A cikin wannan shafin yanar gizon, za mu bincika daidaitattun kauri na PCBs masu ƙarfi da kuma dalilin da yasa yake da mahimmanci a cikin ƙirar lantarki.

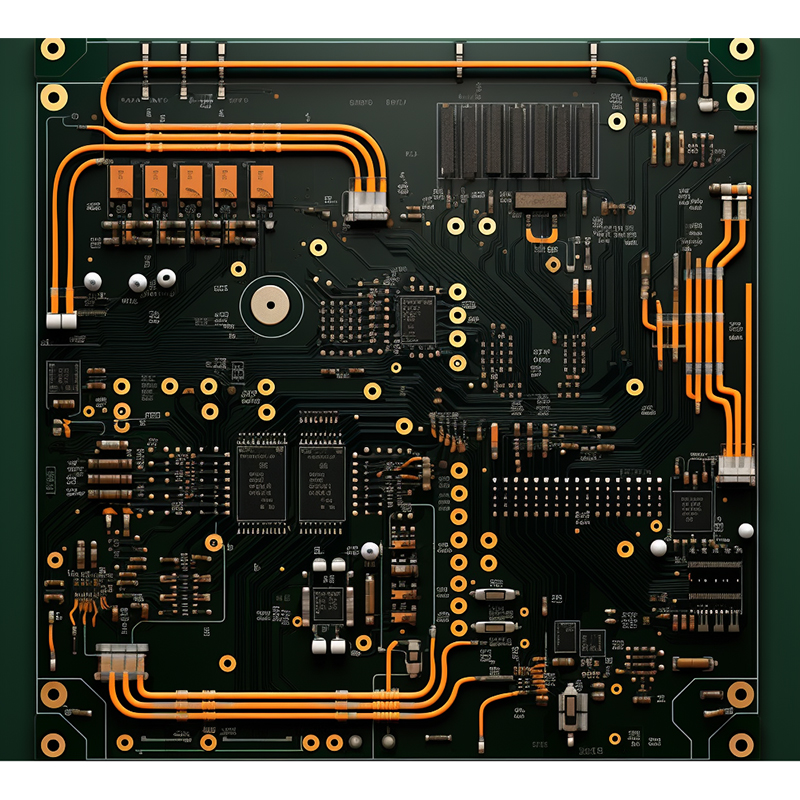

Buga allon kewayawa (PCBs) wani abu ne mai mahimmanci a cikin kayan lantarki na zamani. Suna samar da dandamali don hawa da haɗa kayan haɗin lantarki daban-daban. A tsawon shekaru, PCBs sun ci gaba da haɓakawa don saduwa da buƙatun ƙira masu rikitarwa da aikace-aikace iri-iri. Ɗayan irin wannan juyin halitta shine ƙaddamar da PCBs masu sassaucin ra'ayi, waɗanda ke ba da fa'idodi na musamman akan allon da'ira na gargajiya ko sassauƙa.

Kafin mu shiga cikin daidaitattun kauri, bari mu fara fahimtar menene rigid-flex.PCB mai sassauƙan sassauƙa ƙaƙƙarfan ƙayyadaddun da'irori masu sassauƙa da aka haɗa akan allo guda. Suna haɗa fa'idodin PCB masu ƙarfi da sassauƙa don samar da mafita iri-iri don aikace-aikacen da yawa. Waɗannan allunan sun ƙunshi nau'i-nau'i masu yawa na da'irori da aka haɗa su ta hanyar sassauƙan yadudduka, suna ba da ƙaƙƙarfan bayani abin dogaro ga kayan lantarki.

Yanzu, idan ana batun kauri mai ƙarfi-sauƙi, babu ƙayyadaddun kauri wanda ya shafi duk ƙira.Kauri na iya bambanta dangane da takamaiman buƙatun aikace-aikacen. Gabaɗaya magana, kauri na katako mai sassauƙa da ƙarfi ya bambanta daga 0.2mm zuwa 2.0mm. Koyaya, dole ne a yi la'akari da abubuwa daban-daban kafin tantance mafi kyawun kauri don ƙira ta musamman.

Babban abin da za a yi la'akari da shi shine buƙatun inji na PCB. Alƙalai masu tsattsauran ra'ayi suna da ingantacciyar sassauƙa da ƙarfin lanƙwasawa, amma kauri yana taka muhimmiyar rawa wajen tantance juzu'in hukumar gaba ɗaya.Allolin sirara sun fi zama masu sassauƙa da sauƙin lanƙwasa da dacewa cikin matsatsun wurare. A gefe guda, faranti masu kauri suna ba da mafi kyawun rigidity kuma suna iya jure matakan damuwa. Dole ne masu zanen kaya su daidaita ma'auni tsakanin sassauci da tsauri dangane da aikace-aikacen da aka yi niyya.

Wani abin da ke shafar kauri shine lamba da nau'in abubuwan da za a saka a kan allo. Wasu sassa na iya samun ƙuntatawa tsayi waɗanda ke buƙatar allon kewayawa mai kauri don ɗaukar su daidai.Hakazalika, jimlar nauyi da girman abubuwan da aka gyara zasu kuma shafi madaidaicin kauri na allon. Dole ne masu zanen kaya su tabbatar da cewa kauri da aka zaɓa na iya tallafawa nauyi da girman abubuwan haɗin da aka haɗa ba tare da shafar tsarin tsarin hukumar ba.

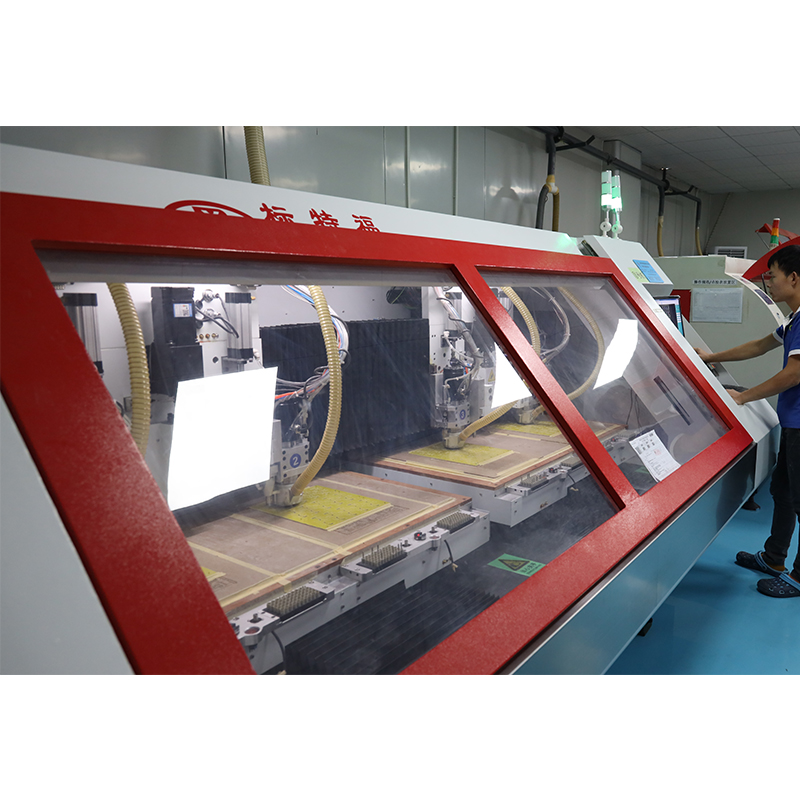

Bugu da kari, datafiyar matakai da fasahaAna amfani da su don samar da alluna masu tsattsauran ra'ayi kuma suna shafar daidaitaccen kauri.Ƙananan alluna gabaɗaya suna buƙatar ƙarin ingantattun fasahohin masana'antu kuma suna iya haɗawa da tsadar masana'anta. Sabili da haka, kauri da aka zaɓa ya kamata ya kasance daidai da iyawar tsarin ƙirar da aka zaɓa don tabbatar da ingantaccen aiki mai inganci da farashi.

A taƙaice, yayin da babu ƙayyadaddun ƙayyadaddun ƙayyadaddun ƙayyadaddun ƙayyadaddun ƙayyadaddun ƙayyadaddun ƙaƙƙarfan allo, yana da mahimmanci a yi la'akari da abubuwa da yawa yayin tantance mafi kyawun kauri don aikace-aikacen da aka bayar.Bukatun injina, lamba da nau'in abubuwan haɗin gwiwa, nauyi da ƙayyadaddun ƙima, da ƙarfin masana'anta duk suna taka muhimmiyar rawa a cikin wannan tsarin yanke shawara. Samun ma'auni daidai tsakanin sassauci, tsauri da aiki yana da mahimmanci don haɓaka aiki da amincin PCBs masu sassaucin ra'ayi.

A taƙaice, daidaitaccen kauri na alluna masu sassauƙa na iya bambanta dangane da takamaiman buƙatun aikace-aikacen.Dole ne masu zanen kaya su kimanta abubuwa a hankali kamar buƙatun injiniyoyi, iyakokin sassa da ƙarfin masana'anta don tantance mafi kyawun kauri don ƙirar su. Ta hanyar la'akari da waɗannan fannoni, masu zanen kaya za su iya tabbatar da cewa PCBs masu tsauri masu ƙarfi sun cika aikin da ake buƙata da ƙa'idodin dogaro yayin samar da sassauci da ayyuka masu dacewa.

Lokacin aikawa: Satumba 18-2023

Baya