Lokacin zabar tsarin jiyya na saman (kamar nutsewa zinariya, OSP, da sauransu) don PCB mai Layer 3, yana iya zama ɗawainiya mai ban tsoro.Tun da akwai zaɓuɓɓuka da yawa, yana da mahimmanci don zaɓar tsarin jiyya mafi dacewa don saduwa da takamaiman bukatunku.A cikin wannan blog post, za mu tattauna yadda za a zabi mafi kyau surface jiyya for your 3-Layer PCB, nuna alama da gwaninta na Capel, a kamfanin da aka sani da ta high quality-iko da kuma ci-gaba PCB masana'antu matakai .

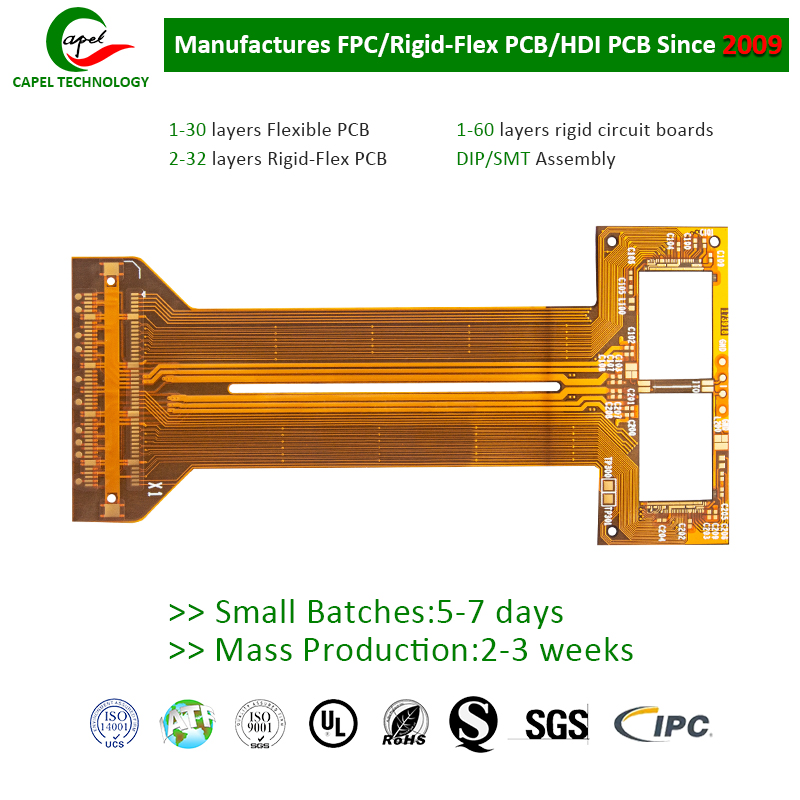

Capel ya shahara don PCBs masu tsauri, PCBs masu sassauƙa da HDI PCBs.Tare da takaddun shaida da ɗimbin yawa na ci-gaba na masana'antu na PCB, Capel ya kafa kansa a matsayin jagoran masana'antu.Yanzu bari mu dubi abubuwan da za mu yi la'akari da su lokacin zabar ƙarewar ƙasa don PCB mai Layer 3.

1. Aikace-aikace da muhalli

Na farko, yana da mahimmanci don ƙayyade aikace-aikace da muhallin PCB mai Layer 3.Daban-daban hanyoyin jiyya na saman suna ba da matakan kariya daban-daban daga lalata, iskar shaka da sauran abubuwan muhalli.Misali, idan PCB naka zai fuskanci yanayi mai tsauri, kamar zafi mai zafi ko matsanancin zafi, ana ba da shawarar zaɓin tsarin jiyya na saman da ke ba da ingantacciyar kariya, kamar zinare nutsewa.

2. Kudin da lokacin bayarwa

Wani muhimmin al'amari da za a yi la'akari da shi shine farashi da lokacin jagorar da ke hade da matakai daban-daban na jiyya na saman.Kudin kayan aiki, buƙatun aiki da lokacin samarwa gabaɗaya ya bambanta ga kowane tsari.Dole ne a kimanta waɗannan abubuwan akan kasafin kuɗin ku da lokacin aikin don yanke shawara mai fa'ida.Capel ta gwaninta a ci-gaba masana'antu matakai tabbatar kudin-tasiri da dace mafita to your PCB surface shirye-shiryen bukatun.

3. Amincewa da RoHS

RoHS (Ƙuntata Abubuwan Haɗaɗɗen Abubuwan Haɗaɗɗen Abubuwan Haɗaɗɗen Abubuwan Haɗaɗɗa) shine mabuɗin mahimmanci, musamman idan samfurin ku na kasuwar Turai ne.Wasu jiyya na saman na iya ƙunsar abubuwa masu haɗari waɗanda suka wuce iyakokin RoHS.Yana da mahimmanci a zaɓi tsarin jiyya na saman da ya dace da ƙa'idodin RoHS.Ƙaddamar da Capel na kula da inganci yana tabbatar da cewa tsarin kula da saman sa ya dace da RoHS, yana ba ku kwanciyar hankali idan ya zo ga yarda.

4. Solderability da Waya bonding

A solderability da waya bonding halaye na PCB ne muhimman la'akari.Tsarin jiyya na saman ya kamata ya tabbatar da ingantaccen solderability, yana haifar da mannewa mai dacewa a lokacin taro.Bugu da ƙari, idan ƙirar PCB ɗinku ta ƙunshi haɗin waya, tsarin jiyya na saman ya kamata ya inganta amincin igiyoyin waya.OSP (Organic Solderability Preservative) sanannen zaɓi ne saboda ingantaccen solderability ɗin sa da haɗin haɗin waya.

5. Nasiha da tallafi na masana

Zaɓin tsarin jiyya na saman da ya dace don PCB mai Layer 3 na iya zama mai rikitarwa, musamman idan kun kasance sababbi ga masana'antar PCB.Neman shawarwarin ƙwararru da goyan baya daga wani kamfani mai dogaro kamar Capel na iya sauƙaƙe tsarin yanke shawara.Ƙwararrun ƙwararrun ƙwararrun Capel za su iya jagorantar ku ta hanyar zaɓin zaɓi kuma suna ba da shawarar tsarin jiyya mafi dacewa bisa ga takamaiman bukatunku.

A taƙaice, zaɓar mafi dacewa da jiyya na saman don PCB mai Layer 3 yana da mahimmanci don ingantaccen aiki da tsawon rai.Abubuwa kamar aikace-aikace da muhalli, farashi da lokacin jagora, yarda da RoHS, solderability da haɗin waya yakamata a kimanta su a hankali.Ikon ingancin Capel, takaddun shaida da ci-gaban masana'antu na PCB suna ba shi damar saduwa da buƙatun shirye-shiryen ku.Tuntuɓi ƙwararrun Capel kuma ku amfana daga ɗimbin ilimin masana'antu da ƙwarewarsu.Ka tuna cewa a hankali zaɓaɓɓen hanyoyin jiyya na saman na iya tasiri sosai ga aikin gabaɗaya da dorewar PCB mai Layer 3.

Lokacin aikawa: Satumba-29-2023

Baya