Menene Babban Madaidaicin PCBs

Babban madaidaicin bugu na da'ira, wanda kuma aka sani da babban madaidaicin bugu na kewayawa,

wani bangaren lantarki ne wanda ake amfani da shi sosai a aikace-aikacen da ke buƙatar ingantattun da'irori.

An tsara waɗannan PCBs kuma an kera su tare da kulawa mai zurfi ga daki-daki, suna tabbatar da mafi girman matakin daidaito da aminci.

Ana amfani da PCB masu inganci sosai a masana'antu kamar sararin samaniya, kayan aikin likita, sadarwa, da motoci. Suna da mahimmanci musamman a aikace-aikacen da ke buƙatar madaidaicin siginar sigina, babban aikin mitar, jure juriya, da haɗin fasaha na ci gaba.

Waɗannan PCBs galibi ana kera su ne ta amfani da matakai na ci-gaba da dabaru irin su na'urorin da ke sarrafa impedance, kayan aikin farar kyau, micro vias, makafi da binne vias, da manyan haɗin kai. Hakanan suna iya haɗawa da yadudduka da yawa, hadaddun da'irori da kayayyaki na musamman don biyan takamaiman buƙatun aikace-aikacen da aka yi niyya.

Tsarin masana'anta na PCB masu inganci ya ƙunshi tsauraran matakan sarrafa inganci, gami da tsauraran gwaji da hanyoyin dubawa, don tabbatar da cewa samfurin ƙarshe ya cika ƙayyadaddun da ake buƙata. Wannan daidaito da daidaito yana ba da damar aiki mai inganci kuma abin dogaro, musamman a cikin hadadden tsarin lantarki.

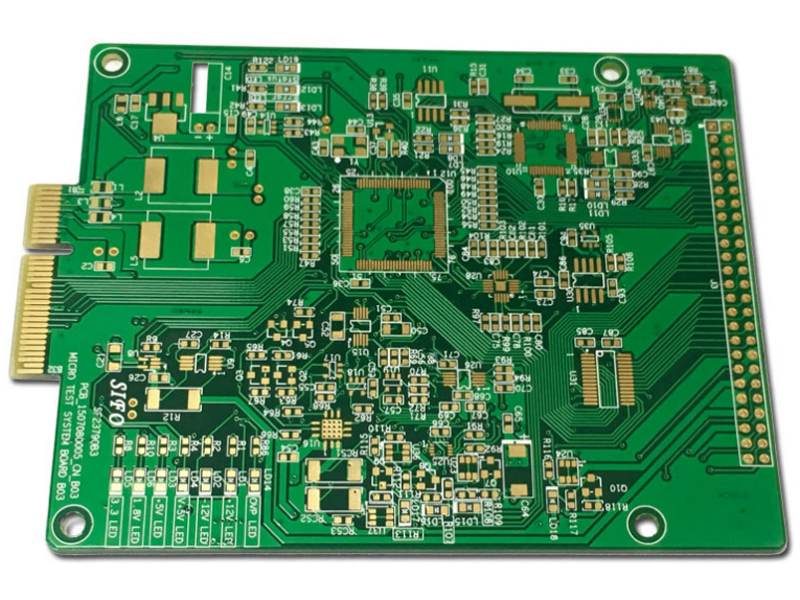

CAPEL Babban Madaidaicin PCBs

An ƙera PCBs masu inganci don samar da amintattun hanyoyin haɗin lantarki. Suna gudanar da matakai daban-daban na masana'antu kuma suna bin ƙayyadaddun ƙira da ƙa'idodin gwaji don saduwa da takamaiman buƙatun aikace-aikace masu buƙata a masana'antu daban-daban.

Kayayyakin inganci masu inganci

Ana yin PCB masu inganci galibi ta amfani da kayan inganci, kamar ƙwararrun laminates masu sauri ko tukwane na ci gaba. Waɗannan kayan suna da ƙayyadaddun kaddarorin da ke taimakawa haɓaka aikin lantarki na PCB da amincin sigina.

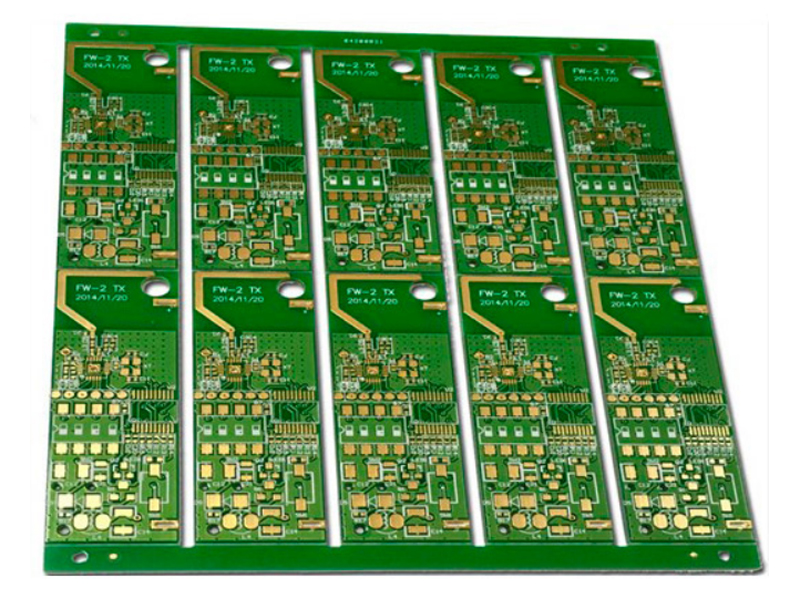

Tsarin Multi-Layer

Madaidaicin PCBs yawanci suna da tsari mai nau'i-nau'i da yawa, yana ba da damar ƙarin hadaddun da ƙira mai yawa. Gine-gine mai yawa yana taimakawa inganta keɓewar sigina, rage yawan magana da haɓaka rarraba wutar lantarki.

Layi mai kyau da sarari

Madaidaicin PCBs galibi suna buƙatar layi mai kyau da faɗin sarari, yawanci ana auna su cikin microns. Waɗannan ƙunƙuntattun alamun suna ba da damar ingantacciyar hanyar sigina da rage asarar sigina ko tsangwama.

Tsanani Mai Sarrafa

Sarrafa impedance yana da mahimmanci don kiyaye amincin sigina a aikace-aikace masu sauri. Madaidaicin PCB yana sarrafa maƙarƙashiyar gabaɗayan alamar don dacewa da ƙayyadaddun yanayin da ƙira ke buƙata.

Babban Fasaha

Madaidaicin PCBs yawanci suna amfani da fasahar masana'anta na ci gaba kamar hakowar Laser da hoto kai tsaye. Hakowa Laser yana ba da damar ƙarami, mafi daidai ta hanyar girma, yayin da hoton kai tsaye yana ba da damar ingantaccen rajistar abin rufe fuska.

Gwaji da Dubawa

Kula da inganci yana da mahimmanci ga madaidaicin PCBs. Ana amfani da tsauraran gwaje-gwaje da hanyoyin dubawa kamar duban gani mai sarrafa kansa (AOI) da duban X-ray don gano duk wani lahani ko al'amura masu yuwuwa da tabbatar da cewa PCB ya cika ƙayyadaddun da ake buƙata.

Zane don Manufacturability

Madaidaicin PCBs suna buƙatar cikakken la'akari DFM yayin lokacin ƙira don tabbatar da cewa ana iya kera ƙira da inganci kuma daidai. Dabarun DFM suna taimakawa haɓaka ƙirar ƙirar masana'anta da haɓaka yawan amfanin ƙasa gabaɗaya.

Ƙananan Abubuwan da aka Rarraba

Ana tsara manyan madaidaicin PCBs sau da yawa don ɗaukar ƙanƙantar abubuwan da suka dace kamar tsarin ɗorawa na microelectromechanical (MEMS). Madaidaicin jeri da siyar da waɗannan ƙananan abubuwan haɗin gwiwa suna ba da gudummawa ga cikakkiyar daidaito da aikin PCB.