Single-Side M PCBs Supplier China PCB Prototype

Ƙayyadaddun bayanai

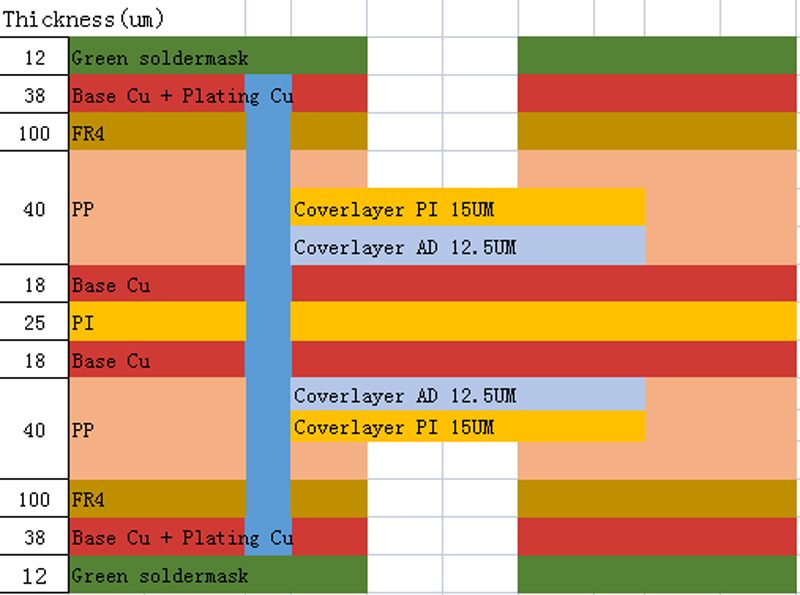

| Kashi | Iyawar Tsari | Kashi | Iyawar Tsari |

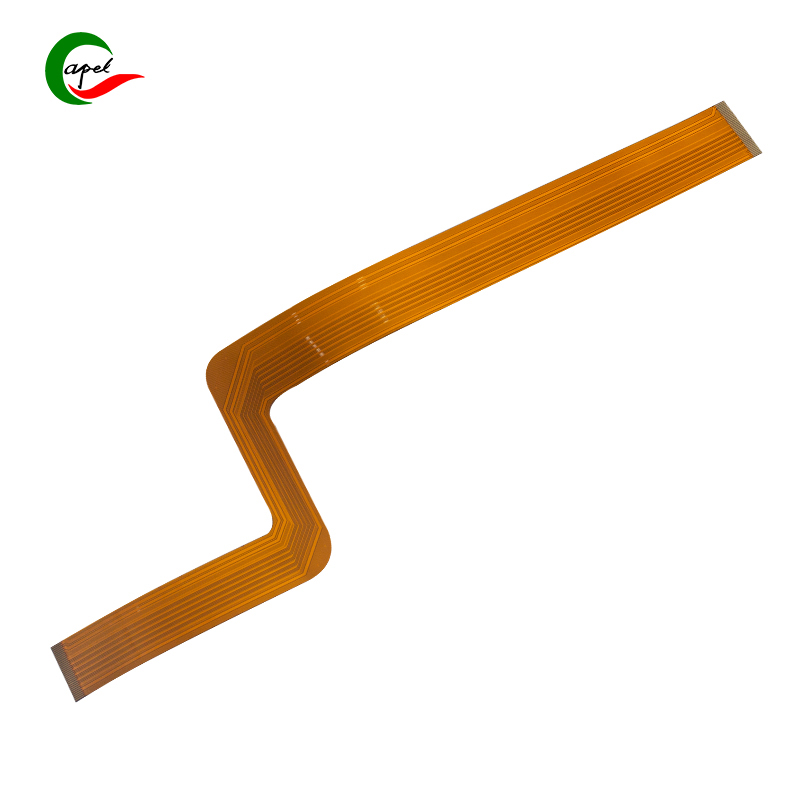

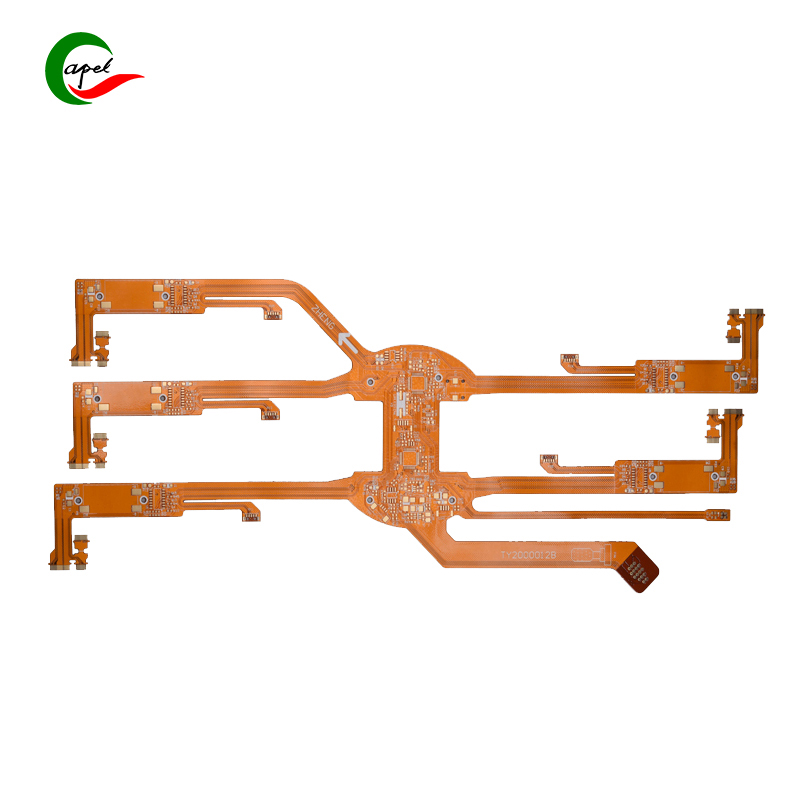

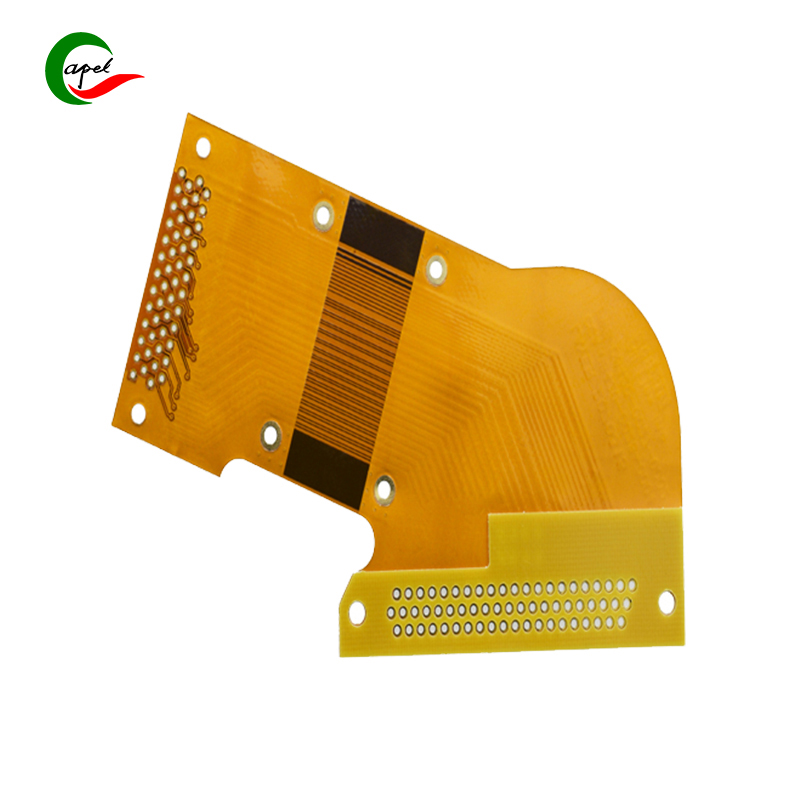

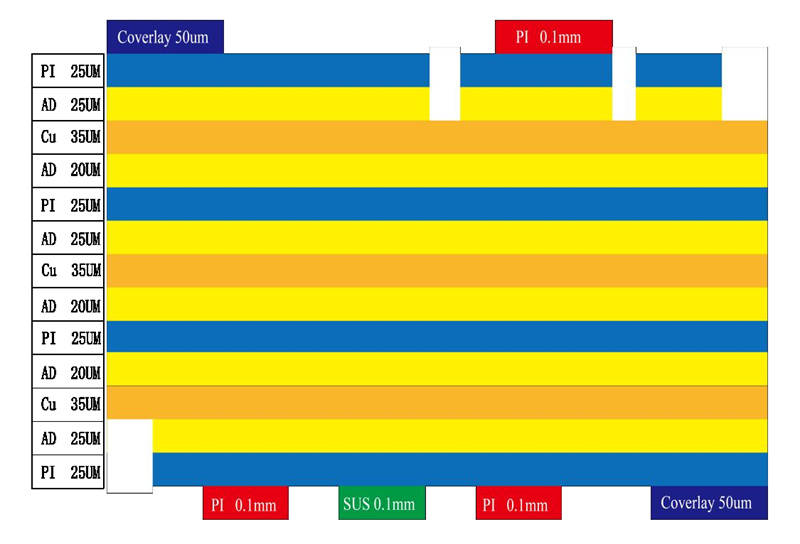

| Nau'in samarwa | FPC guda ɗaya / Layer Layer FPC Multi-Layer FPC / Aluminum PCBs PCBs masu ƙarfi-Flex | Lambar Layer | 1-16 yadudduka FPC 2-16 yadudduka Rigid-FlexPCB HDI Printed Allolin Da'ira |

| Matsakaicin Girman Masana'anta | Single Layer FPC 4000mm Doulbe Layer FPC 1200mm Multi-Layer FPC 750mm M-Flex PCB 750mm | Insulating Layer Kauri | 27.5um / 37.5/ 50um / 65/ 75um / 100um / 125um / 150um |

| Kaurin allo | FPC 0.06mm - 0.4mm M-Flex PCB 0.25 - 6.0mm | Haƙuri na PTH Girman | ± 0.075mm |

| Ƙarshen Sama | Immersion Zinariya/ nutsewa Azurfa/Gold Plating/Tin Plat ing/OSP | Stiffener | FR4 / PI / PET / SUS / PSA / Alu |

| Girman Orifice Semicircle | Min 0.4mm | Min Line Space/ Nisa | 0.045mm/0.045mm |

| Hakuri mai kauri | ± 0.03mm | Impedance | 50Ω-120Ω |

| Kauri Na Karfe Copper | 9um/12um/18um/35um/70um/100um | Impedance Sarrafa Hakuri | ± 10% |

| Haƙuri na NPTH Girman | ± 0.05mm | Nisa Min Flush | 0.80mm |

| Min Via Hole | 0.1mm | Aiwatar da Daidaitawa | GB / IPC-650 / IPC-6012 / IPC-6013II / Saukewa: IPC-6013I |

Muna yin PCB Prototype tare da ƙwarewar shekaru 15 tare da ƙwarewarmu

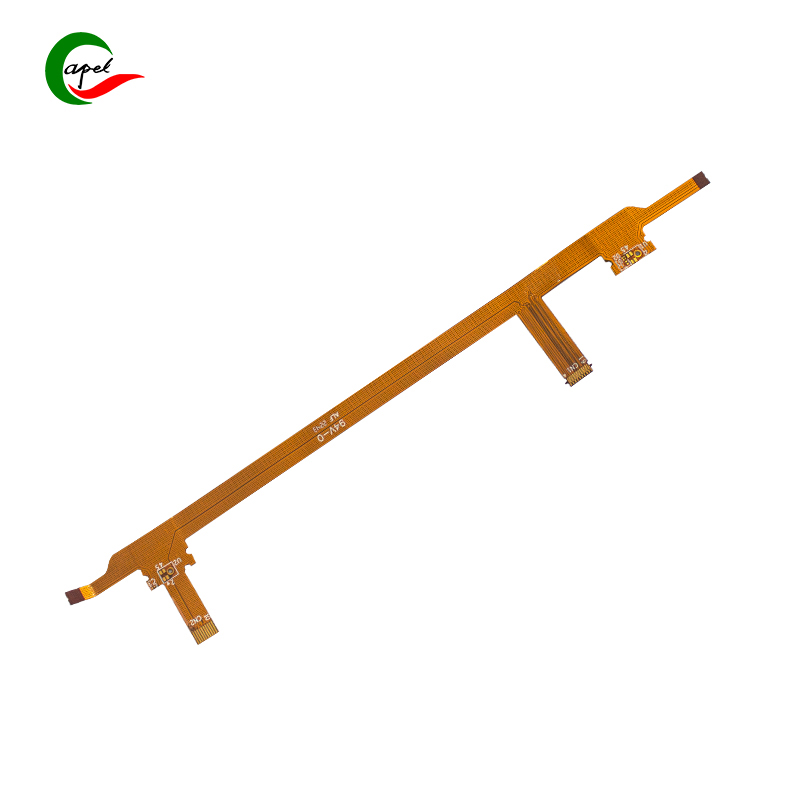

3 Layer Flex PCBs

4 Layer Rigid-Flex PCBs

8 Layer HDI Buga Allolin da'ira

Gwaji da Kayan Aiki

Gwajin Microscope

Binciken AOI

Gwajin 2D

Gwajin Tashin hankali

Gwajin RoHS

Binciken Flying

Gwaji na kwance

Lankwasawa Teste

Sabis ɗin Samfurin mu na PCB

.Bayar da goyon bayan fasaha Pre-tallace-tallace da bayan-tallace-tallace;

.Custom har zuwa 40 yadudduka, 1-2days Saurin jujjuya abin dogaro da samfur, samarwa jama'a, Sayen kayan aikin, Majalisar SMT;

.Yana ba da na'urar lafiya duka, Kula da Masana'antu, Motoci, Jirgin Sama, Lantarki na Mabukaci, IOT, UAV, Sadarwa da sauransu.

.Ƙungiyoyin injiniyoyinmu da masu bincike sun sadaukar da kai don cika bukatunku tare da daidaito da ƙwarewa.

Menene bambance-bambancen fasaha tsakanin PCB mai sassauƙan gefe guda ɗaya da allunan kewaye mai sassauƙa mai gefe biyu?

PCBs masu sassaucin ra'ayi mai gefe guda suna da madauri mai ɗaukar nauyi a gefe ɗaya na kayan aikin.Abubuwan da ke yawanci suna hawa a wannan gefen, yayin da ɗayan gefen ya kasance ba ya aiki.Alamomin da aka yi amfani da su galibi ana yin su ne da tagulla kuma ana iya yin su ta amfani da dabarun ƙirƙira iri-iri kamar etching.

Allolin da'ira masu sassauƙa masu gefe biyu, a gefe guda, suna da yadudduka masu ɗaure kai a ɓangarorin biyu na ƙasa.

Wannan yana ba da damar shigar da abubuwan haɗin gwiwa a bangarorin biyu, yana haɓaka haɓakar kayan aikin gabaɗaya da aikin hukumar.Za'a iya haɗa hanyoyin haɗin kai ta hanyar amfani da plated ta cikin ramuka (PTHs) ko vias, yana ba da damar haɗin lantarki tsakanin saman sama da ƙasa.

Wani maɓalli mai mahimmanci shine PCB mai sassauƙan gefe guda ɗaya gabaɗaya ya fi tsada-tasiri kuma mafi sauƙin ƙira fiye da mai gefe biyu.Saboda ƙarin ɗab'in gudanarwa da yuwuwar amfani da PTH ko vias, flex mai gefe biyu yawanci ya fi rikitarwa, yana buƙatar ingantaccen tsarin masana'anta, don haka yana ɗan tsada.

Me yasa ake buƙatar samfurin PCB mai sauri?

1. Ƙididdigar ƙananan ƙananan ƙira: Tsarin PCB mai sauri yana ba da damar gudanar da samar da ƙananan ƙira, wanda zai iya zama mai tsada don ƙaddamar da samfurin farko, kasuwanni masu mahimmanci, ko ƙayyadaddun bukatun samarwa.

Yana kawar da buƙatar manyan saka hannun jari na gaba a cikin kayan aikin samar da yawa, kayan aiki, da ƙira.

2. Haɗin kai da amsawa: Samfurin PCB mai sauri yana ba injiniyoyi damar haɗin gwiwa tare da masu ruwa da tsaki, gami da abokan ciniki, ƙungiyoyin ƙira, da masana'antun, mafi inganci.Ta hanyar samun samfurori na jiki a hannu, za su iya tattara bayanai masu mahimmanci da shigarwa daga bangarori daban-daban, wanda zai haifar da ingantattun gyare-gyaren ƙira da sakamakon samfurin ƙarshe.

3. Rage lokaci zuwa kasuwa: Tare da samfurin PCB mai sauri, injiniyoyi na iya rage yawan sake zagayowar ci gaban samfur, rage lokacin da ake ɗauka don kawo samfur zuwa kasuwa.Wannan yana bawa 'yan kasuwa damar cin gajiyar damar kasuwa, tsayawa gaban masu fafatawa, da samar da kudaden shiga cikin sauri.

4. Sassauci a cikin canje-canjen ƙira: PCB Prototype yana ba da sassauci don haɗa canje-canjen ƙira da haɓakawa cikin tsarin haɓakawa.Injiniyoyin na iya yin saurin gyarawa da ƙididdigewa akan ƙirar PCB, yin gyare-gyare dangane da sakamakon gwaji, ra'ayoyin abokin ciniki, ko ƙuntatawar ƙira.Wannan ƙarfin aiki yana taimakawa haɓaka ƙirar samfurin ƙarshe, haɓaka aikinta da aikinta.

5. Inganta sadarwa tare da masana'antun: Saurin-juya samfurin PCB ya haɗa da yin aiki tare da masana'antun PCB, haɓaka mafi kyawun sadarwa da haɗin gwiwa tsakanin ƙungiyoyin ƙira da masu kaya.Wannan haɗin gwiwa na kusa yana sauƙaƙe ƙira don ƙira (DFM), inda injiniyoyi za su iya haɓaka ƙira don tabbatar da masana'anta mai santsi da guje wa abubuwan samarwa ko jinkiri.

6. Koyo da haɓaka fasaha: PCB Prototype yana ba injiniyoyi damar samun ƙwarewar hannu mai mahimmanci a cikin taron PCB da tafiyar matakai.Yana taimaka musu su fahimci sarƙaƙƙiya da ɓangarori na samarwa na PCB, wanda ke haifar da ingantattun shawarwarin ƙira, ingantattun ayyukan DFM, da haɓaka ƙwarewar injiniya gabaɗaya.