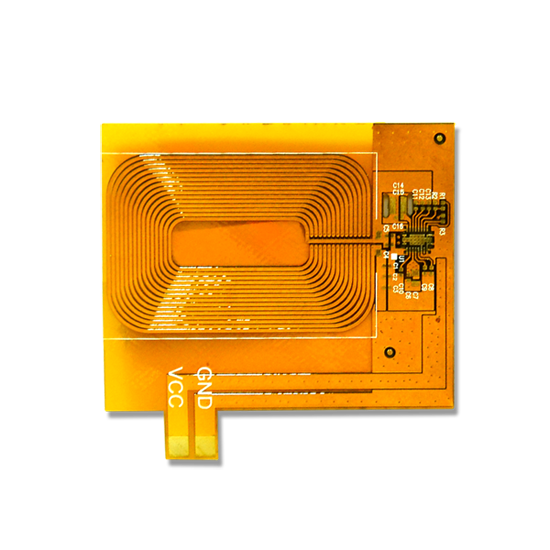

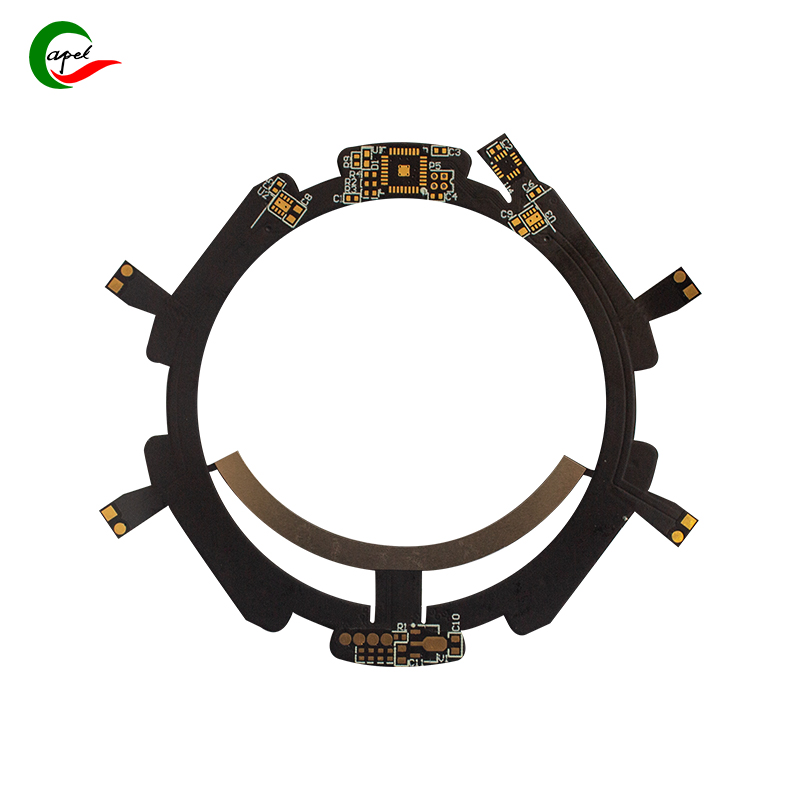

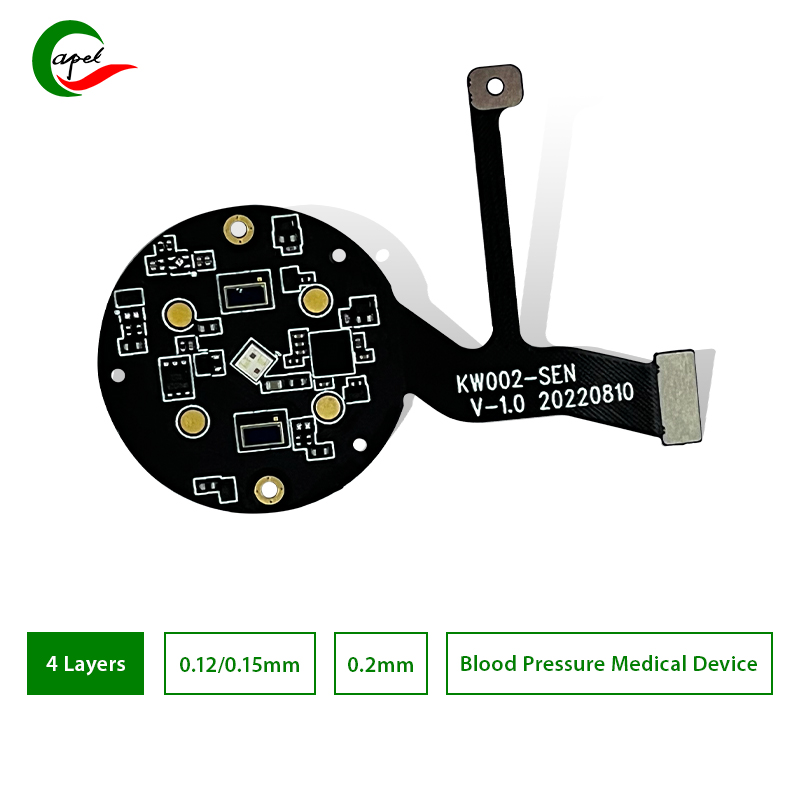

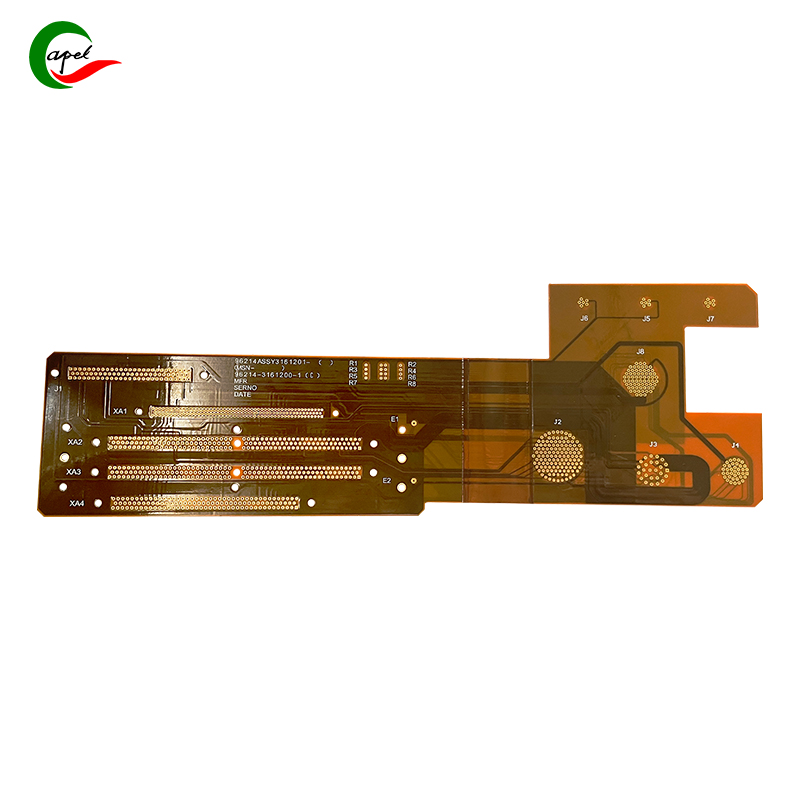

wayar hannu m lanƙwasa PCB | smartphone flex PCB kewaye allon

Wadanne matsaloli ne mafi wahala abokan ciniki na fpc eriyar wayar hannu ke buƙatar warwarewa?

-Capel tare da shekaru 15 na ƙwarewar fasaha na ƙwararru-

Babban mitar watsa sigina: Tabbatar cewa allon kewayawa na iya watsa sigina mai tsayi yadda ya kamata don guje wa tsangwama da tsangwama.

Ƙarfin tsangwama: Tabbatar da cewa sauran na'urorin lantarki ko tsangwama na lantarki ba su shafi allon kewayawa yayin amfani da wayar hannu.

Girma da nauyi: Girma da nauyin allon da'irar suna buƙatar la'akari da shi don tabbatar da ya dace da bukatun ƙirar wayar.

Sassauci da karko: Tabbatar da cewa sassauƙan allon da'ira ba ta da sauƙi a lalace lokacin lanƙwasa ko matsi, kuma yana da kwanciyar hankali na dogon lokaci.

Tasirin Kuɗi: Abokan ciniki na iya fuskantar ƙalubale waɗanda ke buƙatar daidaito tsakanin farashi da aiki.

Manufacturing: Ciki har da ingantaccen tsari samar da tsari da taro, da fasaha don tabbatar da ingancin hukumar da'ira da daidaito.

Zaɓin kayan aiki: Ana buƙatar la'akari da kayan aiki masu girma waɗanda suka dace da allon kewayawa masu sassauƙa kuma don tabbatar da amincin sarkar samarwa. Kariyar muhalli da dorewa: Tabbatar da cewa tsarin samar da allunan da'ira ya dace da buƙatun muhalli kuma zubar da allunan da'ira na iya samun dorewa.

Gwaji da tabbatarwa: Haɗe da ingantaccen gwaji da tabbatar da sassauƙan allunan kewaye don tabbatar da bin ƙayyadaddun bayanai da buƙatun aiki.

Taimakon Fasaha: Abokan ciniki na iya buƙatar samar da tallafin fasaha da mafita don magance ƙalubale da matsaloli a aikace-aikace masu amfani.

Babban mitar watsa siginar: Lokacin zayyana eriyar PCB masu sassauƙa na PCB, injiniyoyi za su yi amfani da ƙa'idodin ƙirar ƙira na manyan layin watsawa, kamar layin microstrip. Ta hanyar daidaitaccen ma'auni na impedance mai dacewa da ƙirar wayoyi, tabbatar da cewa ana iya watsa sigina masu tsayi a kan allon kewayawa tare da ƙarancin raguwa. Injiniyoyin za su yi amfani da software na kwaikwaiyo don yin mitar yanki da bincike lokaci don tabbatar da aikin watsa sigina. Misali, lokacin da injiniyoyi suka zana allunan kewayawa masu sassauƙa, suna haɓaka faɗin layi, tsayin dielectric, da kaddarorin kayan ta hanyar nazarin kwaikwaiyo don tabbatar da cewa aikin watsawa a takamaiman mitar ya cika buƙatu.

Ƙarfin katsalandan: Lokacin da ake magance matsalar iya hana tsangwama, injiniyoyi za su yi amfani da fasaha kamar ƙirar garkuwa da sarrafa waya ta ƙasa. Ta ƙara matakan kariya masu dacewa da wayoyi na ƙasa zuwa eriyar wayar hannu mai sassauci PCB, za a iya rage tsangwama na sauran siginar lantarki akan siginar eriyar wayar hannu yadda ya kamata. Haka kuma injiniyoyi na iya amfani da simulation da ainihin ma'auni don tabbatar da aikin hana tsangwama na hukumar da'ira don tabbatar da kwanciyar hankali da amincinta. Misali, a zahirin ayyuka, injiniyoyi na iya gudanar da gwaje-gwajen dacewa na lantarki akan allunan da'ira masu sassauƙa na wayar hannu don tabbatar da iyawarsu ta hana tsangwama a ainihin mahalli.

Girma da nauyi: Lokacin zana PCB mai sassauƙa don eriyar wayar hannu, injiniyoyi suna buƙatar la'akari da buƙatun ƙira na wayar hannu kuma suyi la'akari da ƙuntatawa girma da nauyi. Ta amfani da fasahohi kamar masu sassauƙan sassauƙa da ingantattun wayoyi, za a iya rage girman da nauyin allunan kewayawa yadda ya kamata. Misali, injiniyoyi na iya zabar sassauƙa mai sassauƙa tare da ƙaramin kauri da sassauƙan shimfida da'irori bisa ƙayyadaddun buƙatun ƙira na eriyar wayar hannu don rage girma da nauyin allon kewayawa.

Sassautu da karko: Don haɓaka sassauƙa da dorewa na allon kewayawa masu sassauƙa, injiniyoyi za su yi amfani da na'urori masu sassauƙa na ci gaba da hanyoyin haɗin kai. Misali, zaɓi kayan sassauƙa tare da kyawawan kaddarorin lanƙwasawa kuma yi amfani da ƙira mai haɗawa da suka dace don tabbatar da cewa allon kewayawa ba ya cikin sauƙi a lalace ƙarƙashin lankwasawa ko extrusion akai-akai. Injiniyoyin ƙila za su iya kimanta sassaucin hukumar da dorewa ta hanyar gwaji na gwaji da tabbatarwa.

Tasirin farashi: Injiniya suna haɓaka ƙira da zaɓin kayan don daidaita farashi da aiki. Misali, zaɓi kayan aiki tare da kyakkyawan aiki da matsakaicin farashi, rage amfani da kayan ta hanyar ingantaccen ƙirar wayoyi, da ɗaukar ingantattun hanyoyin masana'antu da kayan aiki mai sarrafa kansa don haɓaka haɓakar samarwa, ta haka rage farashi yayin tabbatar da aiki. A cikin ainihin ayyukan, injiniyoyi na iya amfani da kayan aikin bincike na farashi, irin su software na DFM (Design for Manufacturing), don kimanta ƙimar ƙididdiga na ƙirar ƙira da samar da abokan ciniki tare da mafi kyawun bayani.

Ƙirƙira: Injiniyoyin suna buƙatar ƙirƙira ingantaccen samarwa da tsarin taro don tabbatar da inganci da daidaiton allunan kewayawa. Misali, yayin aikin masana'antu, injiniyoyi na iya amfani da SMT (Surface Mount Technology) da na'urorin taro na atomatik don tabbatar da samar da hukumar da'ira mai inganci. Haka kuma injiniyoyi na iya tsara hanyoyin gwaji da bincike daidai gwargwado don sa ido sosai kan ingancin allunan da'ira da tabbatar da sun dace da ƙayyadaddun bayanai.

Zaɓin kayan aiki: Injiniyoyi suna buƙatar zaɓar kayan aiki masu inganci waɗanda suka dace da allunan kewayawa na eriyar wayar hannu da tabbatar da amincin sarkar samarwa. Misali, lokacin zabar kayan, injiniyoyi na iya yin la'akari da dalilai kamar su wutar lantarki akai-akai, asarar dielectric, da kaddarorin lanƙwasa na sassa masu sassauƙa, da yin shawarwari tare da masu kaya don tabbatar da samuwa da kwanciyar hankali na kayan. Injiniyoyin na iya gudanar da gwajin kayan aiki da kwatance don zaɓar mafi dacewa mafita kayan aiki.

Kariyar muhalli da dorewa: Injiniyoyi za su yi amfani da hanyoyin masana'antu masu dacewa da muhalli da zaɓin abu mai ɗorewa don tabbatar da cewa tsarin samar da eriyar FPC mai sassaucin ra'ayi PCB ya dace da bukatun muhalli. Misali, yi la'akari da aikin muhalli na kayan yayin matakin ƙira, zaɓi kayan da suka dace da umarnin RoHS, da ƙirƙira hanyoyin ƙira da za'a iya sake yin amfani da su. Hakanan injiniyoyi na iya yin aiki tare da masu ba da kaya don kafa tsarin sarkar samar da kayayyaki wanda ya dace da manufofin dorewa.

Gwaji da tabbatarwa: Injiniya za su gudanar da gwaje-gwaje daban-daban da tabbaci akan eriyar wayar hannu ta Fpc don tabbatar da cewa sun cika ƙayyadaddun bayanai da buƙatun aiki. Misali, ana amfani da kayan aikin gwaji mai tsayi don gwajin aikin watsa sigina, kuma ana amfani da na'urorin gwajin dacewa na lantarki don gwajin aikin tsangwama don tabbatar da aikin hukumar kewayawa. Hakanan injiniyoyi na iya amfani da ingantaccen kayan aikin gwaji don tabbatar da dorewa da kwanciyar hankali na allunan kewayawa.

Taimakon fasaha: Injiniyoyi za su ba da tallafin fasaha na ƙwararru da mafita lokacin da abokan ciniki ke fuskantar ƙalubalen aikace-aikacen aikace-aikacen. Misali, idan abokin ciniki ya ci karo da matsalar aiki a aikace-aikacen allon da'ira mai sassaucin eriya ta wayar hannu, injiniyan na iya gudanar da zurfafa bincike kan musabbabin matsalar, ya ba da tsarin ingantawa, da ba da tallafi da taimako a aikace. aikace-aikace. Injiniyoyin na iya ba abokan ciniki mafita da aka yi niyya ta hanyoyi daban-daban, kamar tallafin bidiyo mai nisa, jagorar fasaha a kan shafin, da sauransu.

Capel M PCB & M-Flex PCB Ƙarfin Tsari

| Kashi | Iyawar Tsari | Kashi | Iyawar Tsari |

| Nau'in samarwa | FPC guda ɗaya / Layer Layer FPC Multi-Layer FPC / Aluminum PCBs Rigid-Flex PCB | Lambar Layer | 1-30Farashin FPC 2-32yadudduka Rigid-FlexPCB1-60yadudduka Rigid PCB HDIAlloli |

| Matsakaicin Girman Masana'anta | Single Layer FPC 4000mm FPC biyu yadudduka 1200mm Multi-Layer FPC 750mm M-Flex PCB 750mm | Insulating Layer Kauri | 27.5um / 37.5/ 50um / 65/ 75um / 100um / 125um / 150um |

| Kaurin allo | FPC 0.06mm - 0.4mm M-Flex PCB 0.25 - 6.0mm | Haƙuri na PTH Girman | ± 0.075mm |

| Ƙarshen Sama | Immersion Zinariya/ nutsewa Plating Azurfa/Gold/Tin Plating/OSP | Stiffener | FR4 / PI / PET / SUS / PSA / Alu |

| Girman Orifice Semicircle | Min 0.4mm | Min Line Space/ Nisa | 0.045mm/0.045mm |

| Hakuri mai kauri | ± 0.03mm | Impedance | 50Ω-120Ω |

| Kauri Na Karfe Copper | 9um/12um/18um/35um/70um/100um | Impedance Sarrafa Hakuri | ± 10% |

| Haƙuri na NPTH Girman | ± 0.05mm | Nisa Min Flush | 0.80mm |

| Min Via Hole | 0.1mm | Aiwatar da Daidaitawa | GB / IPC-650 / IPC-6012 / IPC-6013II / Saukewa: IPC-6013I |

Capel ya keɓance madaidaiciyar madaidaiciyar madaidaiciyar madaidaiciyar madaidaiciyar madaurin kewayawa / PCB mai sassauci / HDI PCB tare da ƙwarewar shekaru 15 tare da ƙwarewarmu.

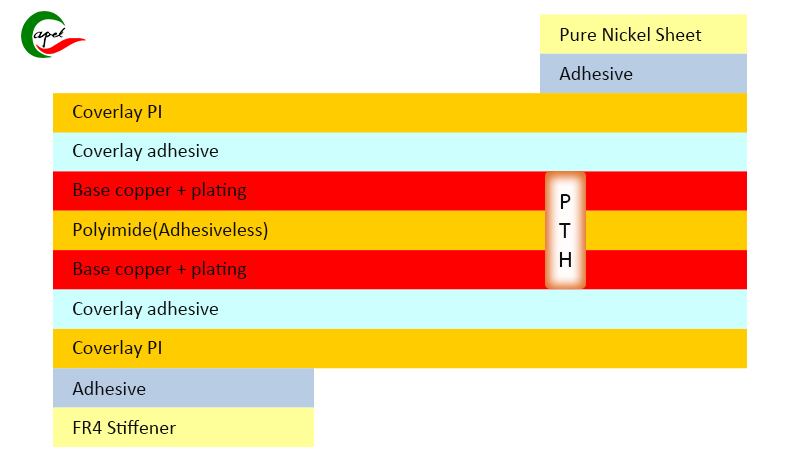

2 Layi Mai sassaucin ra'ayi na PCB Stackup

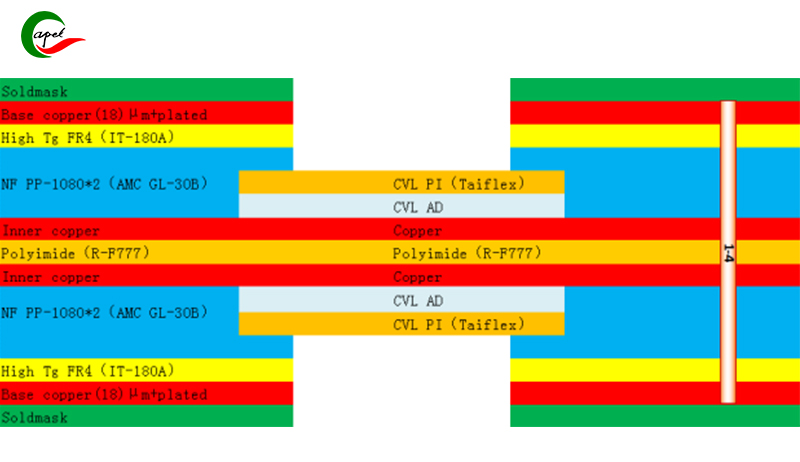

4 Layer Rigid-Flex PCB Stackup

8 Layer HDI PCBs

Gwaji da Kayan Aiki

Gwajin Microscope

Binciken AOI

Gwajin 2D

Gwajin Tashin hankali

Gwajin RoHS

Binciken Flying

Gwaji na kwance

Lankwasawa Teste

Capel yana ba abokan ciniki sabis na PCB na musamman tare da ƙwarewar shekaru 15

- Mallaka 3masana'antu don PCB mai sassauci&Rigid-Flex PCB, PCB mai ƙarfi, Majalisar DIP/SMT;

- 300+Injiniyoyin Ba da tallafin fasaha don Pre-tallace-tallace da bayan-tallace-tallace a kan layi;

- 1-30FPC Layer,2-32yadudduka Rigid-FlexPCB,1-60yadudduka Rigid PCB

- HDI Allunan, PCB mai sassauƙa (FPC), PCBs mai ƙarfi-Flex, PCBs masu yawa, PCB mai gefe guda ɗaya, allon kewayawa mai gefe biyu, katako mai fa'ida, PCB Rogers, rf PCB, PCB na ƙarfe, allon tsari na musamman, PCB Ceramic, PCB Aluminum , SMT & PTH Majalisar, PCB Prototype Service.

- Bayar24-hourPCB Prototyping sabis, Kananan Batches na kewaye allon za a isar a ciki5-7 kwanaki, Mass Production na PCB allon za a tsĩrar a2-3 makonni;

- Masana'antu da muke ba da sabis:Na'urorin likitanci, IOT, TUT, UAV, Aviation, Automotive, Sadarwa, Lantarki na Mabukaci, Soja, Aerospace, Gudanar da Masana'antu, Intelligence Artificial, EV, da dai sauransu…

- Ƙarfin Samar da Mu:

FPC da Rigid-Flex PCBs iya samar da iya isa fiye da150000 sqmkowane wata,

PCB samar iya isa80000sqmkowane wata,

PCB Haɗa iya aiki a150,000,000aka gyara kowane wata.

- Ƙungiyoyin injiniyoyinmu da masu bincike sun sadaukar da kai don cika bukatunku tare da daidaito da ƙwarewa.