimide ko makamancin haka.Wannan Layer yana ba PCB damar lanƙwasa, ninke, da sassauƙa.Layin sassauƙa shine inda galibin hanyoyin sadarwa da haɗin wutar lantarki suke.Yana ba da sassaucin da ake buƙata don aikace-aikacen da ke buƙatar PCB don lanƙwasa ko daidaita zuwa siffofi ko sarari daban-daban.Ana buƙatar yin la'akari da sassaucin wannan Layer a hankali don tabbatar da ya dace da bukatun aikace-aikacen.

Layer na m:

Ƙaƙƙarfan mannewa wani ɗan ƙaramin abu ne na bakin ciki wanda aka yi amfani da shi a tsakanin tsayayyen Layer da mai sassauƙa.Babban manufarsa ita ce haɗa madaidaitan yadudduka masu sassauƙa tare, samar da daidaiton tsari ga laminate.Yana tabbatar da cewa yadudduka sun ci gaba da kasancewa da haɗin kai da juna har ma yayin lanƙwasa ko motsi.Har ila yau, Layer na manne yana aiki azaman dielectric abu, yana samar da rufi tsakanin yadudduka.Zaɓin kayan ɗamara yana da mahimmanci yayin da yake buƙatar samun kyawawan abubuwan haɗin kai, ƙarfin ƙarfin dielectric, da dacewa tare da kayan tushe.

Ƙarfafawa da rufewa:

Ƙarfafawa da rufaffiyar ƙarin yadudduka ne galibi ana ƙara su zuwa tarin PCB don haɓaka ƙarfin injinsa, kariya, da amincinsa.Ƙarfafawa na iya haɗawa da kayan kamar FR-4 ko zanen gadon da ba su da tushe na polyimide waɗanda aka lakafta zuwa takamaiman wurare na yadudduka masu ƙarfi ko sassauƙa don samar da ƙarin ƙarfi da tallafi.Ana lulluɓe saman PCB tare da sutura irin su abin rufe fuska da kayan kariya don kare su daga abubuwan muhalli kamar danshi, ƙura, da damuwa na inji.

Waɗannan mahimman abubuwan haɗin gwiwar suna aiki tare don ƙirƙira a tsanake ƙera faifan PCB mai tsauri wanda ya dace da buƙatun aikace-aikacen.Daidaitaccen tsari da sassaucin ra'ayi da aka bayar ta madaidaitan yadudduka masu sassauƙa, da kuma manne-dare, tabbatar da cewa PCB na iya jure jurewar lanƙwasa ko motsi ba tare da lalata amincin kewaye ba.Bugu da ƙari, yin amfani da ƙarfafawa da sutura yana haɓaka cikakken aminci da kariya na PCB.Ta hanyar zaɓar da zayyana waɗannan abubuwan a hankali, injiniyoyi za su iya ƙirƙirar fakitin PCB masu ƙarfi da aminci.

4.Rigid-flex PCB stackup sanyi nau'in

Lokacin zayyana rijiyoyin PCB masu ƙarfi, ana iya amfani da nau'ikan sanyi daban-daban dangane da takamaiman buƙatun aikace-aikacen.Ƙididdigar tari yana ƙayyade adadin adadin da aka haɗa a cikin ƙira da kuma tsari na tsauri da sassauƙa.Wadannan nau'o'in gama-gari guda uku ne na daidaitawar PCB mai tsauri:

1 Layer na m da taushi lamination:

A cikin wannan saitin, PCB ya ƙunshi nau'i ɗaya na abu mai tsauri da Layer guda ɗaya na kayan sassauƙa.Tsayayyen Layer yana ba da kwanciyar hankali da goyan baya da ake buƙata, yayin da sassauƙan Layer damar PCB ta lanƙwasa.Wannan saitin ya dace da aikace-aikacen da ke buƙatar ƙayyadadden sassauci da ƙira mai sauƙi.

2 yadudduka na m da taushi superposition:

A cikin wannan saitin, PCB ya ƙunshi yadudduka biyu - maɗauri mai ƙarfi da mai sassauƙa.An yi sandwiched wani m Layer tsakanin sassa biyu masu sassauƙa, ƙirƙirar tsarin "littafi".Wannan saitin yana ba da sassauci mafi girma kuma yana ba da damar ƙarin ƙira mai rikitarwa ta amfani da abubuwan haɗin gwiwa a bangarorin biyu na PCB.Yana ba da mafi kyawun sassauci a cikin lanƙwasa da lanƙwasa fiye da saitin Layer Layer.

Multi-Layer m da taushi superposition:

A cikin wannan saitin, PCB ya ƙunshi nau'i-nau'i masu yawa - haɗuwa da yadudduka masu tsayi da sassauƙa.Yaduddukan an jera su a saman juna, suna musaya tsakanin yadudduka masu ƙarfi da sassauƙa.Wannan saitin yana ba da mafi girman matakin sassauci kuma yana ba da izinin ƙira mafi rikitarwa ta amfani da abubuwa masu yawa da da'irori.Ya dace da aikace-aikacen da ke buƙatar babban sassauci da ƙirar ƙira.

Zaɓin daidaitawar tari mai tsattsauran ra'ayi ya dogara da dalilai kamar matakin sassaucin da ake buƙata, ƙayyadaddun ƙirar da'irar, da iyakokin sararin samaniya.Injiniyoyin suna buƙatar kimanta buƙatun aikace-aikacen a hankali da iyakancewa don tantance mafi dacewa daidaitaccen tsarin tarawa.

Bugu da ƙari ga ginin laminate mai tsauri, wasu dalilai kamar zaɓin kayan abu, kauri na kowane Layer, da ta hanyar da ƙirar haɗin kai kuma suna taka muhimmiyar rawa wajen tantance aikin gabaɗaya da amincin PCBs masu sassaucin ra'ayi.Yana da mahimmanci a yi aiki tare tare da masana'anta na PCB da ƙwararrun ƙira don tabbatar da cewa ƙayyadaddun ƙayyadaddun ƙayyadaddun bayanai sun cika takamaiman buƙatu da ƙa'idodin aikace-aikacen.

Ta hanyar zabar daidaitaccen tsari mai tsauri-sauƙaƙƙiya da haɓaka sauran sigogin ƙira, injiniyoyi na iya aiwatar da abin dogaro, manyan ayyuka na rigid-flex PCBs waɗanda ke biyan buƙatun musamman na aikace-aikacen su.

5.Abubuwan da za a yi la'akari da lokacin da zabar Kanfigareshan PCB mai ƙarfi-Flex Stacking

Lokacin zabar daidaitaccen tsari na PCB mai sassauƙa, akwai abubuwa da yawa da za a yi la'akari da su don tabbatar da ingantaccen aiki da aminci.Ga muhimman abubuwa guda biyar da ya kamata ku kiyaye:

Mutuncin Sigina:

Zaɓin saitin tarawa na iya tasiri sosai ga amincin siginar PCB.Alamun sigina akan yadudduka masu sassauƙa na iya samun halaye daban-daban na impedance idan aka kwatanta da m yadudduka.Yana da mahimmanci don zaɓar saitin tarawa wanda ke rage asarar sigina, magana ta giciye, da rashin daidaituwar impedance.Ya kamata a yi amfani da ingantattun dabarun sarrafa ƙwanƙwasa don kiyaye amincin sigina a cikin PCB.

Bukatun sassauci:

Matsayin sassaucin da ake buƙata na PCB muhimmin abin la'akari ne.Aikace-aikace daban-daban na iya samun buƙatun lanƙwasawa daban-daban.Ya kamata a zaɓi saitin tarawa don ɗaukar sassaucin da ake buƙata yayin tabbatar da cewa PCB ya cika duk buƙatun aikin injiniya da lantarki.Ya kamata a ƙayyade lamba da tsari na yadudduka masu sassauƙa a hankali bisa takamaiman buƙatun aikace-aikacen.

Matsalolin sararin samaniya:

Wurin da ke akwai a cikin samfur ko na'ura na iya tasiri sosai ga zaɓin daidaitawar tari.Ƙirƙirar ƙira tare da iyakanceccen sarari na PCB na iya buƙatar saiti mai ƙarfi-launi mai yawa don haɓaka amfani da sarari.A gefe guda, ƙira mafi girma suna ba da damar ƙarin sassauci yayin zabar jeri-up.Haɓaka tarawa don dacewa da sararin samaniya ba tare da lalata aiki ko aminci yana da mahimmanci ba.

Gudanar da thermal:

Ingantacciyar kula da zafi yana da mahimmanci don hana haɓakar zafi, wanda zai iya shafar aiki da amincin da'irori da abubuwan haɗin gwiwa.Zaɓin saitin tarawa ya kamata yayi la'akari da zubar da zafi.Alal misali, idan PCB yana haifar da zafi mai yawa, yana iya buƙatar tsarawa wanda ke taimakawa wajen watsar da zafi, kamar hada da muryoyin ƙarfe ko amfani da thermal vias.Hakanan ya kamata a sanya abubuwan dumama cikin dabarar a cikin tari don watsar da zafi da kyau.

La'akari da Kerawa da Taro:

Tsarin tarawa da aka zaɓa ya zama mai sauƙin ƙirƙira da haɗawa.Ya kamata a yi la'akari da abubuwa kamar sauƙi na masana'antu, dacewa tare da tsarin masana'antu da fasahar taro, da kuma samun kayan aiki masu dacewa.Misali, wasu jeri-rufe na iya buƙatar fasahohin masana'antu na musamman ko ƙila su sami iyaka a cikin kayan da za a iya amfani da su.Yin aiki tare da masana'anta na PCB a farkon tsarin ƙira yana da mahimmanci don tabbatar da cewa za'a iya samar da tsarin da aka zaɓa kuma a haɗa shi da kyau.

Ta hanyar kimanta waɗannan abubuwa guda biyar a hankali, injiniyoyi za su iya yanke shawara game da zaɓin daidaitawar PCB mai tsauri.An ba da shawarar sosai don yin aiki tare da ƙwararren masana'antu da taro don tabbatar da cewa tsarin da aka zaɓa ya dace da duk bukatun ƙira kuma ya dace da tsarin samarwa.Keɓance tari don magance daidaiton siginar, sassauci, iyakokin sararin samaniya, sarrafa zafi da la'akari da masana'anta zai haifar da ingantaccen ingantaccen ingantaccen bayani na PCB.

6.Design la'akari don m-m PCB tari-up

Lokacin zayyana madaidaicin tari na PCB, akwai abubuwa masu mahimmanci da yawa da za a yi la'akari da su don tabbatar da ingantaccen aiki da aminci.Anan akwai mahimman abubuwan ƙira guda biyar:

Rarraba Layer da Alama:

Rarraba Layer a cikin tari yana da mahimmanci don cimma daidaito da daidaito a cikin ƙira.Wannan yana taimakawa hana rikice-rikice ko rikice-rikice yayin aikin lankwasawa.An bada shawara don samun adadin yadudduka a kowane gefen sassa na sassa da kuma sanya flayer Layer a tsakiyar tari.Wannan yana tabbatar da daidaitaccen rarraba damuwa kuma yana rage haɗarin gazawa.

Kebul da Tsarin Layi:

Ya kamata a yi la'akari da shimfidar igiyoyi da alamu akan PCB a hankali.Yakamata a shirya hanyar zirga-zirgar igiyoyi da alamu don rage yawan damuwa da hana lalacewa yayin lankwasawa.Ana ba da shawarar a bi hanyoyin igiyoyi masu sassauƙa da saƙon nesa daga wuraren da ke da matsanancin lanƙwasawa, kamar kusa da wuraren lanƙwasa.Bugu da ƙari, yin amfani da sasanninta masu zagaye maimakon kusurwoyi masu kaifi na iya rage damuwa da kuma inganta sassaucin PCB.

Jiragen Kasa Da Wutar Lantarki:

Rarraba jirgin ƙasa da wutar lantarki suna da matukar mahimmanci don kiyaye daidaitaccen siginar siginar da rarraba wutar lantarki.Ana ba da shawarar rarraba ƙasa da jiragen sama masu ƙarfi don samar da daidaitattun rarraba wutar lantarki a cikin PCB.Waɗannan yadudduka kuma suna aiki azaman garkuwar tsoma baki (EMI).Matsayin da ya dace na ta hanyar ƙasa da ɗinkin ta hanyar yana da mahimmanci don rage ƙarancin ƙasa da haɓaka aikin EMI.

Binciken amincin sigina:

Mutuncin sigina yana da mahimmanci ga aikin yau da kullun na PCB.Ya kamata a tsara alamun sigina a hankali don rage katsewa, magana, da tunanin sigina.Masu zanen PCB yakamata su yi amfani da kayan aikin software don yin nazarin ƙimar sigina don haɓaka faɗin alama da tazara, kula da rashin ƙarfi, da tabbatar da amincin sigina a duk faɗin PCB mai sassauƙa.

Wurare masu sassauƙa da lanƙwasa:

Sassauka masu sassauƙa da tsattsauran ra'ayi na PCB suna da buƙatu daban-daban dangane da sassauƙa da lankwasawa.Wajibi ne a ayyana da zayyana takamaiman wurare don sassauƙa da sassauƙa.Yankin sassauƙa ya kamata ya zama mai sassauƙa don ɗaukar radiyon lanƙwasa da ake buƙata ba tare da annashuwa ba ko abubuwan haɗin gwiwa.Ana iya amfani da dabarun ƙarfafawa irin su haƙarƙari ko suturar polymer don ƙara ƙarfin injiniya da amincin wurare masu sassauƙa.

Ta yin la'akari da waɗannan abubuwan ƙira, injiniyoyi za su iya haɓaka ingantattun ingantattun faifan PCB.Yana da mahimmanci a yi aiki tare da masana'antun PCB don fahimtar iyawarsu, zaɓuɓɓukan kayan aiki, da iyakokin masana'antu.Bugu da ƙari, shigar da ƙungiyar masana'anta a farkon tsarin ƙira na iya taimakawa warware duk wani matsala na ƙira da tabbatar da sauyi mai sauƙi daga ƙira zuwa samarwa.Ta hanyar ba da hankali ga rarraba Layer, kewayawa da sanya alama, ƙasa da jirage masu ƙarfi, amincin sigina da sassauƙan sassauƙa, masu zanen kaya na iya ƙirƙirar abin dogaro da cikakken aiki na PCBs masu ƙarfi.

7.Layer zane fasaha don m m pcb

Lokacin zayyana alluna masu sassauƙa, fasahohin ƙirar Layer suna taka muhimmiyar rawa wajen tabbatar da ingantaccen aiki da aminci.Anan akwai dabarun ƙira maɓalli guda huɗu:

Lamination na jere:

Lamination na jerin gwano fasaha ce da aka saba amfani da ita a cikin masana'anta mai sassauƙa.A cikin wannan hanyar, ana kera yadudduka daban-daban masu ƙarfi da sassauƙa daban sannan a lika su tare.Yawancin yadudduka ana yin su ta amfani da FR4 ko makamantansu, yayin da ake yin yadudduka masu sassauƙa ta amfani da polyimide ko makamancin sassauƙa.Lamination na jeri yana ba da sassauci mafi girma a zaɓin Layer da kauri, yana ba da damar iko mafi girma akan kayan lantarki da na inji na PCB.Lamination na Hanya Biyu:

A cikin lamination na samun dama biyu, ana hakowa ta hanyar a cikin madaidaitan yadudduka masu sassauƙa don ba da damar shiga bangarorin biyu na PCB.Wannan fasaha yana ba da sassauci mafi girma a cikin jeri na sassa da kuma hanyar ganowa.Hakanan yana goyan bayan amfani da makafi da binne ta hanyar, wanda ke taimakawa rage ƙidayar Layer da inganta amincin sigina.Lamination na tashar tashoshi biyu yana da amfani musamman yayin zayyana hadaddun PCBs masu tsauri tare da yadudduka da yawa da ƙarancin sarari.

Adhesive na axis Z-axis:

Ana amfani da adhesive conductive Z-axis don kafa haɗin wutar lantarki tsakanin madaidaicin Layer da mai sassauƙa a cikin allo mai sassauƙa.Ana amfani da shi a tsakanin madaidaicin maɗaukaki a kan madauri mai sassauƙa da madaidaicin madaidaicin a kan m Layer.Adhesive yana ƙunshe da barbashi masu ɗaukar nauyi waɗanda ke samar da hanyoyin gudanarwa lokacin da aka matsa tsakanin yadudduka yayin lamination.Adhesive conductive Z-axis yana ba da ingantaccen haɗin lantarki yayin da yake riƙe da sassaucin PCB da amincin injina.

Tsare-tsare na haɗe-haɗe:

A cikin ƙayyadaddun tsarin tarawa, ana amfani da haɗe-haɗe na yadudduka masu ƙarfi da sassauƙa don ƙirƙirar tari na musamman.Wannan yana bawa masu zanen kaya damar haɓaka shimfidar PCB bisa ƙayyadaddun buƙatun ƙira.Misali, ana iya amfani da yadudduka masu tsauri don hawa abubuwan haɗin gwiwa da kuma samar da ƙarfin injina, yayin da za a iya amfani da yadudduka masu sassauƙa don daidaita sigina a wuraren da ake buƙatar sassauci.Haɗaɗɗen jeri-nau'i suna ba masu ƙira tare da babban matsayi na sassauƙa da keɓancewa don rikitattun ƙirar PCB masu tsauri.

Ta hanyar yin amfani da waɗannan fasahohin ƙira na Layer, masu zanen kaya na iya ƙirƙirar PCB masu ƙarfi da ƙarfi waɗanda suke da ƙarfi da aiki.Koyaya, yana da mahimmanci a yi aiki tare da masana'anta na PCB don tabbatar da cewa fasahar da aka zaɓa ta dace da ƙarfin masana'anta.Sadarwa tsakanin ƙungiyoyin ƙira da masana'anta yana da mahimmanci don warware duk wani matsala mai yuwuwa da tabbatar da sauyi mai sauƙi daga ƙira zuwa samarwa.Tare da ingantattun dabarun ƙira na Layer, masu zanen kaya za su iya cimma aikin wutar lantarki da ake buƙata, sassauƙan injina da aminci a cikin PCBs masu ƙarfi.

8.Rigid-m PCB lamination fasahar ci gaba

Ci gaba a fasahar lamination na PCB masu tsauri sun sami ci gaba a fagage daban-daban.Ga fagage guda huɗu na fitattun ci gaba:

Ƙirƙirar Abu:

Ci gaba a kimiyyar kayan aiki sun sauƙaƙe haɓaka sabbin kayan ƙasa waɗanda aka ƙera musamman don alluna masu ƙarfi.Waɗannan kayan suna ba da ƙarin sassauci, karko, da juriya ga zafin jiki da danshi.Don sassauƙan yadudduka, kayan kamar polyimide da ruwa mai kristal polymer (LCP) suna ba da kyakkyawan sassauci yayin riƙe kayan lantarki.Don yadudduka masu tsauri, kayan kamar FR4 da laminates masu zafi masu zafi na iya samar da mahimmancin mahimmanci da aminci.3D da'irori da aka buga:

Fasahar bugu ta 3D ta kawo sauyi ga masana'antu da yawa, gami da kera PCB.Ƙarfin 3D buga alamun gudanarwa kai tsaye a kan sassauƙan sassa masu sassauƙa yana ba da damar ƙarin hadaddun ƙirar PCB masu rikitarwa.Fasaha ta sauƙaƙe samfuri da gyare-gyare da sauri, ƙyale masu zanen kaya su ƙirƙiri nau'i na musamman da kuma haɗa abubuwan da aka gyara kai tsaye zuwa sassa masu sassauƙa.Yin amfani da da'irori na 3D da aka buga a cikin PCBs masu tsauri yana ƙara sassauƙar ƙira kuma yana rage hawan haɓakawa.

Abubuwan Haɗe-haɗe masu sassauƙa:

Wani babban ci gaba a cikin fasahar lamination shine haɗa kai tsaye na abubuwan haɗin kai cikin sassauƙan Layer na PCB mai sassauƙa.Ta hanyar haɗa abubuwa kamar resistors, capacitors har ma da microcontrollers a cikin sassa masu sassauƙa, masu zanen kaya na iya ƙara rage girman PCB gabaɗaya da haɓaka amincin sigina.Wannan fasaha yana ba da ƙarin ƙira mai ƙima da nauyi, yana mai da shi manufa don aikace-aikace tare da matsananciyar ƙarancin sarari.

Wutar sigina mai sauri:

Yayin da buƙatar sadarwa mai sauri ke ci gaba da girma, ci gaba a cikin fasahar lamination yana ba da damar ingantacciyar sigina mai sauri a cikin PCBs masu sassauƙa.Yi amfani da ingantattun fasahohi kamar sarrafa tashe-tashen hankula, bambance-bambancen bibiyu, da ƙirar microstrip ko tsiri don kiyaye amincin sigina da rage asarar sigina.Abubuwan la'akari da ƙira kuma suna la'akari da tasirin haɗaɗɗiya, taɗi, da tunanin sigina.Yin amfani da ƙwararrun kayan aiki da hanyoyin masana'antu suna taimakawa cimma babban aiki mai sauri na PCBs masu sassaucin ra'ayi.

Ci gaba da ci gaba a cikin fasahar lamination mai tsauri yana ba da damar haɓaka mafi ƙanƙanta, sassauƙa, da cikakkun na'urorin lantarki.Ci gaba a cikin ƙirƙira kayan ƙira, da'irori na 3D da aka buga, sassauƙan abubuwan da aka haɗa da siginar sigina mai sauri suna ba masu ƙira da sassauci da dama don ƙirƙirar ƙirar PCB masu tsauri da aminci.Kamar yadda fasaha ke ci gaba da haɓakawa, masu ƙira da masana'anta dole ne su kasance da sabuntawa kuma suyi aiki tare don cin gajiyar sabbin ci gaba da cimma ingantaccen aikin PCB mai sassauƙa.

A takaice,ƙira da zaɓar daidaitaccen daidaitaccen tsari na PCB mai tsauri yana da mahimmanci don cimma kyakkyawan aiki, aminci, da sassauci.Ta hanyar la'akari da dalilai kamar amincin sigina, buƙatun sassauƙa da ƙayyadaddun masana'anta, masu ƙira za su iya daidaita tari don biyan takamaiman bukatun aikace-aikacen su.Ci gaba da ci gaba a fasahar kayan aiki yana ba da fa'ida ga ingantaccen ƙirar lantarki.Sabbin kayan da aka keɓance don PCBs masu tsauri suna haɓaka sassauƙa, dorewa, da zafin jiki da juriya.Bugu da ƙari, haɗa abubuwan haɗin kai kai tsaye a cikin flex Layer yana ƙara rage girman da nauyin PCB, yana sa ya dace da aikace-aikace tare da matsananciyar sararin samaniya.Bugu da ƙari, ci gaban fasahar lamination yana ba da dama mai ban sha'awa.Amfani da fasahar bugu na 3D na iya ba da damar ƙira masu sarƙaƙƙiya da sauƙaƙe samfuri da gyare-gyare cikin sauri.

Bugu da kari, ci gaban fasahar sarrafa sigina mai sauri yana ba da damar PCBs masu sassauƙa don cimma ingantacciyar hanyar sadarwa mai inganci.

Yayin da fasaha ke ci gaba da haɓakawa, dole ne masu zanen kaya su kula da sabbin ci gaba kuma suyi aiki tare da masana'anta.Ta hanyar haɓaka ci gaba a cikin kayan aiki da fasahohin masana'antu, masu zanen kaya na iya ƙirƙirar sabbin ƙira mai ƙarfi na PCB don biyan buƙatun masana'antar lantarki da ke canzawa koyaushe.Tare da alƙawarin ingantattun ƙirar lantarki, makomar PCB stackups masu tsauri suna da ban sha'awa.

Lokacin aikawa: Satumba-12-2023

Baya