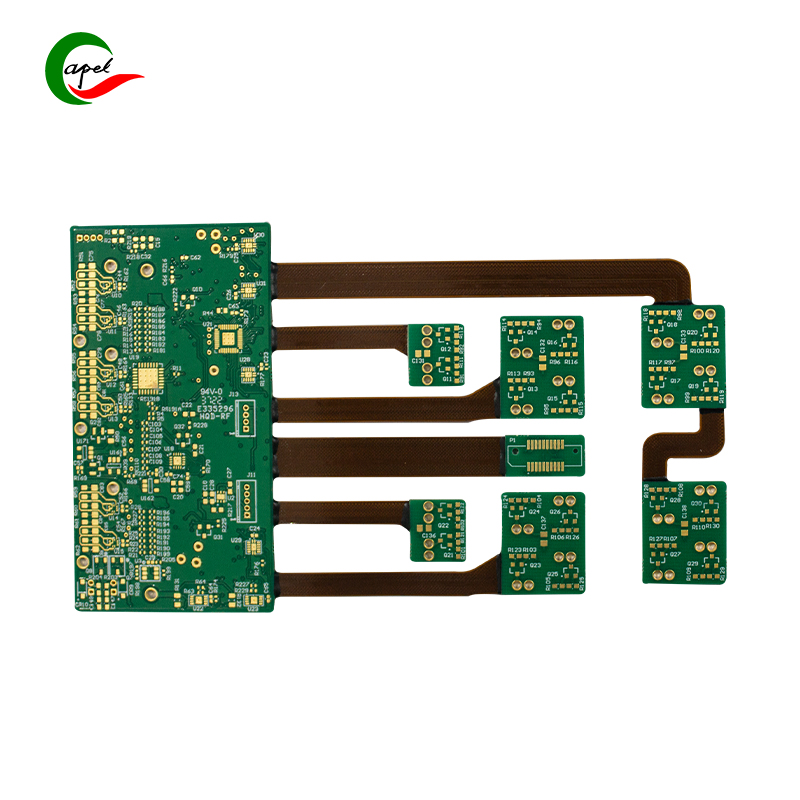

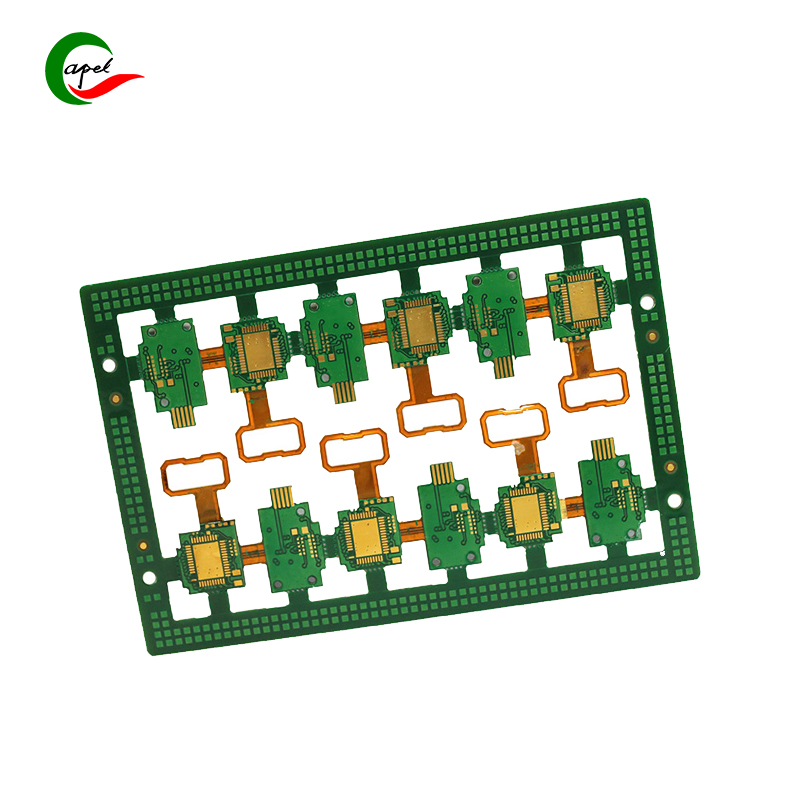

Sabis na Kera PCB mai ƙarfi-Flex

Ƙwararrun ƙwararrun ƙwararrun ƙwararrun ƙwararrun ƙwararrun hukumar da'ira mai sassauƙa ta Capel na shekaru 15

- ba da basira mai mahimmanci da jagora ga abokan cinikinmu;

- zurfin fahimtar fasahohin fasaha na fasaha na hukumar da'ira mai tsauri yana ba su damar ba da mafita waɗanda suka dace da buƙatun kowane abokin ciniki.

-haɗa fasahar yanke-tsaye da ƙa'idodin ƙira a cikin samfuran su, yana tabbatar da abokan cinikin Capel sun karɓi allunan da'ira na zamani na zamani waɗanda suka cika ko wuce matsayin masana'antu.

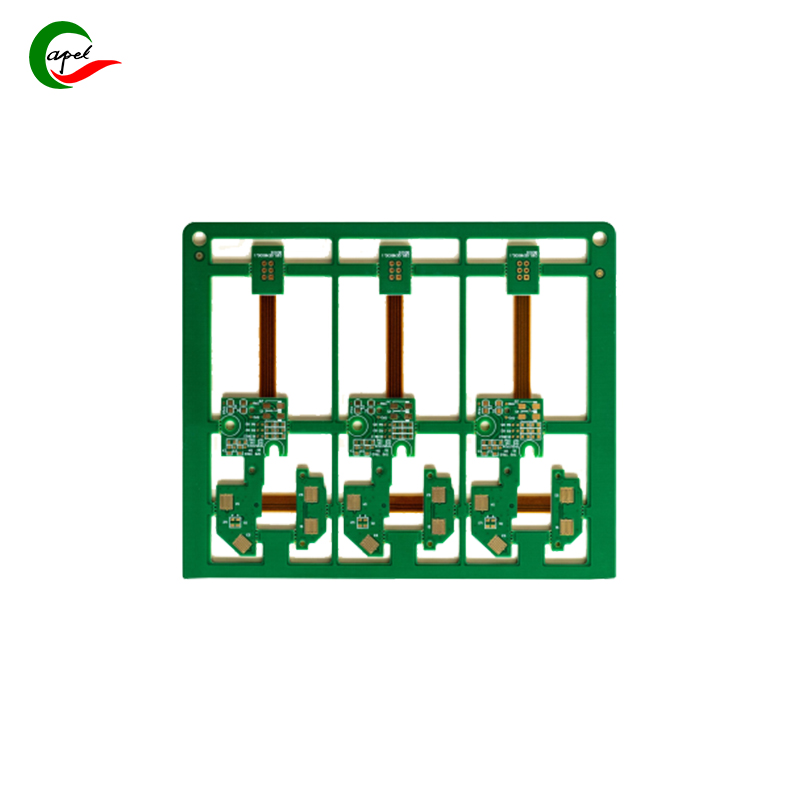

M-Flex PCBs iya samar da iya isa fiye da 70000sqm kowane wata

--sarrafa oda mai girma da kuma saduwa da jadawalin samarwa. Ko kuna buƙatar ƙarami ko babba, za mu iya cika buƙatun ku cikin sauri da inganci.

Goyan bayan musamman 2-32 Layer high-daidaici m m PCb kewaye hukumar

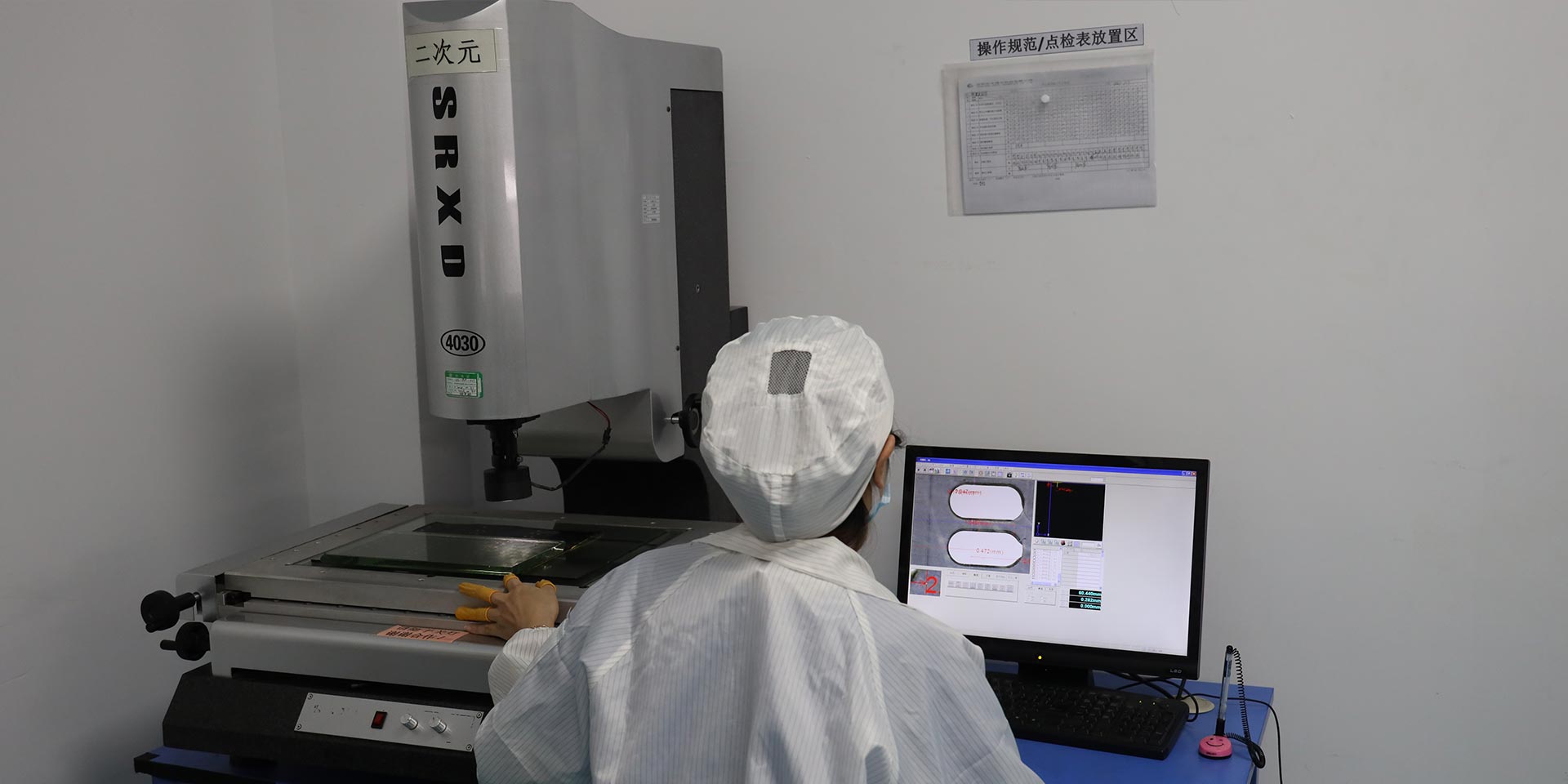

-ci-gaba da fasaha, kayan aiki, da kuma matakai don tabbatar da ingantaccen kuma abin dogara samar. Hankalin mu ga daki-daki, tsauraran matakan sarrafa inganci, da cikakkiyar gwaji suna taimaka mana isar da ingantattun PCBs masu sassauƙa masu inganci waɗanda suka dace da mafi girman matsayin masana'antu.

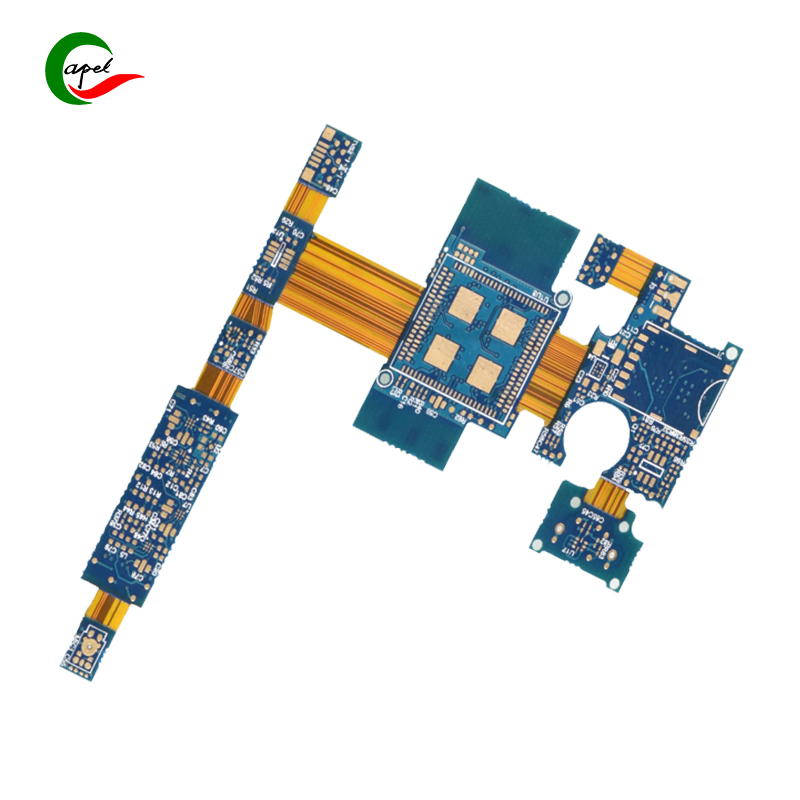

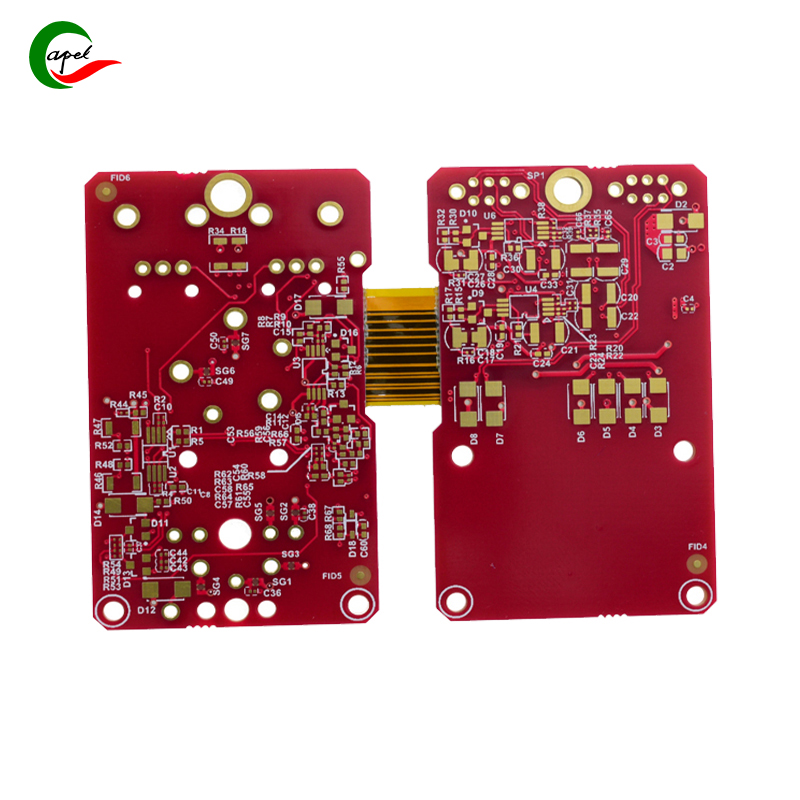

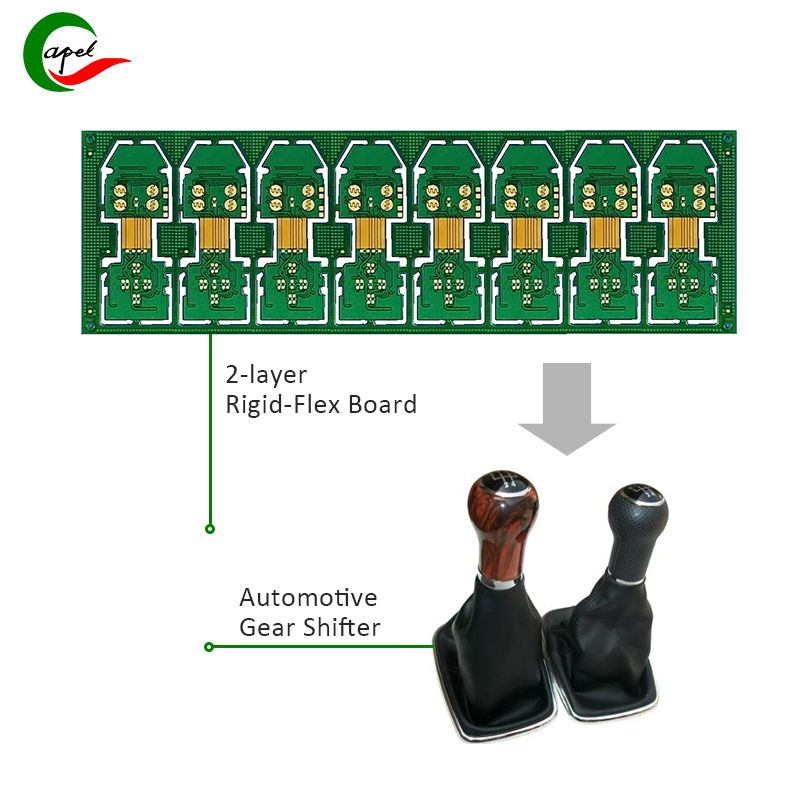

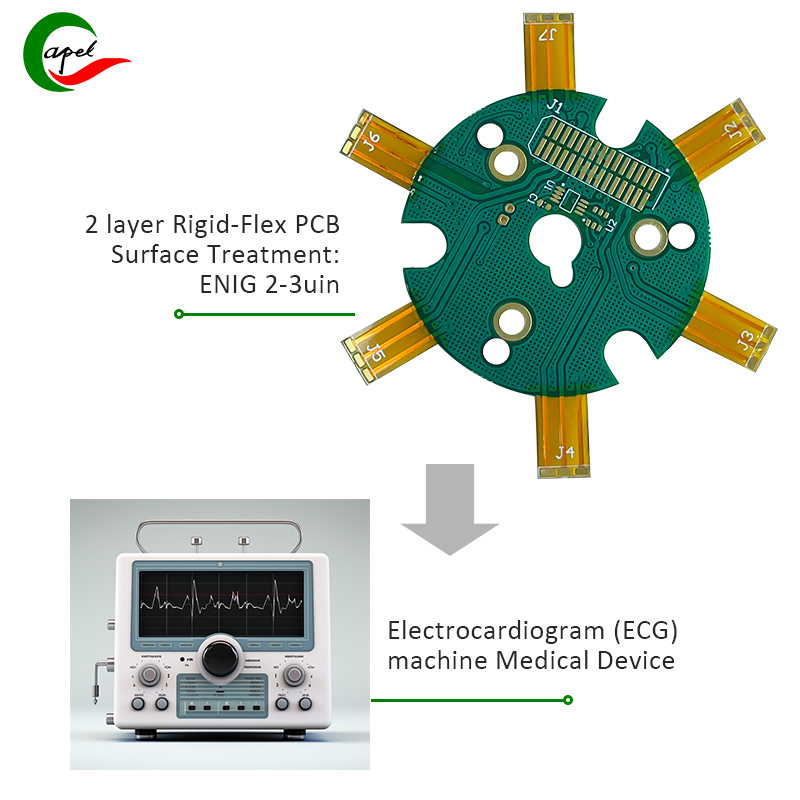

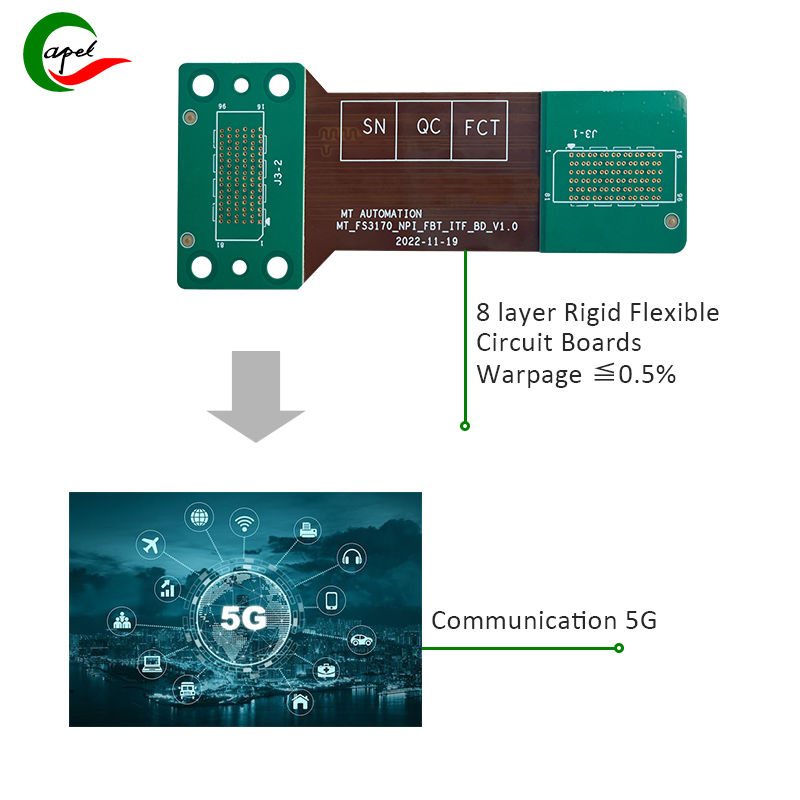

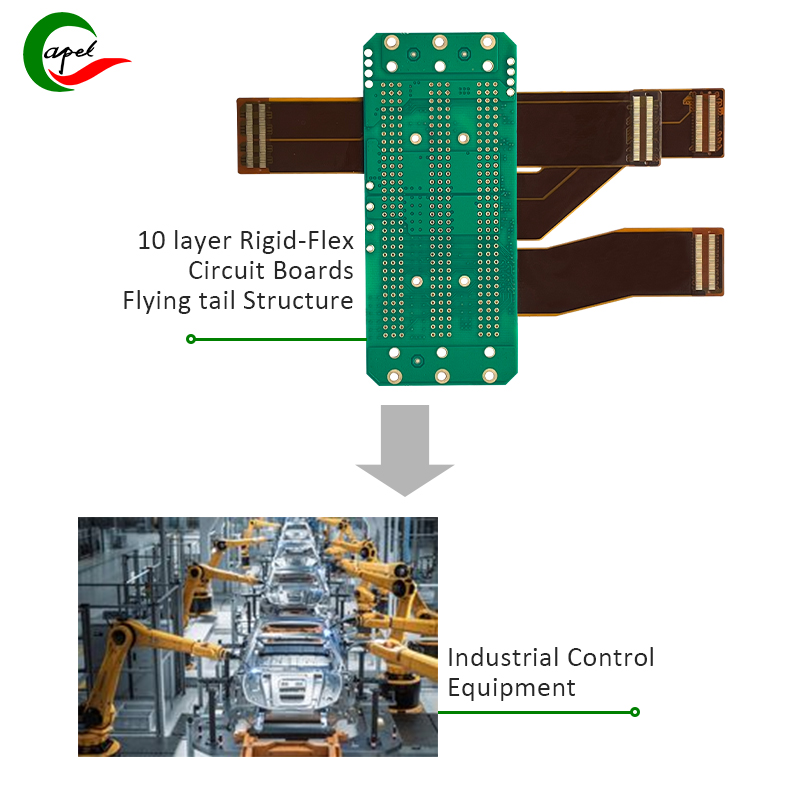

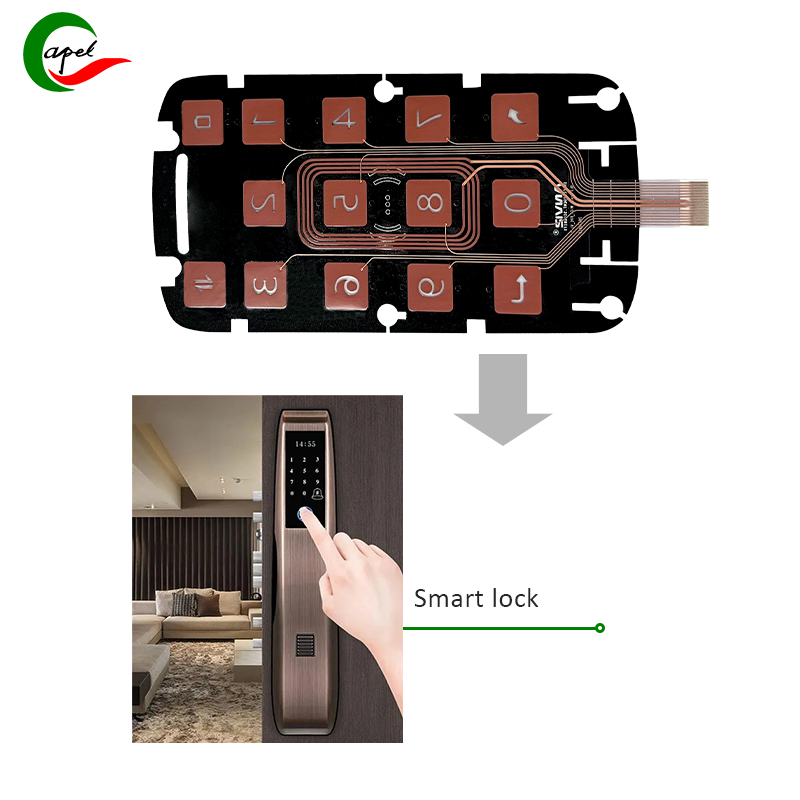

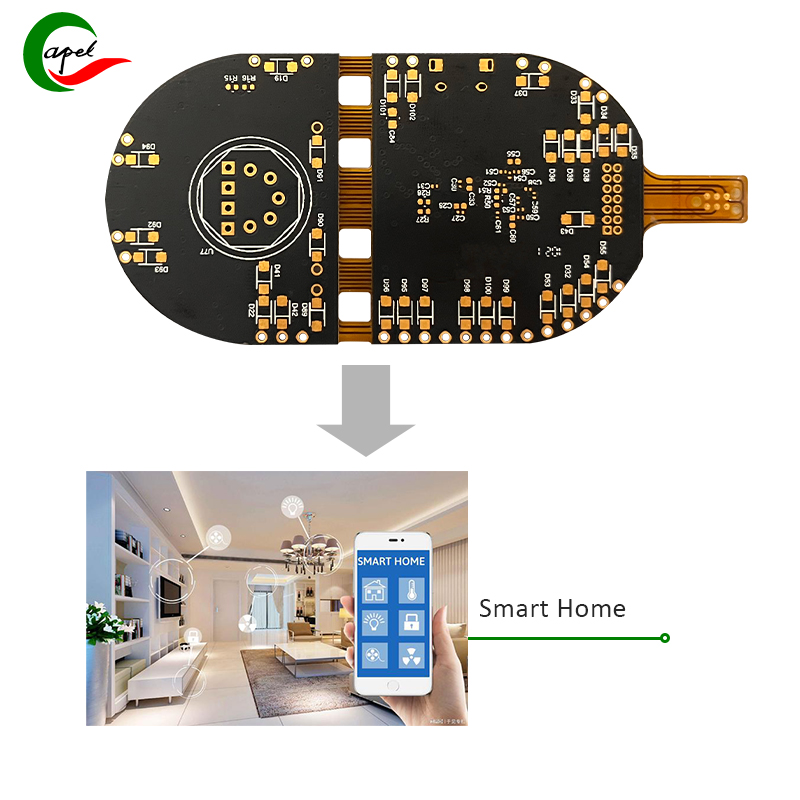

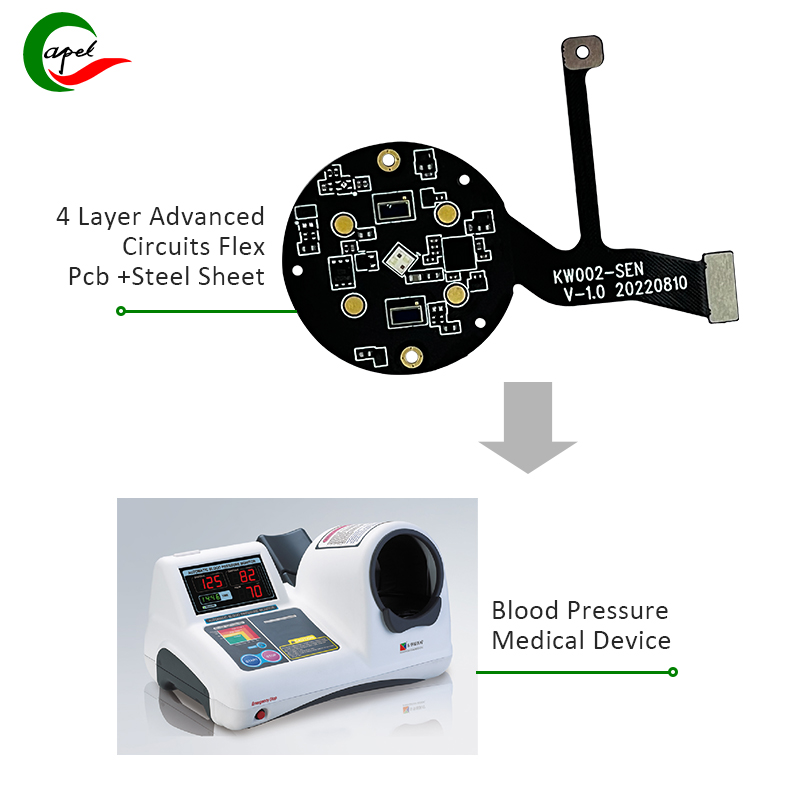

Abubuwan Aikace-aikace Na Rigid-Flex PCB Circuit Boards

Samar da ingantattun mafita a cikin kera kwamitocin da'ira mai tsauri ga abokan ciniki a cikin na'urori masu sawa, kayan aikin likitanci, sararin samaniya da tsarin tsaro, tsarin kera motoci, na'urorin lantarki, kayan sarrafa masana'antu, da sadarwa.

-Kwararren PCBs masu sassaucin ra'ayi waɗanda suka dace da takamaiman buƙatun su;

-Ya danganta da ƙayyadaddun buƙatun ku na masana'antu, za mu iya samar da allunan da'irar bugu masu ƙarfi tare da kayan musamman kamar kayan juriya masu zafi don aikace-aikacen motoci da sararin samaniya, da kayan aikin likita don aikace-aikacen na'urar likita. Hakanan muna ci gaba da sabuntawa tare da sabbin fasahohin masana'anta na PCB masu ƙarfi don biyan buƙatun waɗannan masana'antu.

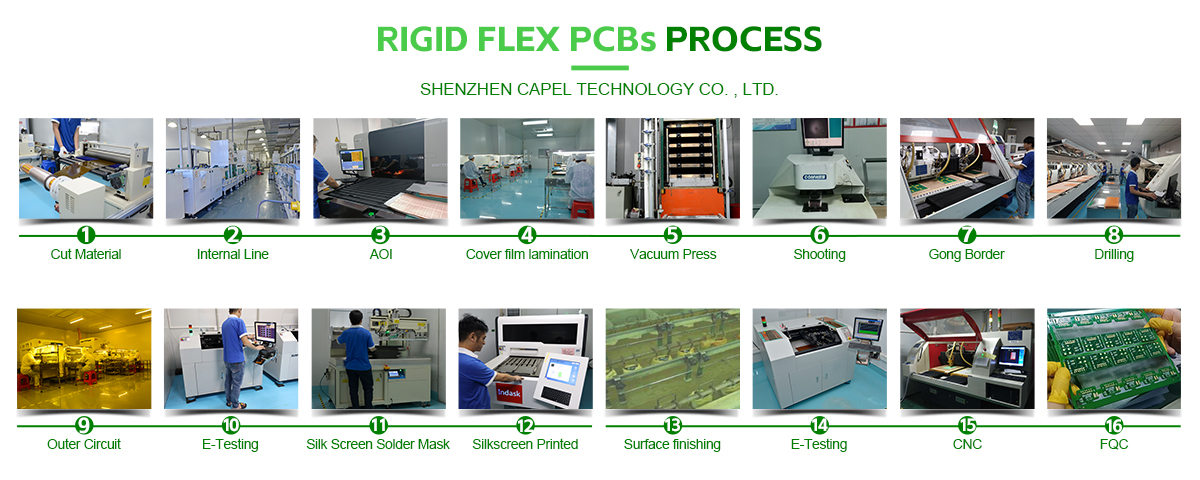

Tsari Tsari Mai Sauƙi na PCB

1. Yanke:Yanke kayan tushe mai wuyar gaske: Yanke babban yanki na katako mai sanye da tagulla zuwa girman da ƙira ke buƙata.

2. Yanke sassauƙan kayan tushe na allo:Yanke kayan mirgine na asali (kayan tushe, manne mai tsabta, fim ɗin rufewa, ƙarfafa PI, da dai sauransu) cikin girman da ake buƙata ta ƙirar injiniya.

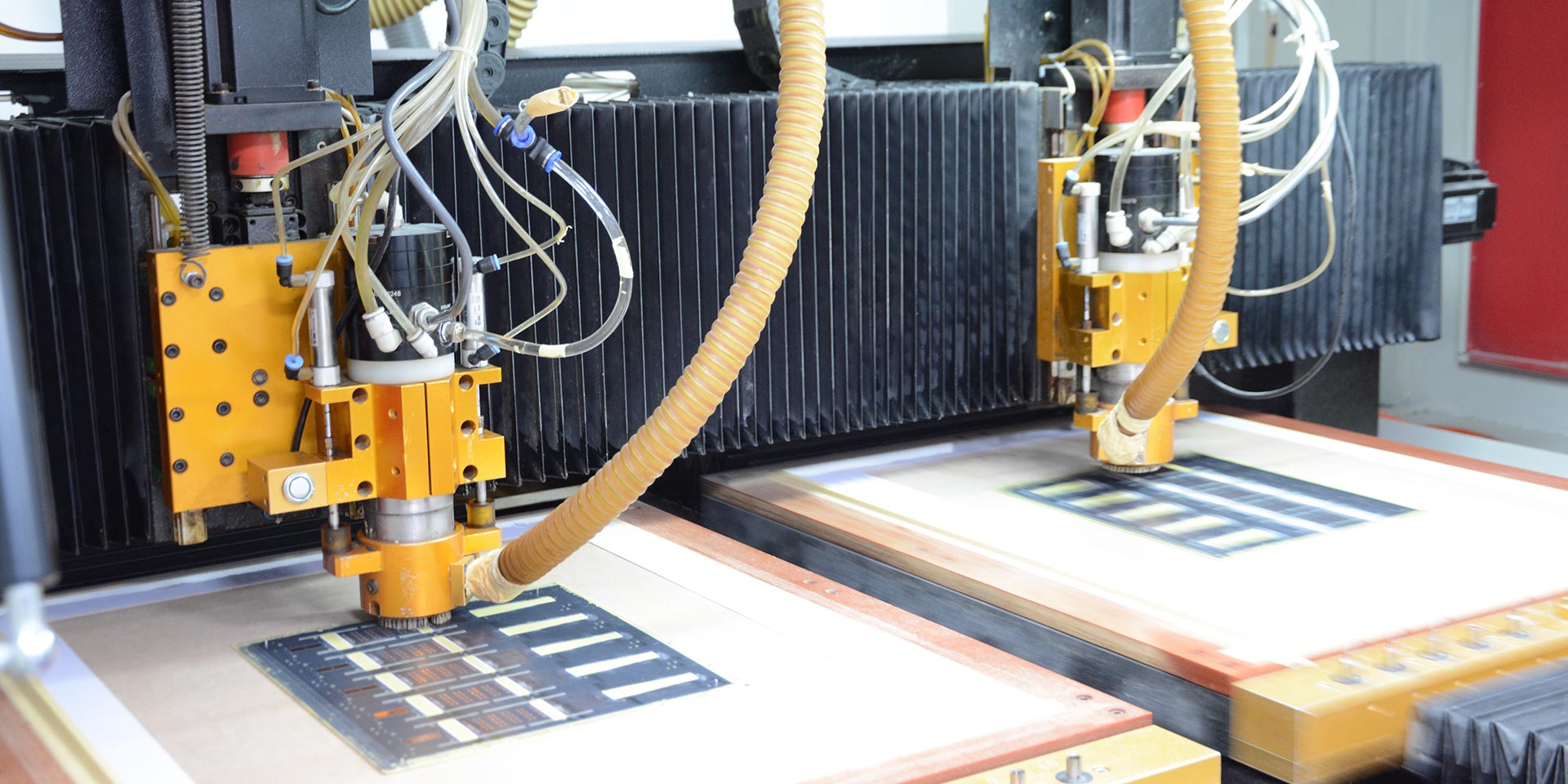

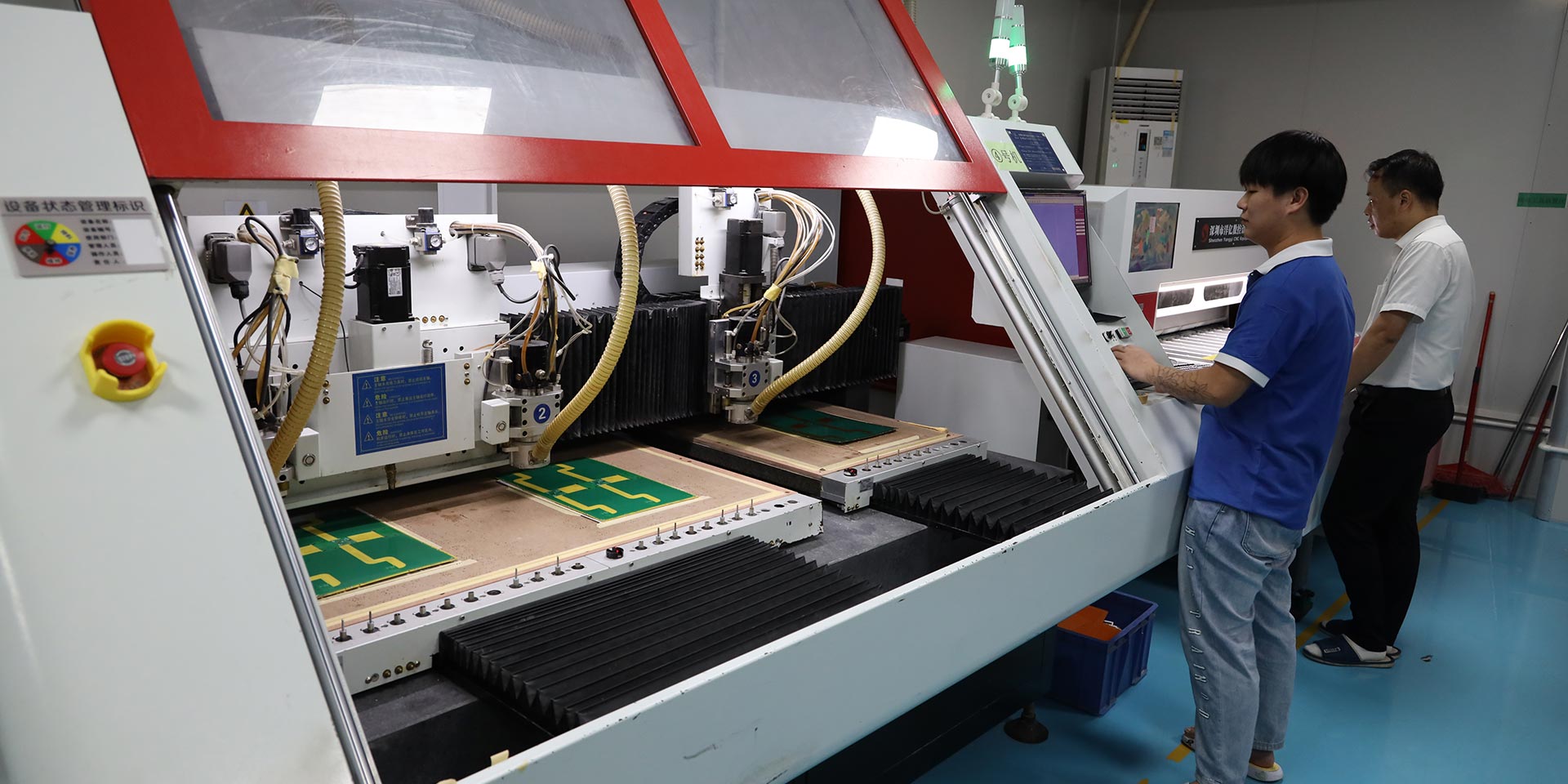

3. Hakowa:Hana ta ramuka don haɗin da'ira.

4. Baki:Yi amfani da potion don yin toner da ke manne da bangon rami, wanda ke taka muhimmiyar rawa wajen haɗawa da gudanarwa.

5. Rufe tagulla:Sanya Layer na jan karfe a cikin rami don cimma daidaituwa.

6. Fitowar daidaitawa:Daidaita fim ɗin (mara kyau) a ƙarƙashin madaidaicin matsayi na rami inda aka liƙa fim ɗin busassun don tabbatar da cewa tsarin fim ɗin zai iya daidaita daidai da saman allo. An canza tsarin fim ɗin zuwa fim ɗin busassun a kan saman jirgi ta hanyar ka'idar hoton haske.

7. Ci gaba:Yi amfani da potassium carbonate ko sodium carbonate don haɓaka fim ɗin busassun a cikin wuraren da ba a bayyana ba na tsarin kewayawa, barin busassun tsarin fim a cikin fili.

8. Tsokaci:Bayan da aka haɓaka tsarin kewayawa, filin da aka fallasa na jan karfe yana ɓoye ta hanyar maganin etching, yana barin tsarin da busassun fim ya rufe.

flex pcb taro

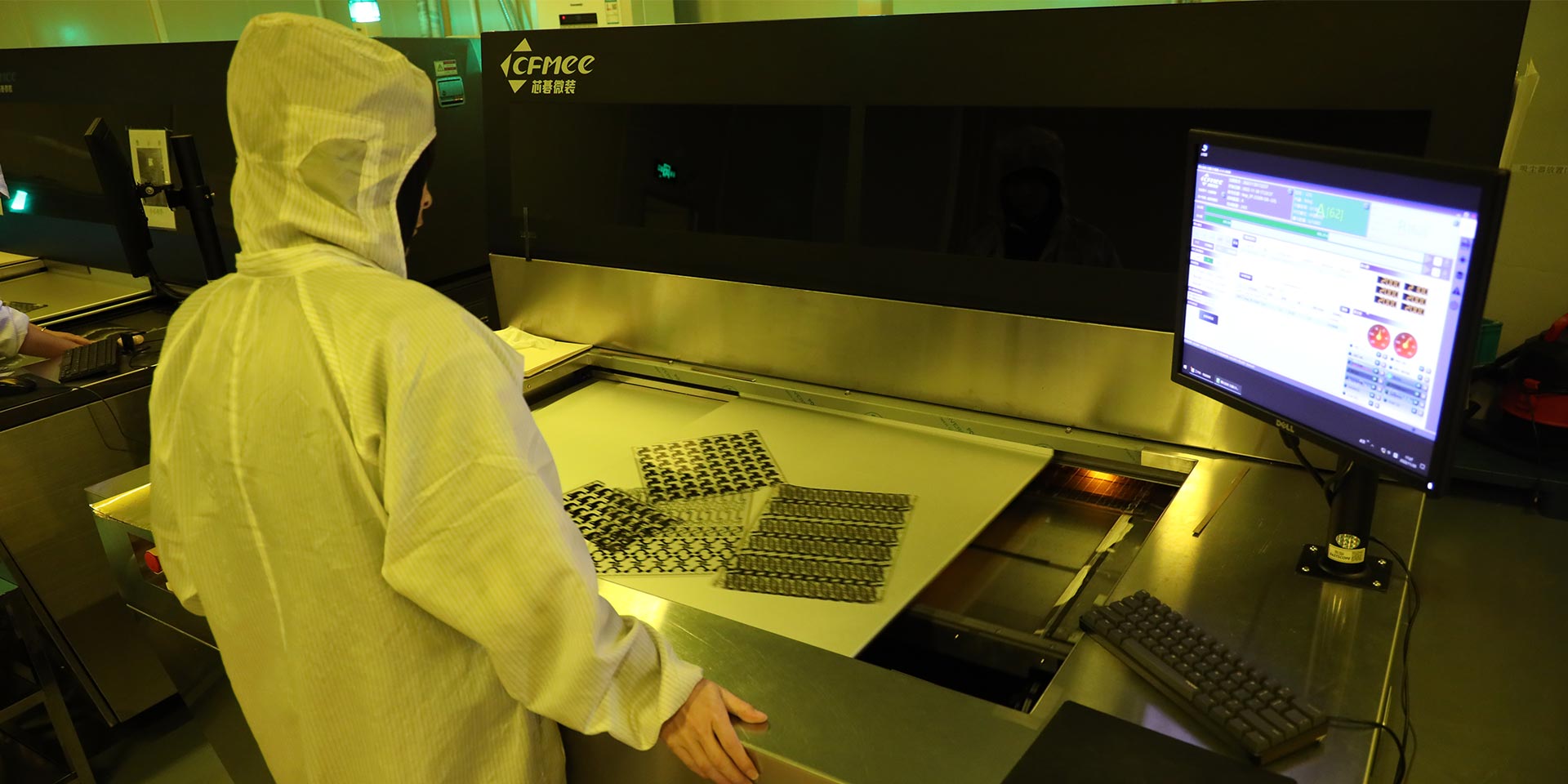

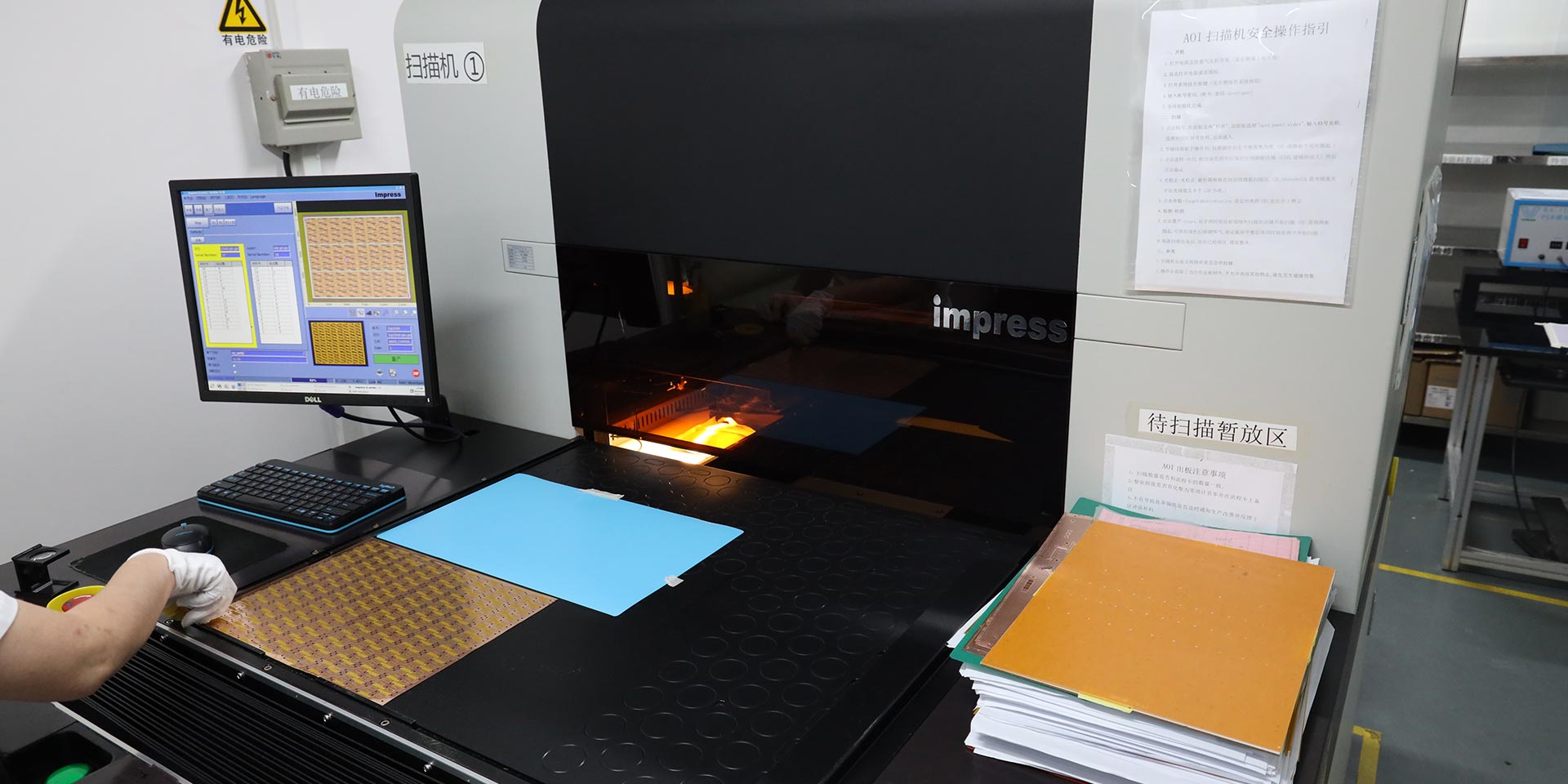

9. AOI:Binciken gani ta atomatik. Ta hanyar ka'idar tunani na gani, ana watsa hoton zuwa kayan aiki don sarrafawa, kuma idan aka kwatanta da bayanan da aka saita, an gano matsalolin budewa da gajeren layi na layi.

10. Laminci:Rufe da'irar tagulla tare da fim mai kariya na sama don hana iskar oxygenation ko gajeriyar kewayawa, kuma a lokaci guda aiki azaman rufi da lankwasa samfur.

11. Laminating CV:Latsa fim ɗin rufewa da aka riga aka lakafta da farantin da aka ƙarfafa a cikin gabaɗaya ta babban zafin jiki da matsa lamba.

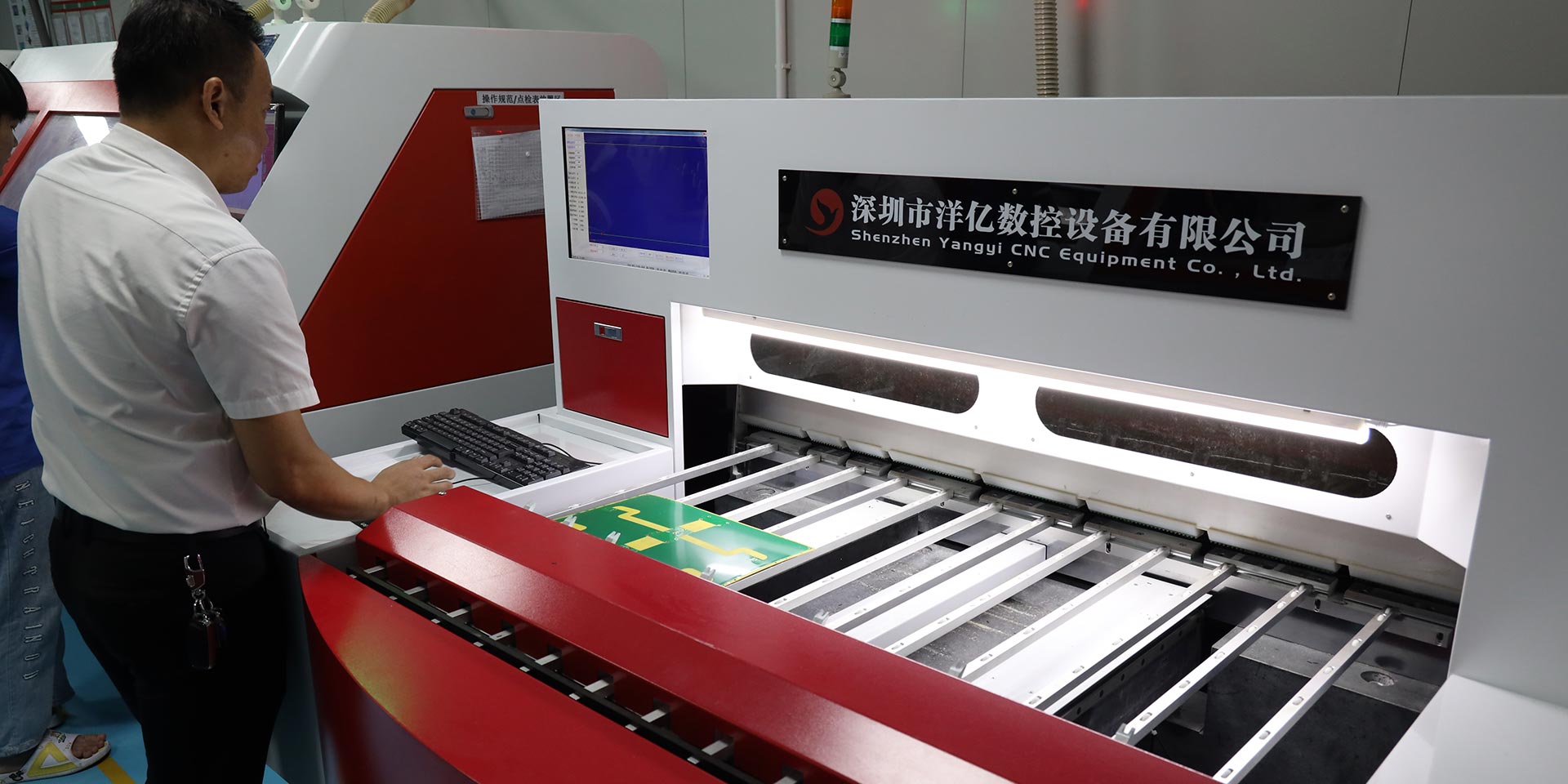

12. Buga:Yi amfani da ƙira da ƙarfin bugun inji don buga farantin aikin cikin girman jigilar kaya wanda ya dace da bukatun samarwa abokin ciniki.

13. Laminci(mafi girman allo na pcb rigid-flex)

14. Latsa:A ƙarƙashin yanayi mara amfani, samfurin yana zafi a hankali, kuma ana danna katako mai laushi da katako tare ta hanyar latsa mai zafi.

15. Hakowa ta biyu:Hana ramin da ke haɗa allo mai laushi da katako mai wuya.

16. Tsaftace Plasma:Yi amfani da plasma don cimma tasirin da hanyoyin tsaftacewa na al'ada ba za su iya cimma ba.

17. Narkar da tagulla (hard board):An sanya Layer na jan karfe a cikin rami don cimma nasarar gudanarwa.

18. Tagulla plating (hard board):Yi amfani da electroplating don kauri kaurin ramin jan ƙarfe da jan ƙarfe na saman.

19. Da'ira (busashen fim):Manna wani Layer na kayan daukar hoto a saman farantin da aka yi da jan karfe don zama fim don canja wurin tsari. Etching AOI Waya: Fitar da duk saman jan karfe banda tsarin kewayawa, fitar da tsarin da ake buƙata.

20. Solder mask (lallon siliki):Rufe duk layi da saman jan karfe don kare layin da rufewa.

21. Solder mask (bayyana):Tawada yana jurewa photopolymerization, kuma tawada a cikin wurin buga allo ya kasance a saman allon kuma yana ƙarfafawa.

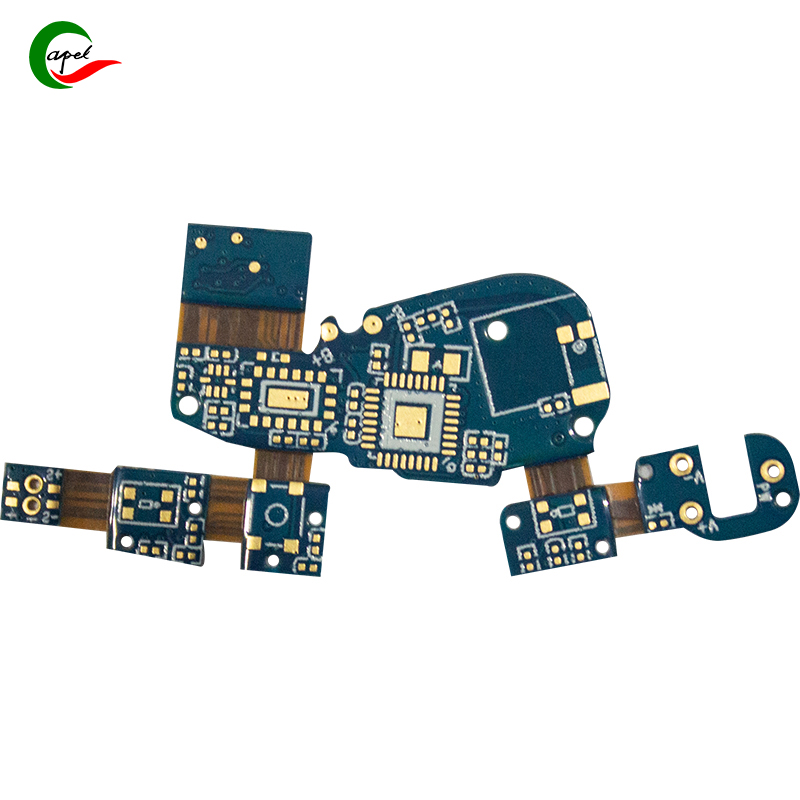

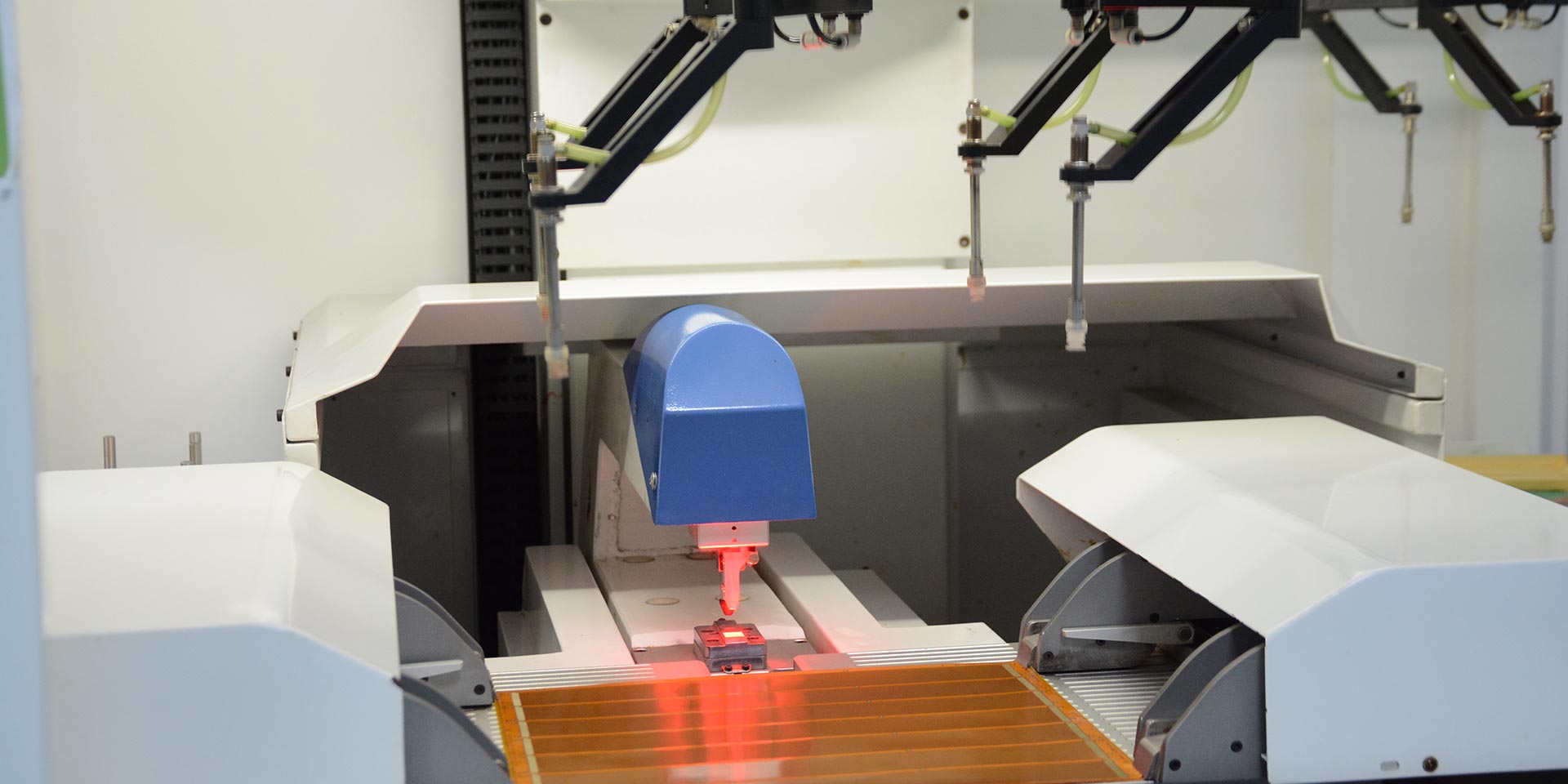

22. Ciwon Laser:Yi amfani da na'urar yankan Laser don aiwatar da takamaiman matakin yankan Laser akan matsayi na layukan junction mai ƙarfi, kwasfa sashin allo mai sassauƙa, da fallasa ɓangaren allo mai laushi.

23. Majalisa:Manna zanen gadon ƙarfe ko ƙarfafawa akan wuraren da suka dace na saman allo don haɗawa da haɓaka taurin mahimman sassa na FPC.

M pcb taro

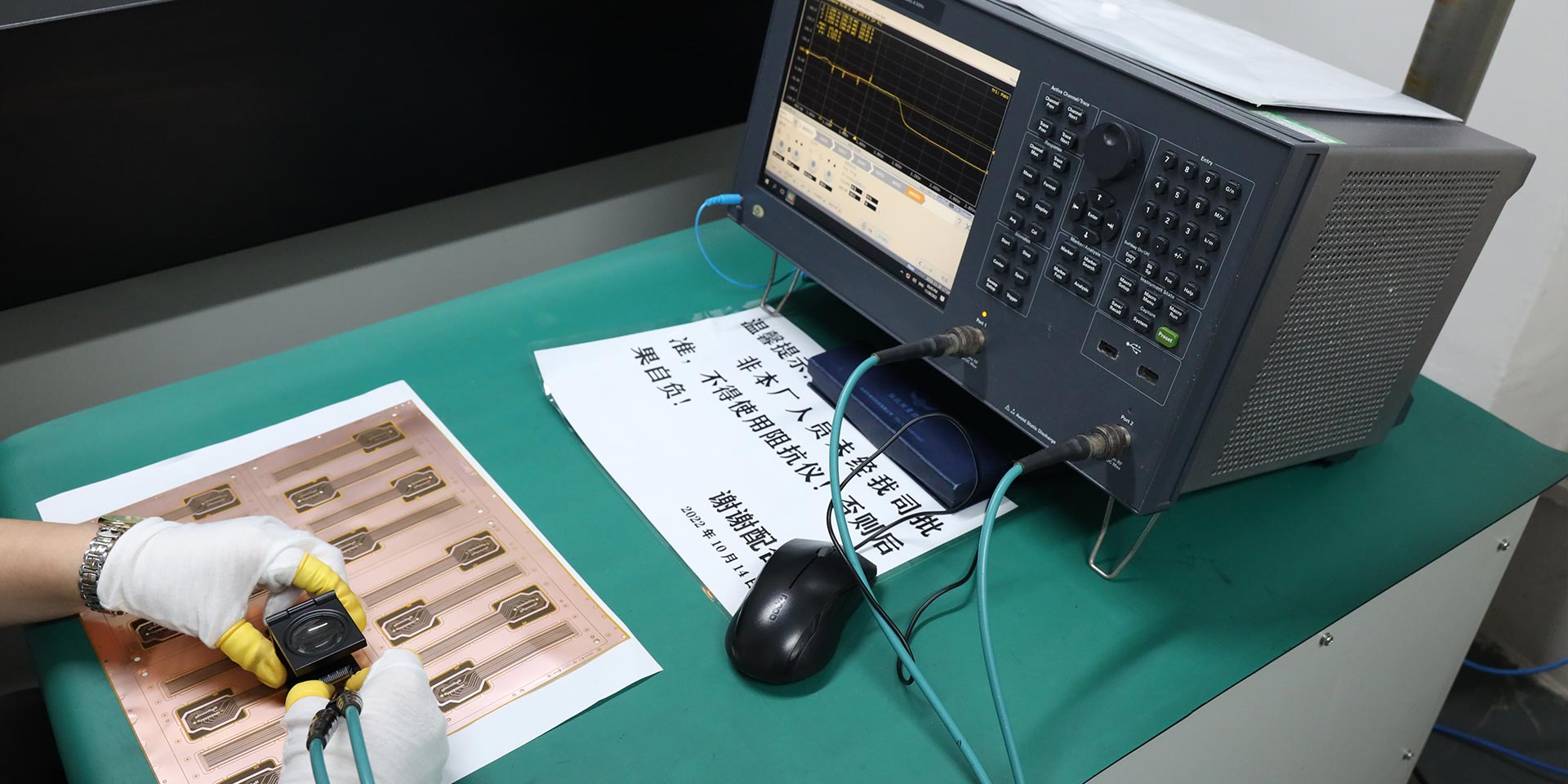

24. Gwaji:Yi amfani da bincike don gwada ko akwai buɗaɗɗe/gajeren lahani don tabbatar da aikin samfur.

25. Halaye:Buga alamomin alamar a kan allo don sauƙaƙe haɗuwa da gano samfuran da ke gaba.

26. Gong plate:Yi amfani da kayan aikin injin CNC don niƙa siffar da ake buƙata bisa ga buƙatun abokin ciniki.

27. FQC:Za a bincika samfuran da aka gama don bayyanar bisa ga buƙatun abokin ciniki, kuma za a zaɓi samfuran da ba su da lahani don tabbatar da ingancin samfur.

28. Marufi:Za a cika allunan da suka wuce cikakken dubawa bisa ga bukatun abokin ciniki kuma a aika su zuwa sito.

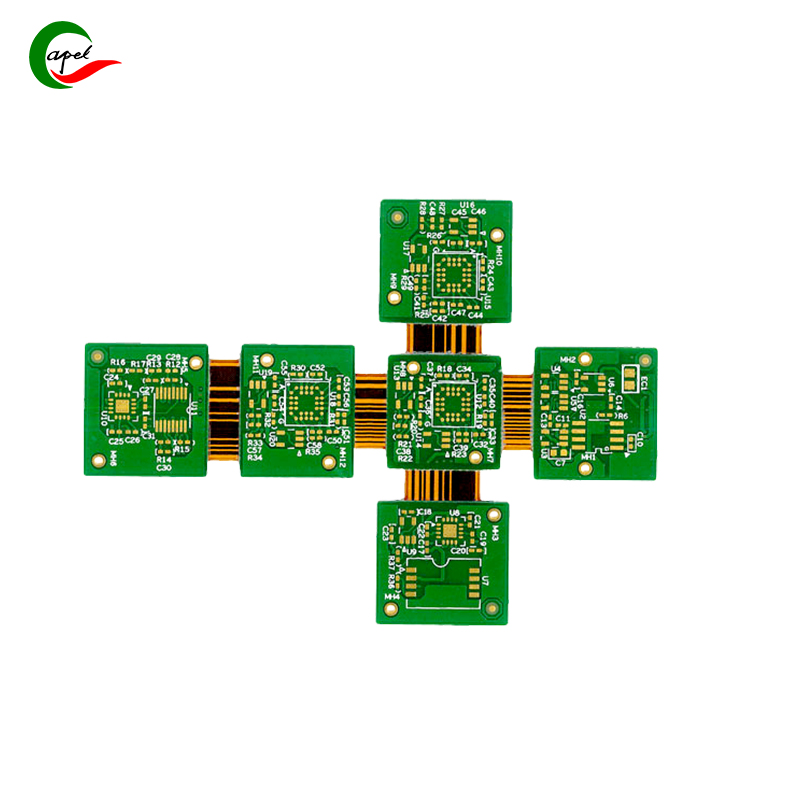

Turkiyya Rigid M PCB Majalisar

Bayar da gwaninta da taimako yayin lokacin ƙira, taimaka wa abokan ciniki haɓaka ƙirar su

don aiki, amintacce, da ingancin farashi;

Samun ikon samar da ƙananan ƙididdiga na samfuran PCB masu ƙarfi a cikin lokaci mai dacewa, ƙyale abokan ciniki don kimantawa da tabbatar da ƙirar su kafin a ci gaba da samarwa da yawa;

Kula da cikakkun bayanai a cikin tsarin taro, gami da takardar kudi na kayan (BOMs), umarnin taro, da bayanan gwaji;

Bayarwa kan lokaci (Capel yana da ingantaccen tsarin samarwa, ingantaccen sarrafa albarkatun ƙasa, da kusanci tare da abokan ciniki a cikin tsarin masana'antu.);

Magance duk wata damuwa ko al'amurra waɗanda zasu taso bayan bayarwa da bayar da goyan bayan fasaha na gaggawa ko sabis na garanti idan an buƙata.

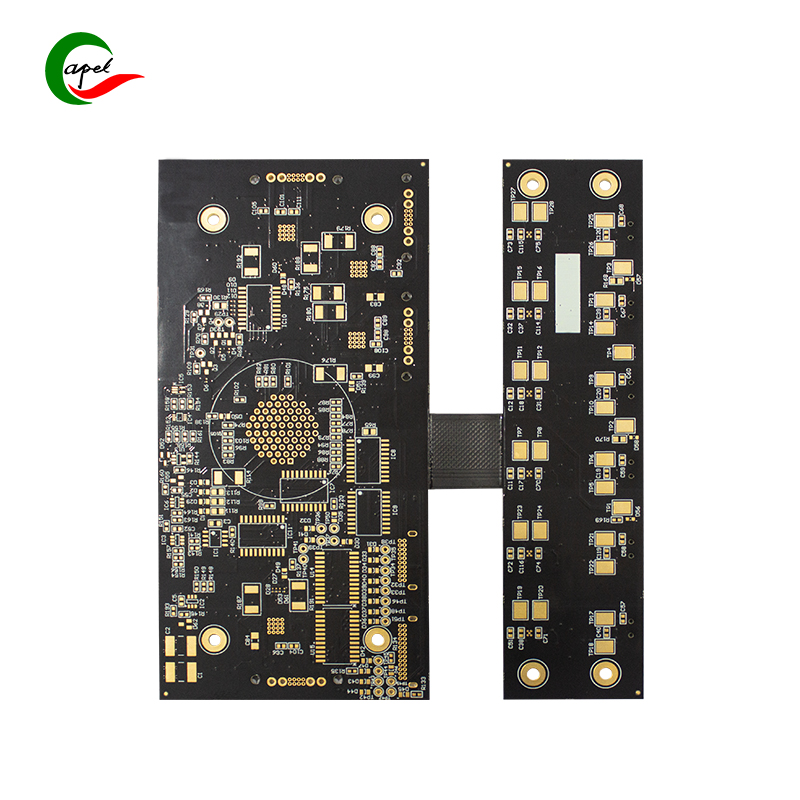

Fa'idodin Kera PCB Mai Sauƙi mai ƙarfi

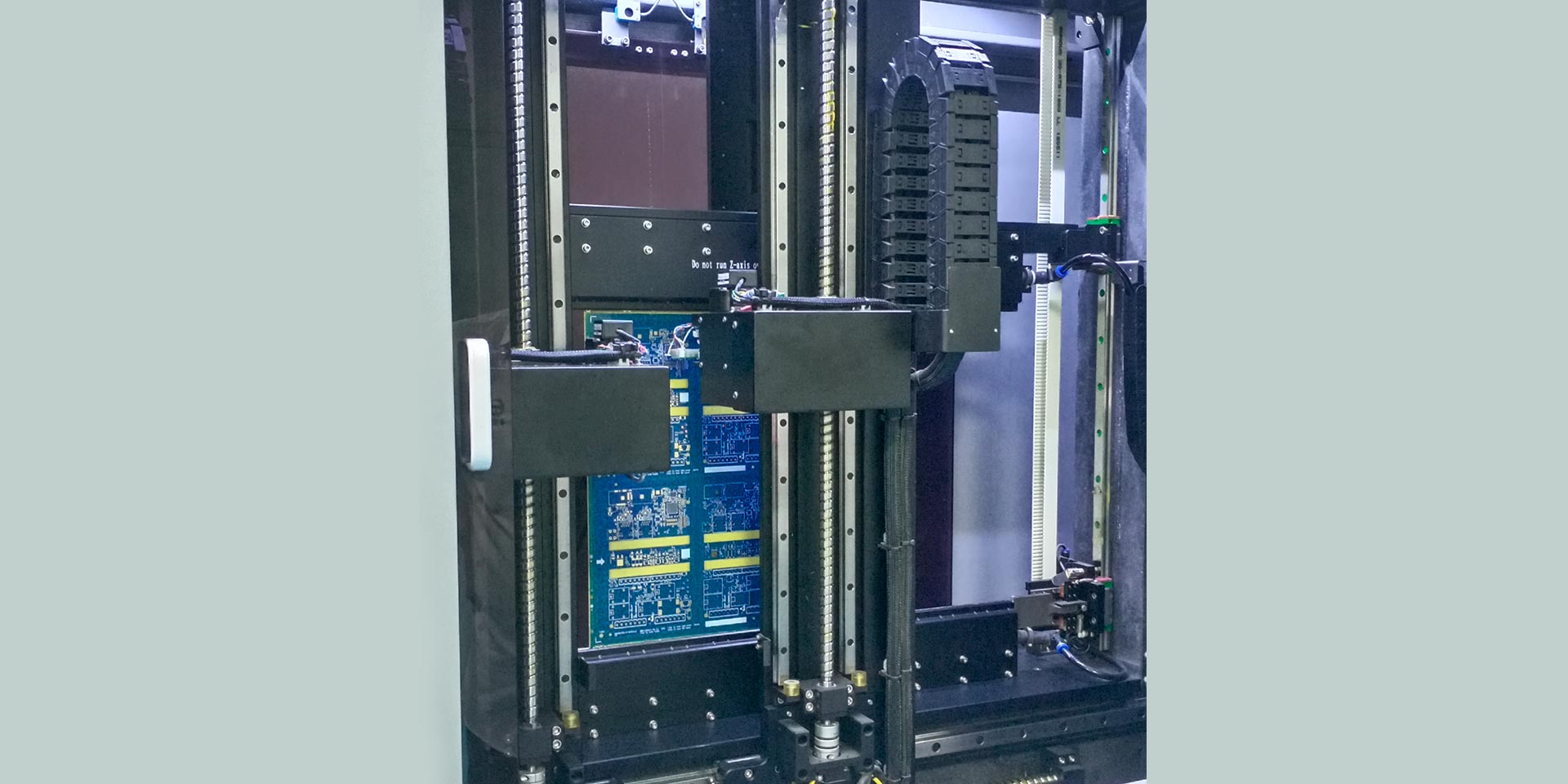

Cikakken sarrafa kansa da ingantaccen kayan samarwa

- Rage kurakurai na ɗan adam, haɓaka aiki, da haɓaka ƙimar gabaɗayan kwalayen da'irar mu mai sassauƙa.

Capel yana da tushe na R&D na kansa, masana'antar samarwa, da masana'antar faci don allon da'ira mai tsauri

-ci gaba da bincike da haɓakawa don ƙirƙirar sabbin hanyoyin warwarewa da haɓaka ayyukan samfuran abokan cinikinmu.

-Capel yana da cikakken iko akan tsarin masana'antu, yana tabbatar da kulawar inganci da ingantaccen samarwa, yana da gajeren lokacin jagora da isar da sauri.

-Capel na iya ɗaukar gyare-gyare da gyare-gyare zuwa ga allunan da'ira masu ƙarfi da suke samarwa, ba da tallafi bayan tallace-tallace da tabbatar da gamsuwar abokin ciniki.

Ci gaba da sabbin abubuwa na ingantacciyar fasahar tsari da ci gaba

-Mu prioritize bidi'a da m ci gaba a cikin m m PCB ƙirƙira tsari, ci gaba da bincike da kuma rungumi dabi'ar sababbin da kuma ci-gaba fasahar, samar muku da yankan-baki mafita da kuma tabbatar da cewa your m m PCBs alluna hadu da latest fasaha nagartacce.

-Haɓaka tsarin masana'anta don haɓaka inganci da rage farashi, rage sharar kayan abu, rage lokutan jagora, da ba da mafita mai inganci ga abokan cinikinmu.

Ƙarfin Samar da PCB mai sassauƙa

| Kashi | Iyawar Tsari | Kashi | Iyawar Tsari |

| Nau'in samarwa | Single Layer FPC m PCB FPC flec PCB Multilayer FPC Aluminum PCB Rigid-Flex PCB | Yadudduka Lamba | 1-30 yadudduka FPC M PCB 2-32 yadudduka Rigid-FlexPCB 1-60 yadudduka Rigid PCB HDI Alloli |

| Max Kerawa Girman | Single Layer FPC 4000mm Doublelayers FPC 1200mm Multi-Layer FPC 750mm M-Flex PCB 750mm | Insulating Layer Kauri | 27.5um / 37.5/ 50um / 65/75um 100um / 125um / 150um |

| Hukumar Kauri | Saukewa: FPC0.06mm-04mm M-Flex PCB025-60mm | Hakuri na Girman PTH | + 0.075 mm |

| Surface Gama | Immersion Zinariya/ nutsewa Zubar da Zinare /Tin Plating/OSP | Stiffener | FR4 /PI/ PET / SUS /PSA/Alu |

| Semi da'ira Girman Orifice | Min 0.4mm | Nisa Min Line Space | 0.045mm/0.045mm |

| Kauri Hakuri | + 0.03 mm | Impedance | 500-1200 |

| Takardun Tagulla Kauri | 9um/12um/18um/ 35um / 70um/100um | Impedance Sarrafa Hakuri | +10% |

| Hakuri ot Girman NPTH | + 0.05mm | Nisa Min Flush | 0.80mm |

| Min Via Hole | 0.1mm | aiwatarwa Daidaitawa | GB/IPC-650/PC-6012IPC-01311/ Saukewa: IPC-601311 |

| Takaddun shaida | Uland ROHS 5014001:2015 IS0 9001:2015 IATF16949:2016 | Halayen haƙƙin mallaka | samfurin haƙƙin mallaka ƙirƙira haƙƙin mallaka |

Gudanar da Inganci don Samar da PCB mai sauƙi mai ƙarfi

Cikakken tsarin kula da inganci

- Mun aiwatar da wani m ingancin kula da tsarin don tabbatar da mafi girma matsayi a m m PCB samar (kayan dubawa, tsari saka idanu, samfurin gwaji, da kuma kimantawa)

Ayyukanmu shine ISO 14001: 2015, ISO 9001: 2015, IATF16949: 2016 bokan

- sadaukarwarmu ga gudanarwa mai inganci, dorewar muhalli, da ci gaba da ingantawa, sadaukar da kai don isar da abin dogaro da inganci mai tsauri mai sassauƙa allo.

Samfuran mu UL da ROHS alama

- yana tabbatar da cewa PCBs masu sassaucin ra'ayi sun cika ka'idodin aminci kuma suna bin ka'idodin masana'antu, ba tare da abubuwa masu haɗari ba, sanya su abokantaka da muhalli da aminci don amfani a aikace-aikace daban-daban.

Sami fiye da 20 samfuran kayan amfani da haƙƙin mallaka da ƙirƙira

-mu mayar da hankali a kan tasowa na musamman da kuma m mafita a m m PCB masana'antu, Mu alƙawarin ga bidi'a tabbatar da cewa ka sami yankan-baki kayayyakin da hadu da takamaiman bukatun.

Mai Saurin Juya Rigid-Flex PCB Prototyping

24-hour mara tsayawa m m kewaye hukumar samar da sabis

Bayarwa don ƙananan oda yawanci yana ɗaukar kwanaki 5-7

Isar da taro yawanci yana ɗaukar kwanaki 10-15

| Production | Adadin yadudduka | Lokacin bayarwa (kwanakin kasuwanci) | |||

| Misali | Samar da Jama'a | ||||

| FPC | 1L | 3 | 6-7 | ||

| 2L | 4 | 7-8 | |||

| 3L | 5 | 8-10 | |||

| Don FPCs masu sassaucin ra'ayi tare da fiye da yadudduka 3, ƙara kwanakin kasuwanci 2 don kowane ƙarin Layer | |||||

| HDI binne makafi vias PCB da M-Flex PCB | 2-3L | 7 | 10-12 | ||

| 4-5L | 8 | 12-15 | |||

| 6L | 12 | 16-20 | |||

| 8L | 15 | 20-25 | |||

| 10-20L | 18 | 25-30 | |||

| SMT: Ƙara ƙarin kwanakin kasuwanci 1-2 zuwa lokacin bayarwa na sama | |||||

| RFQ: 2 aiki hours CS: 24 aiki hours | |||||

| EQ: 4 lokutan aiki Ƙarfin samarwa: 80000m / watan | |||||

Nan take Quote don PCB mai sassauƙa da Majalisar PCB Flex

Capel yana samarwa a cikin masana'anta kuma ƙungiyar ƙwararrun ƙwararrun ƙwararrun ƙwararrun shekaru 15 ke sarrafa su don tabbatar da cewa kowane samfurin ya cancanci 100%.