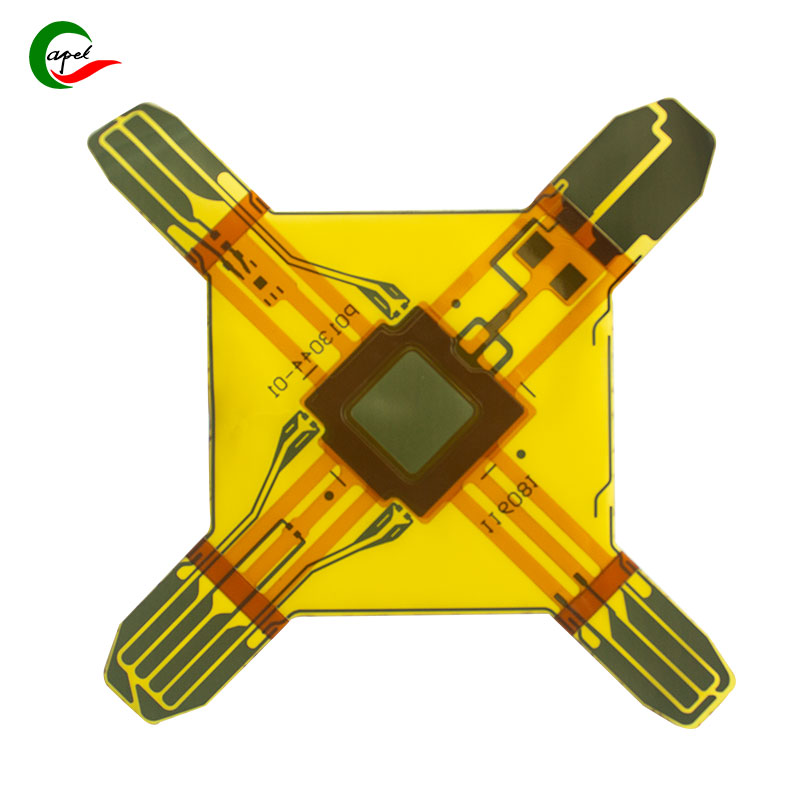

Multilayer m bugu allon allon (FPC PCBs) muhimman abubuwan da ake amfani da su a cikin na'urorin lantarki iri-iri, daga wayoyi da allunan zuwa na'urorin likita da tsarin kera motoci.Wannan fasaha ta ci gaba tana ba da sassauci mai girma, dorewa da ingantaccen watsa sigina, wanda ke sa ana nema sosai a cikin duniyar dijital mai sauri.A cikin wannan shafin yanar gizon, za mu tattauna manyan abubuwan da suka ƙunshi FPC PCB multilayer da muhimmancin su a cikin aikace-aikacen lantarki.

1. M Substrate:

M Substrate shine tushen multilayer FPC PCB.Yana ba da sassaucin da ake buƙata da amincin injina don jure lankwasa, folding da murɗawa ba tare da lalata aikin lantarki ba.Yawanci, ana amfani da kayan polyimide ko polyester azaman tushen tushe saboda kyakkyawan yanayin yanayin zafi, rufin lantarki, da ikon ɗaukar motsi mai ƙarfi.

2. Layer mai sarrafawa:

Yadudduka masu aiki sune mafi mahimmancin abubuwan haɗin FPC PCB masu yawa saboda suna sauƙaƙe kwararar siginar lantarki a cikin kewaye.Wadannan yadudduka yawanci ana yin su ne da jan ƙarfe, wanda ke da kyakkyawan ƙarfin lantarki da juriya na lalata.An makala foil ɗin tagulla zuwa madaidaicin madauri ta amfani da manne, kuma ana aiwatar da tsarin etching na gaba don ƙirƙirar ƙirar da'irar da ake so.

3. Insulation Layer:

Ana sanya yadudduka masu ɗorewa, wanda kuma aka sani da yadudduka dielectric, tsakanin yadudduka masu ɗaure don hana gajerun wando na lantarki da samar da keɓewa.An yi su da abubuwa daban-daban kamar su epoxy, polyimide ko solder mask, kuma suna da ƙarfin ƙarfin kuzari da kwanciyar hankali na thermal.Waɗannan yadudduka suna taka muhimmiyar rawa wajen kiyaye amincin sigina da hana yin magana tsakanin alamomin da ke kusa.

4. Solder mask:

Solder abin rufe fuska Layer ne mai kariya da aka yi amfani da shi ga yadudduka masu ɗaure da insulating wanda ke hana gajerun kewayawa yayin saida kuma yana kare alamun jan ƙarfe daga abubuwan muhalli kamar ƙura, danshi, da iskar oxygen.Yawanci launin kore ne amma kuma suna iya zuwa da wasu launuka kamar ja, shuɗi ko baki.

5. Mai rufi:

Coverlay, wanda kuma aka sani da fim ɗin murfi ko fim ɗin murfi, Layer ne mai kariya da aka yi amfani da shi a saman saman mafi yawan Layer FPC PCB.Yana ba da ƙarin kariya, kariya ta injiniya da juriya ga danshi da sauran gurɓatattun abubuwa.Rubutun yawanci suna da buɗaɗɗe don sanya abubuwan haɗin gwiwa da ba da izinin shiga cikin sauƙi.

6. Tagulla:

Tagulla plating shine tsarin sanya ɗan ƙaramin ƙarfe na jan ƙarfe na wutan lantarki akan wani Layer mai ɗaukar nauyi.Wannan tsari yana taimakawa haɓaka haɓakar wutar lantarki, ƙarancin ƙarfi, da haɓaka ingantaccen tsarin tsarin PCBs masu yawa FPC.Har ila yau, platin jan karfe yana sauƙaƙa kyawawan alamun da'irori masu yawa.

7. Ta hanyar:

A via wani ƙaramin rami ne da aka haƙa ta cikin yadudduka masu ɗaukar nauyi na FPC PCB mai yawan Layer, yana haɗa yadudduka ɗaya ko fiye tare.Suna ba da damar haɗin kai tsaye kuma suna ba da damar sigina ta hanyar sadarwa tsakanin yadudduka daban-daban na kewaye.Vias yawanci ana cika su da tagulla ko manna na'ura don tabbatar da ingantaccen haɗin lantarki.

8. Kunshin ɓangaren:

Pads fakitin yanki ne akan PCB FPC multilayer wanda aka keɓe don haɗa abubuwan lantarki kamar su resistors, capacitors, hadedde circuits, da connectors.Wadannan pads yawanci ana yin su ne da tagulla kuma ana haɗe su da abubuwan da ke gudana ta hanyar amfani da solder ko m.

A takaice:

A multilayer m printed board circuit (FPC PCB) wani hadadden tsari ne wanda ya kunshi abubuwa na asali da yawa.Masu sassauƙan sassauƙa, yadudduka masu ɗaukar nauyi, yadudduka masu rufewa, abin rufe fuska mai siyarwa, overlays, plating na jan karfe, vias da pads suna aiki tare don samar da haɗin wutar lantarki da ake buƙata, sassaucin inji da ɗorewa da na'urorin lantarki na zamani ke buƙata.Fahimtar waɗannan manyan abubuwan haɗin gwiwa yana taimakawa wajen ƙira da kera manyan PCB na FPC multilayer waɗanda suka dace da ƙaƙƙarfan buƙatun masana'antu daban-daban.

Lokacin aikawa: Satumba-02-2023

Baya