bari mu shiga cikin tsarin masana'antu na sassauƙan da'irori kuma mu fahimci dalilin da yasa ake amfani da su sosai a masana'antu daban-daban.

Wuraren da'irori masu sassauƙa, kuma aka sani da sassauƙan da'irori masu sassauƙa ko FPCs, sun shahara a cikin masana'antu daban-daban. Daga na'urorin lantarki na mabukaci zuwa na'urorin kiwon lafiya, da'irori masu sassauƙa sun canza yadda aka kera kayan lantarki da kera su. Yayin da buƙatun na'urorin lantarki masu sauƙi da masu nauyi ke ci gaba da ƙaruwa, yana da mahimmanci a fahimci tsarin kera na'urorin sassauƙa da kuma yadda suka zama wani ɓangare na fasahar zamani.

Da'irori masu sassauƙa da gaske haɗe ne na yadudduka masu sassauƙa, irin su polyester ko polyimide, waɗanda aka ɗora alamomi, pads, da abubuwan haɗin gwiwa. Waɗannan da'irori suna da sassauƙa kuma ana iya naɗe su ko naɗe su, suna sa su dace don aikace-aikace inda sarari ya iyakance.

1. Zane-zane a cikin masana'anta mai sassauƙa:

Mataki na farko na kera da'ira mai sassauƙa shine tsarin ƙira da tsari. Injiniyoyi da masu zanen kaya suna aiki tare don ƙirƙirar shimfidu waɗanda suka dace da takamaiman buƙatun aikace-aikacen. Layout ɗin ya haɗa da jeri alamun gudanarwa, abubuwan haɗin gwiwa, da duk wani ƙarin fasalulluka waɗanda ƙila a buƙata.

2. Zaɓin kayan abu a cikin ƙirƙira da'ira mai sassauƙa:

Bayan tsarin ƙira, mataki na gaba shine zaɓar kayan da suka dace don kewayawa mai sassauƙa. Zaɓin kayan aiki ya dogara da dalilai kamar sassaucin da ake buƙata, zafin aiki, da kayan lantarki da injina da ake buƙata. Polyimide da polyester ana amfani da su da yawa saboda ingantaccen sassauci da kwanciyar hankali na thermal.

3. Samar da ma'aunin tushe a cikin yin kewaye:

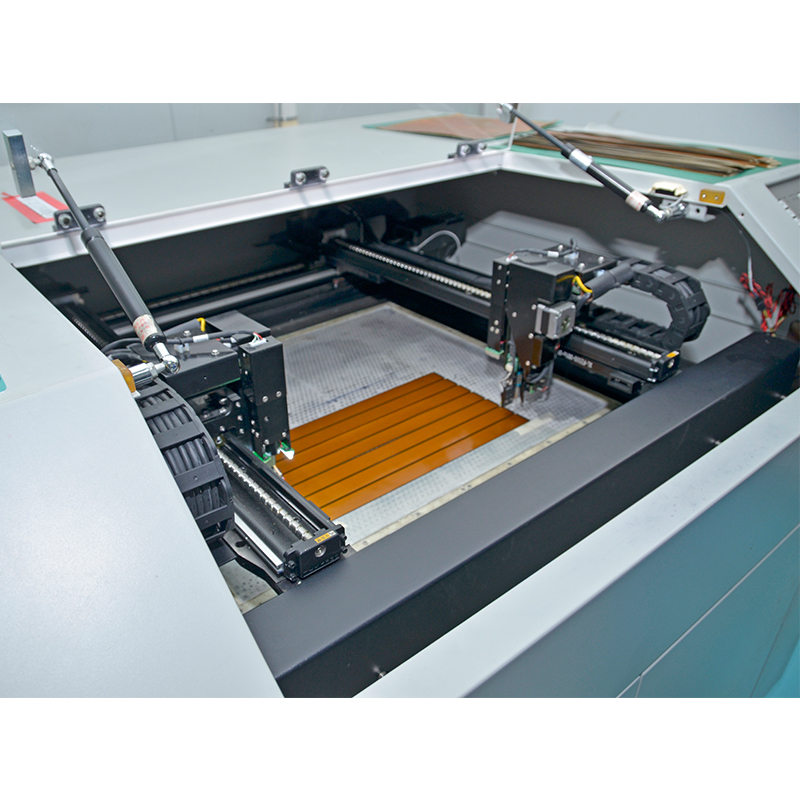

Da zarar an zaɓi kayan, ƙirƙira ƙirar tushe ta fara. Matsakaicin yawanci shine ƙaramin bakin ciki na polyimide ko fim ɗin polyester. Ana tsaftace kayan da aka yi amfani da shi, an lulluɓe shi da manne, kuma an lakafta shi da foil na jan ƙarfe. Kaurin foil na jan karfe da substrate na iya bambanta dangane da takamaiman bukatun aikace-aikacen.

4. Etching da laminating a flex circuit samarwa:

Bayan an gama aikin lamination, ana amfani da wani abu na sinadari don cire foil ɗin jan ƙarfe da ya wuce gona da iri, yana barin alamun da ake so. Sarrafa tsarin etching ta amfani da abin rufe fuska mai jurewa ko dabarun daukar hoto. Da zarar etching ya cika, ana tsabtace da'ira mai sassauƙa kuma an shirya shi don mataki na gaba na tsarin masana'anta.

5. Sassan taro a cikin masana'anta mai sassauƙa:

Bayan an gama aiwatar da etching, da'irar mai sassauƙa tana shirye don haɗakar abubuwa. Ana amfani da fasahar ɗorawa saman saman (SMT) don jeri sassa kamar yadda yake ba da dama daidai da haɗuwa ta atomatik. Aiwatar da manna mai siyar zuwa ga pads ɗin gudanarwa kuma yi amfani da injin ɗauka da wuri don sanya abubuwan haɗin gwiwa. Sa'an nan kuma za a yi zafi da kewaye, yana haifar da solder don manne da pads, rike da bangaren a wurin.

6. Gwaji da dubawa a cikin masana'anta masu sassauƙa:

Da zarar tsarin taro ya cika, ana gwada da'irar sassauƙa sosai kuma an duba shi. Gwajin wutar lantarki yana tabbatar da cewa alamomi da abubuwan haɗin gwiwa suna aiki kamar yadda aka zata. Hakanan ana iya yin ƙarin gwaje-gwaje, kamar hawan keke na zafin jiki da gwajin damuwa na inji, don kimanta dorewa da amincin da'irori masu sassauƙa. Duk wani lahani ko batutuwa da aka samu yayin gwaji ana gano su kuma an gyara su.

7. M ɗaukar hoto da karewa a cikin masana'anta masu sassauƙa:

Don kare da'irori masu sassauƙa daga abubuwan muhalli da damuwa na inji, ana amfani da sutura masu sassauƙa ko yadudduka masu kariya. Wannan Layer na iya zama abin rufe fuska na solder, abin rufe fuska, ko haɗin duka biyun. Rufin yana haɓaka ƙarfin juzu'i na flex kuma yana haɓaka rayuwar sabis.

8. Dubawa na ƙarshe da marufi a cikin masana'anta mai sassauƙa:

Bayan da'irar flex ta bi duk hanyoyin da suka dace, ana gudanar da bincike na ƙarshe don tabbatar da ya dace da ƙayyadaddun da ake buƙata. Ana tattara madaukai masu sassauƙa a hankali don kare su daga lalacewa yayin jigilar kaya da ajiya.

A taƙaice, tsarin kera na da'irori masu sassauƙa ya ƙunshi matakai masu rikitarwa da yawa, gami da ƙira, zaɓin kayan aiki, ƙira, haɗawa, gwaji, da kariya.Yin amfani da fasaha na zamani da kayan haɓakawa yana tabbatar da cewa madaukai masu sassauƙa sun cika buƙatun da ake buƙata na masana'antu daban-daban. Tare da sassaucin ra'ayi da ƙayyadaddun ƙira, masu sassauƙa masu sassauƙa sun zama muhimmin ɓangare na haɓaka sabbin na'urorin lantarki na zamani. Daga wayoyin komai da ruwanka zuwa na'urorin likitanci, da'irori masu sassauƙa suna canza yadda ake haɗa kayan aikin lantarki cikin rayuwarmu ta yau da kullun.

Lokacin aikawa: Satumba-21-2023

Baya