Mai Saurin Juyawa PCB Prototyping 6 Layer High-Density Multi-Layer M Sassaukan Allolin Don Motoci

Ƙayyadaddun bayanai

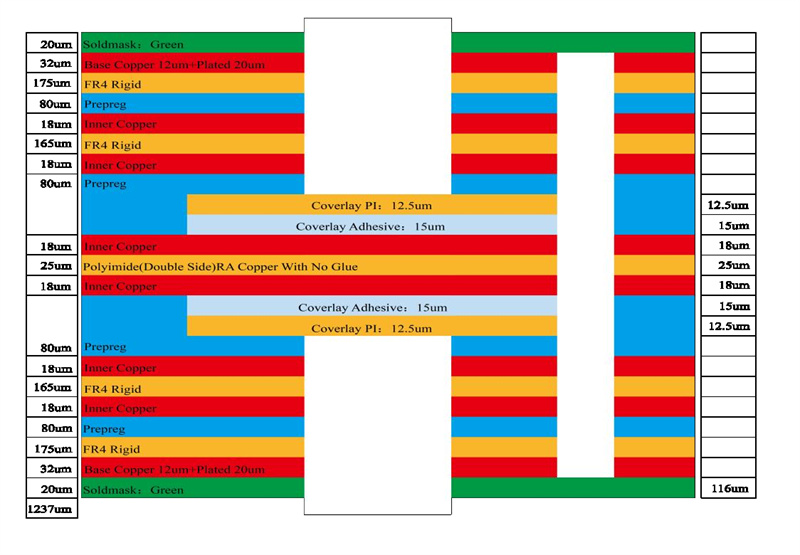

| Kashi | Iyawar Tsari | Kashi | Iyawar Tsari |

| Nau'in samarwa | FPC guda ɗaya / Layer Layer FPC Multi-Layer FPC / Aluminum PCBs PCBs masu ƙarfi-Flex | Lambar Layer | 1-16 yadudduka FPC 2-16 yadudduka Rigid-FlexPCB HDI Printed Allolin Da'ira |

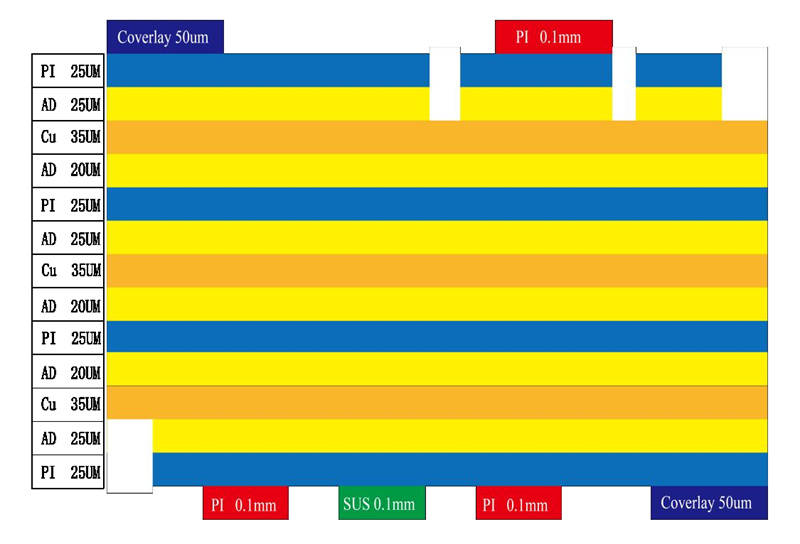

| Matsakaicin Girman Masana'anta | Single Layer FPC 4000mm Doulbe Layer FPC 1200mm Multi-Layer FPC 750mm M-Flex PCB 750mm | Insulating Layer Kauri | 27.5um / 37.5/ 50um / 65/ 75um / 100um / 125um / 150um |

| Kaurin allo | FPC 0.06mm - 0.4mm M-Flex PCB 0.25 - 6.0mm | Haƙuri na PTH Girman | ± 0.075mm |

| Ƙarshen Sama | Immersion Zinariya/ nutsewa Silver/Gold Plating/Tin Plat ing/OSP | Stiffener | FR4 / PI / PET / SUS / PSA / Alu |

| Girman Orifice Semicircle | Min 0.4mm | Min Line Space/ Nisa | 0.045mm/0.045mm |

| Hakuri mai kauri | ± 0.03mm | Impedance | 50Ω-120Ω |

| Kauri Na Karfe Copper | 9um/12um/18um/35um/70um/100um | Impedance Sarrafa Hakuri | ± 10% |

| Haƙuri na NPTH Girman | ± 0.05mm | Nisa Min Flush | 0.80mm |

| Min Via Hole | 0.1mm | Aiwatar da Daidaitawa | GB / IPC-650 / IPC-6012 / IPC-6013II / Saukewa: IPC-6013I |

Muna yin alluna masu sassauƙa da yawa tare da ƙwarewar shekaru 15 tare da ƙwarewar mu

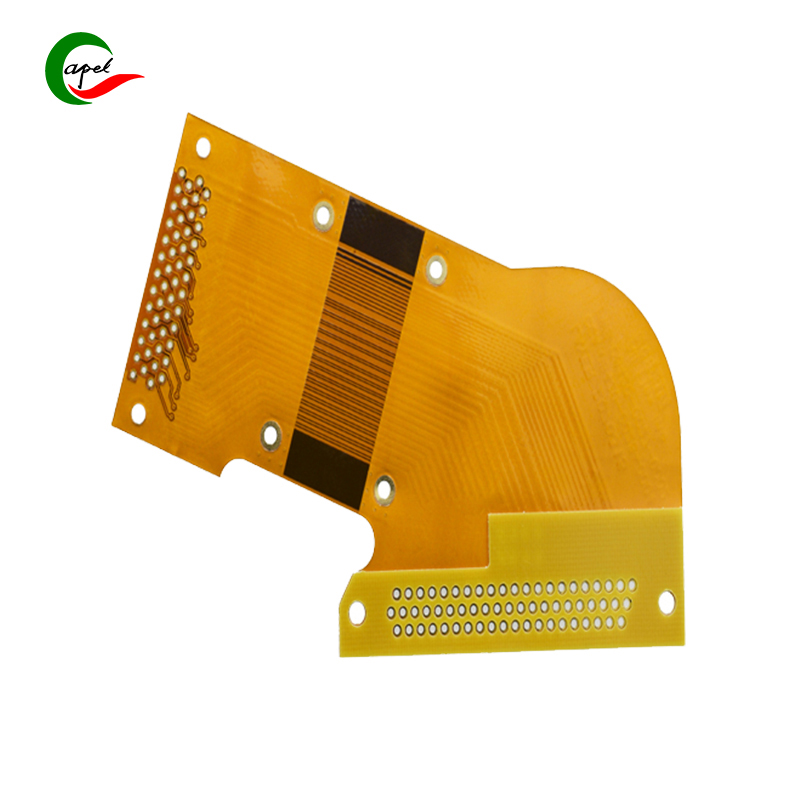

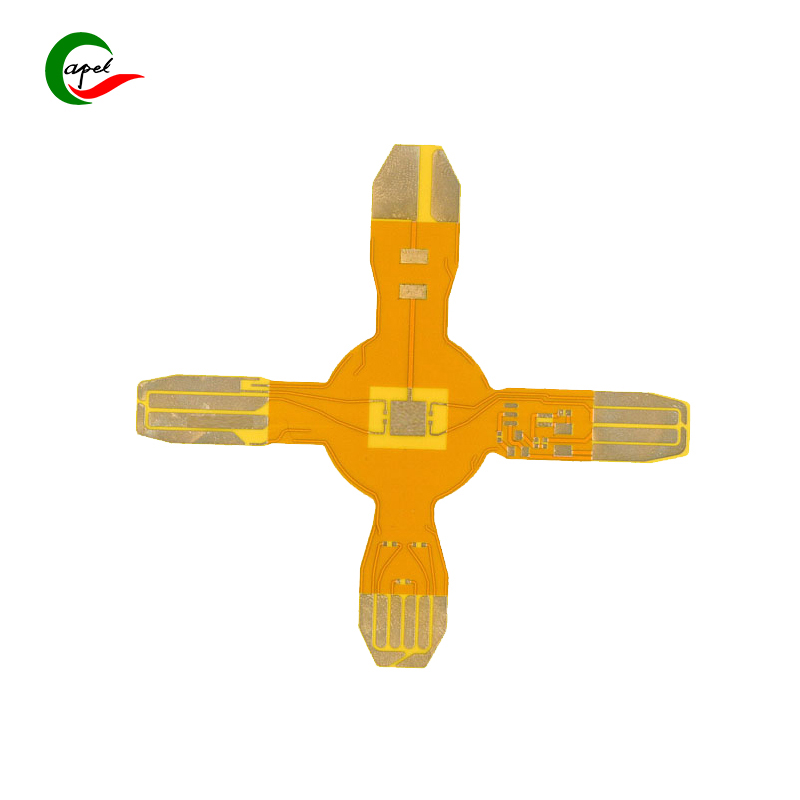

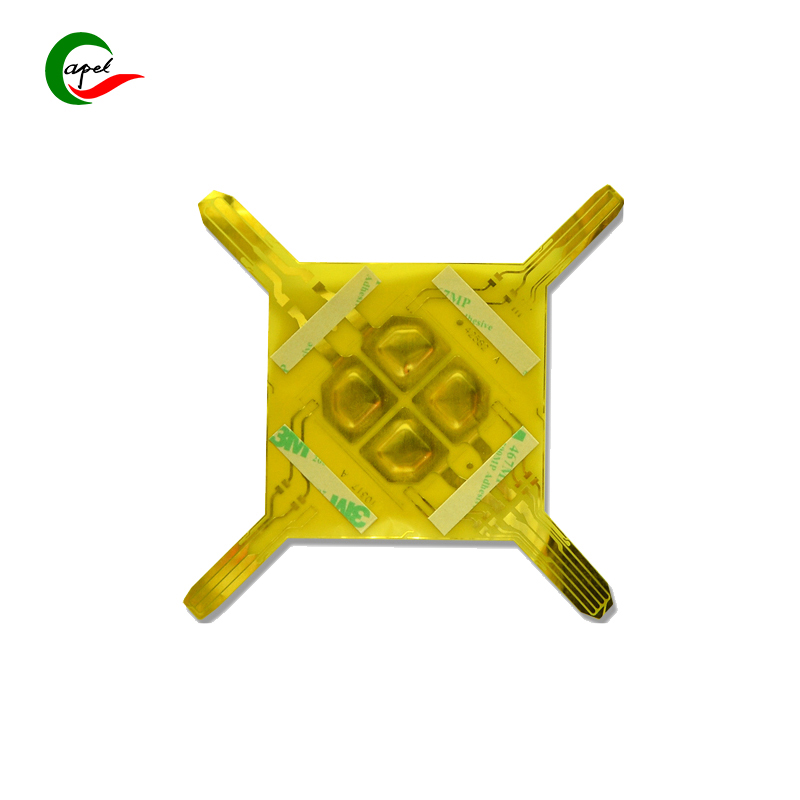

3 Layer Flex PCBs

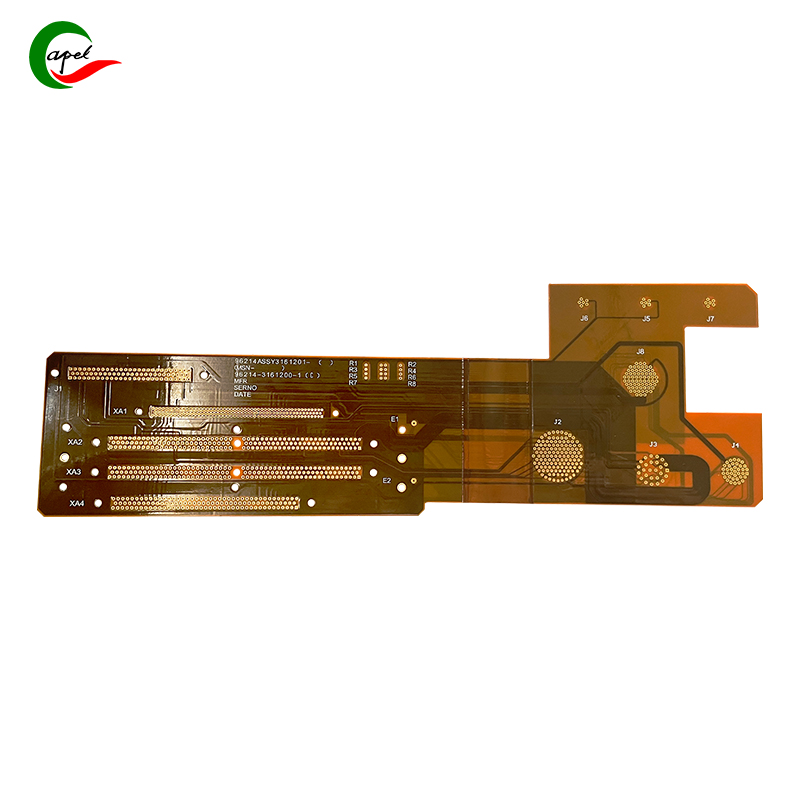

8 Layer Rigid-Flex PCBs

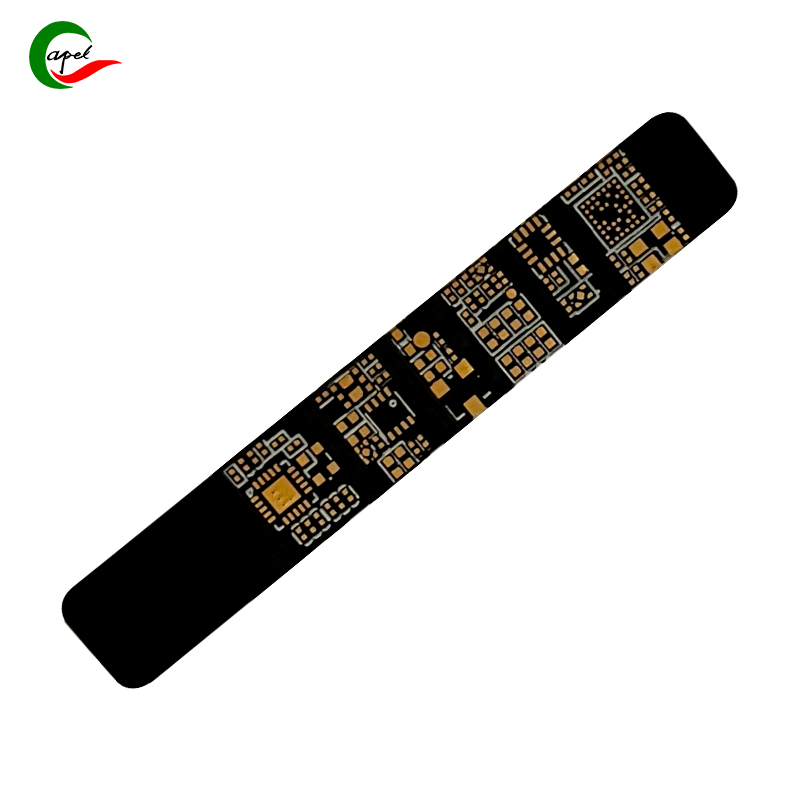

8 Layer HDI Buga Allolin da'ira

Gwaji da Kayan Aiki

Gwajin Microscope

Binciken AOI

Gwajin 2D

Gwajin Tashin hankali

Gwajin RoHS

Binciken Flying

Gwaji na kwance

Lankwasawa Teste

Sabis ɗin allo mai sassauƙan Layer ɗin mu da yawa

. Bayar da goyon bayan fasaha Pre-tallace-tallace da bayan-tallace-tallace;

. Custom har zuwa 40 yadudduka, 1-2days Saurin jujjuya abin dogaro da samfur, Sayen kayan aikin, Majalisar SMT;

. Yana ba da na'urar lafiya duka, Kula da Masana'antu, Motoci, Jirgin Sama, Lantarki na Mabukaci, IOT, UAV, Sadarwa da sauransu.

. Ƙungiyoyin injiniyoyinmu da masu bincike sun sadaukar da kai don cika bukatunku tare da daidaito da ƙwarewa.

Menene buƙatun fasaha na PCBs na kera motoci don alluna masu sassauƙa da yawa?

1. Dorewa: Motoci PCBs dole ne su iya jure yanayin aiki mai tsauri na abin hawa, gami da canjin yanayin zafi, girgiza, da danshi. Sun yi alkawarin rayuwa mai tsawo da kuma kyakkyawan kwanciyar hankali na inji.

2. Babban Maɗaukaki: Multi-Layer m PCB yana ba da damar ƙarin haɗin wutar lantarki da abubuwan haɗin gwiwa don haɗawa cikin ƙaramin sarari. Babban ƙira mai yawa yana ba da damar ingantacciyar hanya kuma yana rage girman PCB, yana adana sarari mai mahimmanci a cikin abin hawa.

3. Sassauci da lanƙwasa: PCBs masu sassauƙa na iya naɗawa cikin sauƙi, murɗawa ko lanƙwasa don dacewa da matsuguni ko daidaita surar mota. Ya kamata su kiyaye amincin wutar lantarki da injiniyoyi yayin maimaita lankwasawa da jujjuyawa.

4. Mutuncin sigina: Ya kamata a sami ƙarancin sigina ko tsangwama a cikin PCB don tabbatar da ingantaccen sadarwa tsakanin sassa daban-daban na lantarki. Yi amfani da dabaru kamar sarrafa impedance da ingantaccen ƙasa don kiyaye amincin sigina.

5. Thermal management: Automotive kewayawa allon yadda ya kamata ya watsar da zafi da aka haifar yayin aiki. Ingantattun dabarun sarrafa zafi, kamar yin amfani da ingantattun jiragen sama na jan karfe da ta hanyar zafi, suna da mahimmanci don hana zafi da tabbatar da ingantaccen aiki.

6. Kariyar EMI/RFI: Don hana tsangwama na lantarki (EMI) da tsangwama ta mitar rediyo (RFI), PCBs masu motoci suna buƙatar dabarun kariya masu kyau. Wannan ya ƙunshi amfani da garkuwa ko jiragen ƙasa don rage tasirin siginar lantarki na waje.

7. Gwajin kan layi: Tsarin PCB ya kamata ya sauƙaƙe gwaji da duba PCB ɗin da aka taru. Za a ba da damar isa ga wuraren gwaji da gwaje-gwaje don tabbatar da ingantaccen gwaji mai inganci yayin samarwa da kiyayewa.

8. Yarda da ka'idodin motoci: Ƙira da kera na PCBs na motoci suna buƙatar bin ka'idodin masana'antar kera motoci, kamar AEC-Q100 da ISO / TS 16949. Yarda da waɗannan ka'idodin yana tabbatar da amincin, aminci da ingancin PCBs.

Me yasa ake buƙatar Prototyping PCB mai sauri?

1. Sauri: Samfuran PCB mai sauri yana haɓaka hawan haɓakar samfur. Yana taimakawa rage lokacin da ake buƙata don maimaitawa, gwadawa, da haɓaka ƙirar PCB, yana ba injiniyoyi damar saduwa da ƙayyadaddun ƙayyadaddun ayyukan ko amsa da sauri ga buƙatun kasuwa.

2. Tabbatar da Zane: PCB Prototyping yana ba injiniyoyi damar tabbatar da ayyuka, aiki da kuma masana'anta na ƙirar PCB ɗin su kafin zuwa samarwa da yawa. Yana taimakawa ganowa da magance duk wani lahani na ƙira ko damar ingantawa, adana lokaci da kuɗi a cikin dogon lokaci.

3. Rage haɗari: Saurin samfurin PCB yana taimakawa rage haɗarin da ke tattare da samar da PCB mai yawa. Ta hanyar gwadawa da tabbatar da ƙira a cikin ƙananan batches, duk wani kuskuren kuskure ko batutuwa za a iya kama su da wuri, hana kurakurai masu tsada da sake yin aiki yayin ƙirar ƙira.

4. Cost ceto: Mai sauri PCB prototyping iya yin ingantaccen amfani da albarkatun da kayan. Ta hanyar kama al'amuran ƙira da wuri da yin gyare-gyare masu mahimmanci, injiniyoyi za su iya adana kayan da batattu da sake yin ƙira mai tsada.

5. Amincewar kasuwa: A cikin masana'antar da sauri, samun damar haɓakawa da sauri da ƙaddamar da sabbin kayayyaki na iya ba kamfani damar fa'ida. Samfurin PCB mai sauri yana bawa kamfanoni damar amsa buƙatun kasuwa da sauri, canza yanayin ko sabbin damammaki, tabbatar da fitowar samfur akan lokaci.

6. Keɓancewa da ƙididdigewa: Samfuran samfuri suna sauƙaƙe gyare-gyare da haɓakawa. Injiniyoyin na iya bincika sabbin dabarun ƙira, gwada fasali daban-daban, da gwaji tare da fasahar ci gaba. Yana ba su damar tura iyakoki da haɓaka samfuran yanke-yanke.