A cikin duniyar dijital ta yau mai sauri, buƙatun na'urorin lantarki masu ƙarfi, ƙarami da ƙarfi na ci gaba da haɓaka. Don biyan waɗannan buƙatun, masana'antun na'urorin lantarki sun gabatar da babban haɗin haɗin kai (HDI) fasaha na PCB mai sassauƙa.Idan aka kwatanta da PCBs masu sassaucin ra'ayi na gargajiya,HDI masu sassaucin ra'ayi PCBsbayar da mafi girman sassauƙar ƙira, ingantaccen aiki, da ingantaccen abin dogaro. A cikin wannan labarin, za mu bincika menene HDI masu sassaucin ra'ayi PCBs, fa'idodin su, da yadda suka bambanta da PCBs masu sassaucin ra'ayi na gargajiya.

1. Fahimtar HDI Flex PCB:

HDI m PCB, wanda kuma aka sani da high-density interconnect m buga kewaye allon, shi ne m kewaye da ke ba da babban da'irar yawa da ba da damar hadaddun da kuma

miniaturized kayayyaki. Ya haɗu da fa'idodin PCB masu sassauƙa, waɗanda aka sani don ikon su na lanƙwasa da daidaita su zuwa siffofi daban-daban, tare da fasahar haɗin kai mai girma zuwa

hanya ƙarin alamun kewayawa a cikin ƙaramin sarari.

1.2 Ta yaya ake yin HDI m PCB?

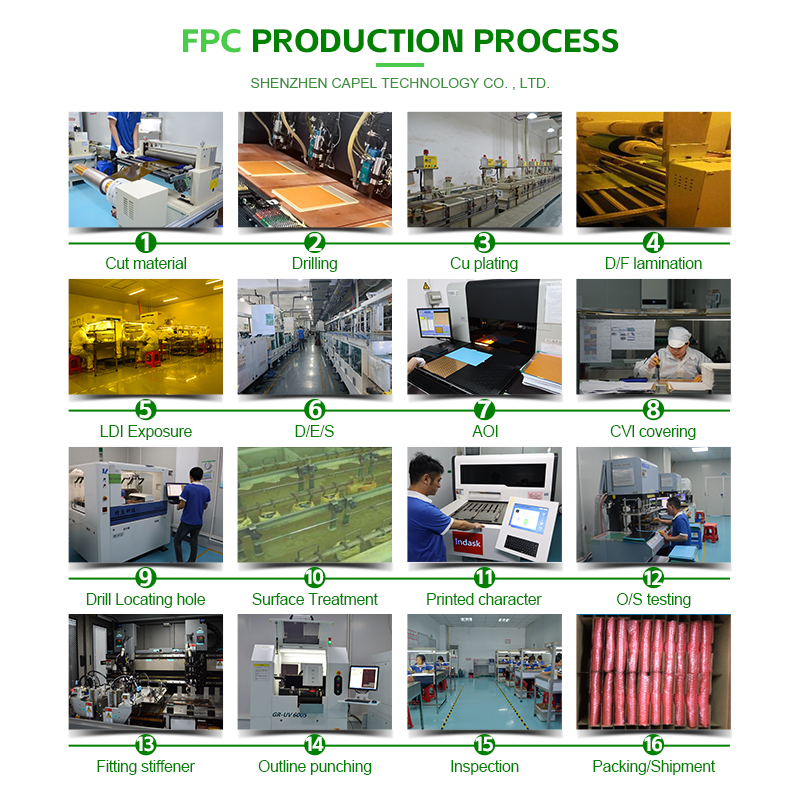

Tsarin masana'antu na HDI m PCBya ƙunshi matakai masu mahimmanci da yawa:

Zane:

Mataki na farko shine tsara shimfidar da'ira, la'akari da girman, siffa da tsari na abubuwan da ake buƙata da aikin da ake so.

Shirye-shiryen kayan aiki:

Zaɓi ku shirya kayan da ake buƙata don PCBs masu sassauƙa, kamar foil na jan karfe, adhesives, da kayan sassauƙan sassauƙa.

Tarin Layer:

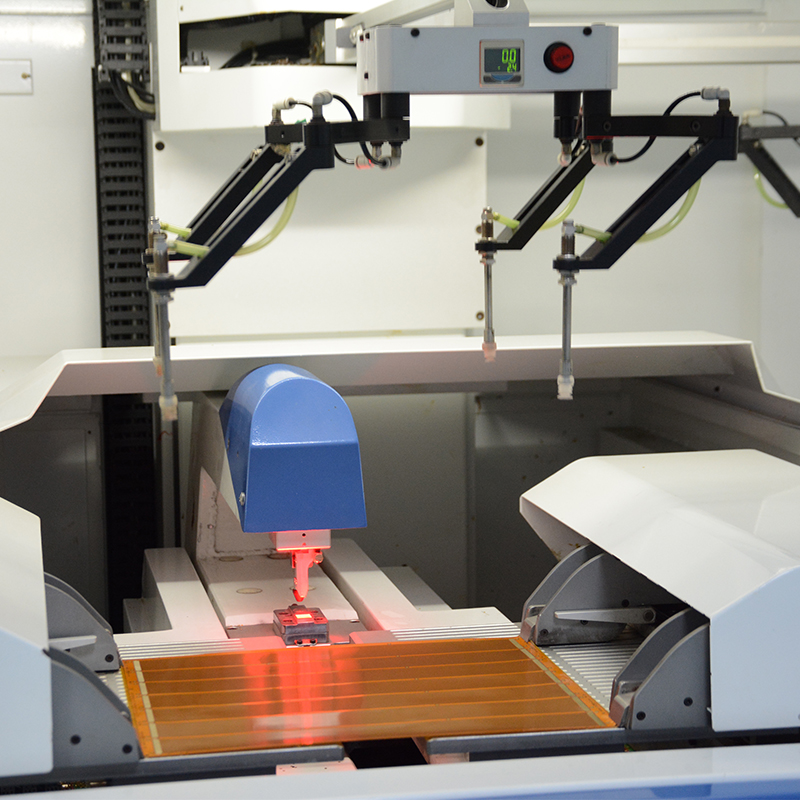

Yadudduka da yawa na kayan sassauƙa, foil ɗin tagulla, da adhesives ana tara su tare don samar da tushen kewayawa. Laser Drilling: Ana amfani da hakowa Laser don ƙirƙirar ƙananan ramuka ko tayoyin da ke haɗa yadudduka daban-daban na kewaye. Wannan yana ba da damar yin wayoyi a cikin matsatsun wurare.

Rufe Copper:

Ramukan da aka kafa ta hanyar hakowa Laser ana lullube su da tagulla don tabbatar da haɗin wutar lantarki tsakanin yadudduka daban-daban.

Etching Circuit:

Tagulla mara amfani yana gogewa, yana barin alamun da'irar da ake so.

Aikace-aikacen Maskin Solder:

Ana amfani da abin rufe fuska don kare da'irori da hana gajerun da'irori yayin taro.

Hawan sashi:

Abubuwan da aka haɗa kamar haɗaɗɗun da'irori, resistors, da capacitors ana ɗora su akan PCB mai sassauƙa ta amfani da fasahar ɗorawa saman (SMT) ko wasu hanyoyin da suka dace.

An gwada kuma an duba:

An kammala HDI masu sassaucin ra'ayi PCBs an gwada su sosai kuma an bincika su don tabbatar da ingantaccen aiki da inganci.

1.3 Amfanin PCB mai sassauƙa na HDI:

Fa'idodin HDI m PCB Idan aka kwatanta da PCB na gargajiya, HDI m PCB yana da fa'idodi da yawa, gami da:

Ƙara yawan da'ira:

Fasahar HDI tana ba da damar ɗimbin kewayawa mafi girma, yana ba da damar ƙarin abubuwan da za a sanya su cikin ƙaramin sawun. Wannan yana haifar da ƙaramin ƙira da ƙima.

Ingantattun sigina:

Gajerun tazarar kewayawa a cikin HDI flex PCBs yana haifar da ƙarancin tsangwama na lantarki (EMI), yana haifar da ingantacciyar siginar sigina, rage karkatar da sigina da tabbatar da ingantaccen aiki.

Ingantattun Amincewa:

Idan aka kwatanta da PCBs masu sassaucin ra'ayi na gargajiya, HDI masu sassaucin ra'ayi PCBs suna da ƴan abubuwan damuwa kuma sun fi juriya ga girgiza, lankwasawa, da damuwa na thermal. Wannan yana inganta cikakken aminci da rayuwar da'irar.

Samfuran ƙira:

Fasahar HDI tana ba da damar ƙirar da'ira mai rikitarwa, tana ba da damar haɗa nau'ikan yadudduka da yawa, makafi da binne ta hanyar, abubuwan da suka dace, da saurin sigina mai sauri.

Adana farashi:

Duk da rikitarwa da ƙarancinsa, HDI masu sassaucin ra'ayi PCBs na iya adana farashi ta hanyar rage girman gabaɗaya da nauyin samfurin ƙarshe, yana sa su zama masu inganci don aikace-aikacen da sarari da nauyi ke da mahimmanci.

2.Comparison na HDI m PCB da gargajiya m PCB:

2.1 Bambance-bambancen asali a cikin tsari:

Babban bambanci tsakanin ainihin tsarin HDI m PCB da na gargajiya m PCB ta'allaka ne a cikin kewaye yawa da kuma amfani da interconnection fasahar.

PCBs masu sassaucin ra'ayi na gargajiya yawanci sun ƙunshi nau'i ɗaya na kayan sassauƙa kamar polyimide, tare da alamun jan ƙarfe a saman. Waɗannan alluna yawanci suna da ƙayyadaddun ƙarancin kewayawa saboda ƙarancin yadudduka masu yawa da hadaddun haɗin kai.

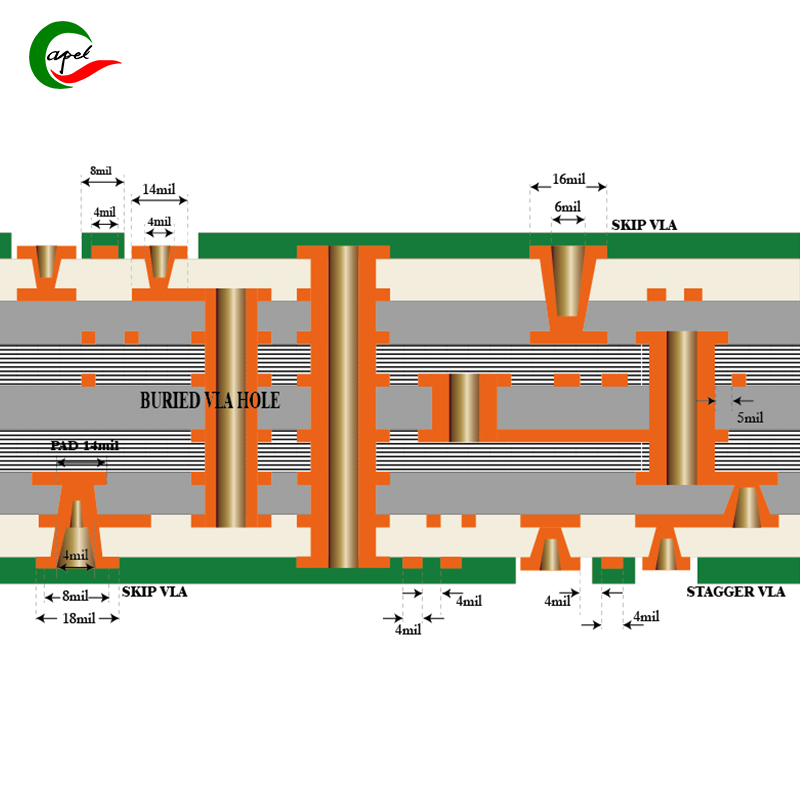

A gefe guda, HDI mai sassauƙa na PCB yana ɗaukar fasahar haɗin kai mai girma, wanda zai iya sarrafa ƙarin alamun da'ira a cikin ƙaramin sarari. Ana samun wannan ta amfani da yadudduka masu sassauƙa da yawa waɗanda aka jera su tare da alamun tagulla da adhesives. HDI masu sassaucin ra'ayi na PCB yawanci suna amfani da makafi da binne ta hanyar, waɗanda ramuka ne da aka haƙa ta takamaiman yadudduka don haɗa alamun da'ira a cikin jirgi, don haka inganta ƙarfin tuƙi gabaɗaya.

Bugu da ƙari, HDI masu sassaucin ra'ayi na PCBs na iya amfani da microvias, waɗanda ƙananan ramuka ne waɗanda ke ba da damar rarrabuwa mai yawa. Amfani da microvias da sauran fasahar haɗin kai na ci gaba na iya ƙara haɓaka da'ira sosai idan aka kwatanta da PCBs masu sassauƙa na gargajiya.

2.2 Babban ci gaba na HDI m PCB:

HDI masu sassaucin ra'ayi PCBs sun sami babban ci gaba da ci gaba cikin shekaru. Wasu manyan ci gaban da aka samu a fasahar PCB masu sassauƙa ta HDI sun haɗa da:

Miniaturization:

Fasahar HDI tana ba da damar ƙarancin na'urorin lantarki ta hanyar ƙyale ƙarin alamun kewayawa a cikin ƙasan sarari. Wannan yana buɗe hanya don haɓaka ƙanana, ƙaƙƙarfan samfura kamar wayoyin hannu, na'urorin da za a iya sawa da kayan aikin likita.

Ƙara yawan da'ira:

Idan aka kwatanta da PCBs masu sassauƙa na gargajiya, amfani da yadudduka da yawa, makafi da aka binne vias, da microvias a cikin PCBs masu sassaucin ra'ayi na HDI yana ƙaruwa da yawa. Wannan yana ba da damar haɗa ƙarin hadaddun ƙirar kewayawa da ci gaba a cikin ƙaramin yanki.

Mafi girman gudu da amincin sigina:

HDI masu sassaucin ra'ayi PCBs na iya tallafawa sigina masu sauri da haɓaka ƙimar sigina yayin da nisa tsakanin abubuwan haɗin gwiwa da haɗin haɗin gwiwa ke raguwa. Wannan ya sa su dace da aikace-aikacen da ke buƙatar amintaccen watsa siginar, kamar tsarin sadarwa mai tsayi ko kayan aiki mai ƙarfi da bayanai.

Shirye-shiryen abubuwan da suka dace:

Fasahar HDI tana sauƙaƙe shimfidar abubuwan da aka gyara masu kyau, wanda ke nufin za a iya sanya abubuwan haɗin gwiwa kusa da juna, yana haifar da ƙara ƙaranci da ƙima na shimfidar da'ira. Wuraren ɓangarorin ƙaƙƙarfan ƙaƙƙarfan wuri yana da mahimmanci ga ci-gaba aikace-aikacen da ke buƙatar manyan ayyuka na lantarki.

Ingantattun kula da thermal:

HDI masu sassaucin ra'ayi PCBs suna da ingantattun damar sarrafa zafin rana saboda amfani da yadudduka da yawa da kuma ƙarar wuri don zubar da zafi. Wannan yana ba da damar ingantaccen kulawa da

sanyaya manyan kayan aikin wuta, yana tabbatar da mafi girman aikin su.

2.3 Aiki da kwatancen aiki:

Lokacin kwatanta ayyuka da aikin HDI masu sassaucin ra'ayi PCBs zuwa PCBs masu sassaucin ra'ayi na gargajiya, akwai abubuwa da yawa da za a yi la'akari da su:

Yawan Wuta:

Idan aka kwatanta da PCBs masu sassaucin ra'ayi na gargajiya, HDI masu sassaucin ra'ayi PCBs suna ba da mafi girman girman kewaye. Fasahar HDI na iya haɗa nau'i-nau'i da yawa, ta hanyar makafi, binne vias, da microvias, yana ba da damar ƙarin ƙira da ƙira mai yawa.

Mutuncin Sigina:

Rage tazarar da ke tsakanin sawu da amfani da ingantattun dabarun haɗin kai a cikin HDI flex PCBs yana haɓaka amincin sigina. Wannan yana nufin mafi kyawun watsa sigina da ƙananan murdiya idan aka kwatanta da PCBs masu sassauƙa na al'ada.

Sauri da bandwidth:

HDI masu sassaucin ra'ayi PCBs suna iya tallafawa sigina mafi girma saboda ingantaccen siginar siginar da rage tsangwama na lantarki. PCBs masu sassaucin ra'ayi na al'ada na iya samun iyakancewa dangane da saurin watsa sigina da bandwidth, musamman a aikace-aikacen da ke buƙatar ƙimar ƙimar bayanai.

Samfuran ƙira:

Idan aka kwatanta da PCBs masu sassaucin ra'ayi na gargajiya, HDI masu sassaucin ra'ayi PCBs suna ba da mafi girman sassaucin ƙira. Ƙarfin haɗa nau'i-nau'i masu yawa, makafi da binne vias, da microvias suna ba da damar ƙarin hadaddun ƙirar kewaye. Wannan sassauci yana da mahimmanci musamman ga aikace-aikacen da ke buƙatar ƙaƙƙarfan ƙira ko kuma suna da ƙayyadaddun ƙuntatawa na sarari.

Farashin:

HDI masu sassaucin ra'ayi PCBs sun kasance sun fi tsada fiye da PCBs masu sassaucin ra'ayi na gargajiya saboda haɓakar haɓaka da dabarun haɗin kai da ke ciki. Koyaya, ƙaramar haɓakawa da haɓaka aikin da HDI masu sassaucin ra'ayi PCBs ke bayarwa na iya sau da yawa ba da tabbacin ƙarin farashin lokacin da aka yi la'akari da ƙimar ƙimar ƙarshe.

2.4 Abubuwan dogaro da Dorewa:

Dogaro da dorewa abubuwa ne masu mahimmanci ga kowane na'ura ko tsarin lantarki. Abubuwa da yawa sun shigo cikin wasa yayin kwatanta dogaro da dorewar HDI masu sassaucin ra'ayi PCBs zuwa PCBs masu sassaucin ra'ayi na gargajiya:

Sassaucin injina:

Dukansu HDI da PCBs masu sassaucin ra'ayi na gargajiya suna ba da sassaucin injina, yana ba su damar daidaitawa zuwa siffofi daban-daban da lanƙwasa ba tare da karye ba. Koyaya, HDI masu sassaucin ra'ayi PCBs na iya samun ƙarin ƙarfafa tsarin, kamar ƙarin yadudduka ko haƙarƙari, don tallafawa ƙarar da'ira. Wannan ƙarfafawa yana haɓaka cikakken aminci da dorewar HDI mai sassaucin ra'ayi PCB.

Anti-vibration da girgiza:

Idan aka kwatanta da PCB mai sassauƙa na gargajiya, HDI m PCB na iya samun ingantacciyar anti-vibration da ƙarfin girgiza. Yin amfani da makafi, binne, da microvias a cikin allunan HDI yana taimakawa wajen rarraba damuwa a ko'ina, rage yiwuwar lalacewa ko gazawar kewayawa saboda damuwa na inji.

Gudanar da thermal:

Idan aka kwatanta da PCB masu sassaucin ra'ayi na gargajiya, HDI flex PCB yana da yadudduka da yawa da yanki mafi girma, wanda zai iya samar da ingantaccen sarrafa zafi. Wannan yana inganta ɓarna zafi kuma yana taimakawa haɓaka gabaɗayan aminci da tsawon rayuwar na'urorin lantarki.

Tsawon Rayuwa:

Dukansu HDI da PCBs masu sassaucin ra'ayi na gargajiya na iya samun tsawon rayuwa idan an tsara su da ƙera su yadda ya kamata. Koyaya, haɓakar da'ira da dabarun haɗin kai na ci gaba da ake amfani da su a cikin PCBs masu sassaucin ra'ayi na HDI suna buƙatar yin la'akari da hankali na abubuwa kamar damuwa mai zafi, dacewa da kayan aiki, da gwajin dogaro don tabbatar da aiki na dogon lokaci.

Abubuwan muhalli:

HDI masu sassaucin ra'ayi PCBs, kamar PCBs masu sassaucin ra'ayi na gargajiya, suna buƙatar ƙira da ƙira don jure abubuwan muhalli kamar zafi, canjin zafin jiki, da fallasa ga sinadarai. HDI masu sassaucin ra'ayi PCBs na iya buƙatar ƙarin murfin kariya ko ɗaukar hoto don tabbatar da juriya ga yanayin muhalli.

HDI masu sassaucin ra'ayi PCBs suna ba da fa'idodi da yawa akan PCBs masu sassaucin ra'ayi na gargajiya dangane da girman kewaye, amincin sigina, sassaucin ƙira, da dogaro. Amfani da ci-gabafasahohin haɗin kai da fasaha na ƙaranci suna sa HDI masu sassaucin ra'ayi na PCB su dace da aikace-aikacen da ke buƙatar babban aiki na lantarki a cikin ƙaramin tsari.Koyaya, waɗannan fa'idodin sun zo a farashi mafi girma kuma takamaiman buƙatun aikace-aikacen yakamata a yi la'akari da su a hankali don sanin fasahar PCB mafi dacewa.

3.Amfanin HDI M PCB:

HDI (High Density Interconnect) masu sassaucin ra'ayi PCBs suna samun karbuwa a masana'antar lantarki saboda fa'idodi da yawa akan PCBs masu sassaucin ra'ayi na gargajiya.

3.1 Miniaturization da haɓaka sarari:

Miniaturization da haɓaka sararin samaniya: Ɗaya daga cikin manyan fa'idodin HDI m PCB shine ƙaranci da haɓaka sararin samaniya na kayan lantarki.Yin amfani da fasahar haɗin kai mai girma yana ba da damar ƙarin alamun kewayawa a cikin ƙaramin sarari. Wannan kuma yana sauƙaƙe haɓaka ƙananan ƙananan na'urorin lantarki. Ana amfani da HDI masu sassaucin ra'ayi PCBs a aikace-aikace kamar wayowin komai da ruwan, Allunan, wearables, da na'urorin likitanci inda sarari ya iyakance kuma ƙaramin girman yana da mahimmanci.

3.2 Inganta amincin sigina:

Inganta amincin sigina: Mutuncin sigina muhimmin abu ne a cikin kayan aikin lantarki, musamman a cikin aikace-aikacen sauri da sauri.HDI masu sassaucin ra'ayi PCBs sun yi fice wajen isar da ingantaccen sigina saboda raguwar tazara tsakanin abubuwan haɗin gwiwa da haɗin kai. Fasahar haɗin kai na ci gaba da ake amfani da su a cikin PCBs masu sassaucin ra'ayi na HDI, kamar makafi ta hanyar makafi, binne vias, da microvias, na iya rage asarar sigina da tsangwama na lantarki. Ingantattun siginar siginar yana tabbatar da ingantaccen watsa sigina kuma yana rage haɗarin kurakuran bayanai, yin HDI flex PCBs dacewa da aikace-aikacen da suka haɗa da watsa bayanai masu sauri da tsarin sadarwa.

3.3 Ingantaccen rarraba wutar lantarki:

Ingantattun Rarraba Wutar Lantarki: Wani fa'idar HDI flex PCB shine ikonsa na haɓaka rarraba wutar lantarki.Tare da haɓaka haɓakar na'urorin lantarki da buƙatar buƙatun wutar lantarki mafi girma, HDI flex PCBs suna ba da kyakkyawan bayani don ingantaccen rarraba wutar lantarki. Yin amfani da yadudduka da yawa da dabarun sarrafa wutar lantarki na ci gaba yana ba da damar mafi kyawun rarraba wutar lantarki mai faɗi, rage asarar wutar lantarki da raguwar wutar lantarki. Ingantattun rarraba wutar lantarki yana ba da damar ingantaccen aiki na kayan aikin yunwar wutar lantarki kuma yana rage haɗarin zafi, tabbatar da aminci da ingantaccen aiki.

3.4 Maɗaukakin ɓangarori mafi girma:

Maɗaukakin ɓangarori mafi girma: Idan aka kwatanta da PCB mai sassauƙa na gargajiya, HDI m PCB na iya cimma mafi girman girman ɓangaren.Amfani da na'urori masu yawa da fasahar haɗin kai na ci gaba suna ba da damar haɗa ƙarin kayan lantarki a cikin ƙaramin sarari. HDI masu sassaucin ra'ayi PCBs na iya ɗaukar hadaddun ƙira mai yawa da ƙira, wanda ke da mahimmanci ga aikace-aikacen ci-gaba waɗanda ke buƙatar ƙarin ayyuka da aiki ba tare da lalata girman allo ba. Tare da mafi girman yawan abubuwan ɓangarorin, masana'antun na iya ƙira da haɓaka samfuran lantarki mai sarƙaƙƙiya da fasali.

3.5 Inganta zubar zafi:

Ingantaccen zafi mai zafi: Rashin zafi yana da mahimmanci na ƙirar na'urar lantarki, kamar yadda zafi mai yawa zai iya haifar da lalacewar aiki, gazawar sassan har ma da lalacewar tsarin.Idan aka kwatanta da PCB mai sassauƙa na gargajiya, HDI m PCB yana da mafi kyawun aikin watsar zafi. Yin amfani da yadudduka da yawa da kuma ƙara yawan sararin samaniya yana ba da damar yin amfani da zafi mafi kyau, yadda ya kamata cirewa da kuma watsar da zafi da aka haifar da abubuwan da ke da wutar lantarki. Wannan yana tabbatar da ingantaccen aiki da amincin na'urorin lantarki, musamman a aikace-aikace inda sarrafa zafin jiki ke da mahimmanci.

HDI flex PCBs suna da fa'idodi da yawa waɗanda ke sa su zama kyakkyawan zaɓi don kayan lantarki na zamani. Ƙarfin su na ƙaranci da haɓaka sararin samaniya yana sa su dace don aikace-aikace inda ƙananan girman ke da mahimmanci. Ingantacciyar siginar siginar yana tabbatar da ingantaccen watsa bayanai, yayin da ingantaccen rarraba wutar lantarki yana ba da damar ingantaccen ƙarfin abubuwan haɗin gwiwa. HDI flex PCB's babba bangaren yawa yana ɗaukar ƙarin ayyuka da fasali, yayin da ingantattun ɓarkewar zafi yana tabbatar da kyakkyawan aiki da tsawon rayuwar na'urorin lantarki. Tare da waɗannan fa'idodin, HDI masu sassaucin ra'ayi PCBs sun zama larura a cikin masana'antu daban-daban kamar na'urorin lantarki, telecom, motoci, da kayan aikin likita.

4.Aikace-aikace na HDI m PCB:

HDI m PCB yana da fadi da kewayon aikace-aikace a daban-daban masana'antu. Ƙwararrun ƙarancin su, ingantaccen siginar siginar, haɓaka rarraba wutar lantarki, haɓaka mafi girma, da kuma inganta yanayin zafi ya sa su dace da kayan lantarki na mabukaci, na'urorin likitanci, masana'antar kera motoci, sararin samaniya da tsarin tsaro, da Intanet na Abubuwa da wearables. muhimmin sashi a cikin na'urar. HDI flex PCBs yana bawa masana'antun damar ƙirƙirar ƙananan na'urorin lantarki masu inganci don biyan buƙatun waɗannan masana'antu.

4.1 Lantarki na Masu amfani:

HDI m PCB yana da kewayon aikace-aikace a cikin masana'antar lantarki na mabukaci.Tare da ci gaba da buƙatar ƙarami, sirara, da ƙarin na'urori masu fa'ida, HDI flex PCBs yana bawa masana'antun damar biyan waɗannan buƙatun. Ana amfani da su a cikin wayoyin hannu, kwamfutar hannu, kwamfutar tafi-da-gidanka, smartwatch da sauran na'urorin lantarki masu ɗaukar hoto. Ƙarfin ƙaramin ƙarfi na HDI m PCBs yana ba da damar haɗin ayyuka da yawa a cikin ƙaramin sarari, yana ba da damar haɓaka na'urorin lantarki masu salo da inganci.

4.2 Na'urorin lafiya:

Masana'antar na'urorin likitanci sun dogara sosai akan HDI masu sassaucin ra'ayi PCBs saboda amincin su, sassauci, da ƙaramin tsari.Abubuwan lantarki a cikin na'urorin likitanci kamar na'urorin bugun zuciya, na'urorin ji, masu lura da glucose na jini da na'urorin hoto suna buƙatar cikakken daidaito. HDI masu sassaucin ra'ayi PCBs na iya biyan waɗannan buƙatun ta hanyar samar da haɗin kai mai girma da ingantaccen sigina. Bugu da ƙari, sassaucin su zai iya zama mafi kyawun haɗawa cikin na'urorin likitanci masu sawa don jin daɗin haƙuri da jin daɗi.

4.3 Masana'antar Motoci:

HDI masu sassaucin ra'ayi PCBs sun zama wani muhimmin sashi na motocin zamani.Masana'antar kera motoci na buƙatar manyan ayyuka na lantarki waɗanda za su iya jure yanayin ƙalubale da sadar da ingantattun ayyuka. HDI masu sassaucin ra'ayi PCBs suna ba da ingantaccen aminci, dorewa da haɓaka sararin samaniya don aikace-aikacen mota. Ana amfani da su a cikin tsarin kera motoci daban-daban ciki har da tsarin infotainment, tsarin kewayawa, na'urorin sarrafa wutar lantarki da tsarin taimakon direba na ci gaba (ADAS). HDI masu sassaucin ra'ayi PCBs na iya jure canjin zafin jiki, girgizawa da damuwa na inji, yana mai da su dacewa da mugun yanayi na kera motoci.

4.4 Jirgin Sama da Tsaro:

Masana'antar sararin samaniya da tsaro suna buƙatar tsarin lantarki abin dogaro sosai wanda zai iya jure matsanancin yanayi, girgizawa da watsa bayanai masu sauri.HDI flex PCBs suna da kyau don irin waɗannan aikace-aikacen saboda suna samar da haɗin kai mai yawa, ingantaccen siginar siginar, da juriya ga abubuwan muhalli. Ana amfani da su a cikin tsarin jiragen sama, sadarwar tauraron dan adam, tsarin radar, kayan aikin soja da jirage marasa matuka. Ƙarfin ƙaramin ƙarfi na HDI masu sassaucin ra'ayi na PCBs suna taimakawa wajen haɓaka nauyi, ƙaƙƙarfan tsarin lantarki waɗanda ke ba da damar ingantaccen aiki da ƙarin ayyuka.

4.5 IoT da na'urori masu sawa:

Intanet na Abubuwa (IoT) da na'urori masu sawa suna canza masana'antu daga kiwon lafiya da dacewa zuwa aikin sarrafa gida da saka idanu na masana'antu.HDI masu sassaucin ra'ayi PCBs sune mahimman abubuwan haɗin gwiwa a cikin IoT da na'urori masu sawa saboda ƙaramin nau'in sigar su da babban sassauci. Suna ba da damar haɗa kai tsaye na na'urori masu auna firikwensin, na'urorin sadarwa mara waya, da na'urori masu sarrafawa a cikin na'urori kamar agogo mai wayo, na'urorin motsa jiki, na'urorin gida mai kaifin baki, da na'urori masu auna firikwensin masana'antu. Haɓaka fasahar haɗin kai a cikin HDI flex PCBs yana tabbatar da ingantaccen watsa bayanai, rarraba wutar lantarki, da amincin sigina, yana sa su dace da buƙatun buƙatun IoT da na'urori masu sawa.

5. Abubuwan Tsari don HDI Flex PCB:

Zana PCB mai sassaucin ra'ayi na HDI yana buƙatar yin la'akari da hankali game da tari, tazarar ganowa, sanya sassa, dabarun ƙira mai sauri, da ƙalubalen da ke da alaƙa da haɗawa da masana'anta. Ta hanyar magance waɗannan abubuwan ƙira yadda ya kamata, Capel na iya haɓaka manyan ayyuka HDI masu sassaucin ra'ayi PCBs masu dacewa da aikace-aikace iri-iri.

5.1 Layer Stacking da Routing:

HDI masu sassaucin ra'ayi PCBs yawanci suna buƙatar yadudduka da yawa don cimma manyan haɗin kai.Lokacin zayyana tari mai shimfiɗa, dole ne a yi la'akari da dalilai kamar amincin sigina, rarraba wutar lantarki, da sarrafa zafin jiki. Tsare-tsalle mai tsafta yana taimakawa haɓaka sigina da rage yawan magana tsakanin sawu. Yakamata a shirya hanyar tafiya don rage skew sigina da kuma tabbatar da daidaitaccen madaidaicin matsi. Dole ne a keɓance isasshen sarari don tayoyi da pads don sauƙaƙe haɗin kai tsakanin yadudduka.

5.2 Neman Tazarar Rarrabawa da Kula da Cututtuka:

HDI masu sassaucin ra'ayi PCBs yawanci suna da babban yawa na burbushi, kiyaye daidaitaccen tazara yana da mahimmanci don hana tsangwama da sigina.Dole ne masu zanen kaya su tantance daidai faɗin alamar alama da tazara dangane da abin da ake so. Sarrafa impedance yana da mahimmanci don kiyaye amincin sigina, musamman don sigina masu sauri. Masu ƙira yakamata su lissafta a hankali da sarrafa faɗin alamar gano wuri, tazara, da madaidaicin dielectric don cimma ƙimar da ake so.

5.3 Sanya sassa:

Sanya abubuwan da suka dace yana da mahimmanci don haɓaka hanyar siginar, rage hayaniya da rage girman gaba ɗaya na HDI mai sassaucin ra'ayi PCB.Ya kamata a sanya abubuwan da suka dace da dabara don rage tsawon saƙon sigina da haɓaka kwararar sigina. Yakamata a sanya abubuwan haɗin kai masu sauri kusa tare don rage jinkirin yada sigina da rage haɗarin karkatar da sigina. Hakanan ya kamata masu zanen kaya suyi la'akari da bangarorin kula da yanayin zafi kuma su tabbatar an sanya abubuwan da aka gyara a cikin hanyar da ke ba da damar zubar da zafi.

5.4 Fasahar ƙira mai sauri:

HDI masu sassaucin ra'ayi PCBs yawanci suna ɗaukar watsa bayanai mai sauri inda amincin sigina ke da mahimmanci.Ingantattun dabarun ƙira mai saurin gaske, kamar yadda ake sarrafa impedance routing, bambance-bambancen nau'ikan kewayawa, da madaidaicin tsayin sawu, suna da mahimmanci don rage girman sigina. Ana iya amfani da kayan aikin tantance amincin sigina don kwaikwaya da tabbatar da aikin ƙira mai sauri.

5.5 Ƙalubalen Taro da Ƙirƙira:

Haɗawa da kera HDI masu sassaucin ra'ayi PCBs suna gabatar da ƙalubale da yawa.Halin sassauƙa na PCBs yana buƙatar kulawa da hankali yayin taro don guje wa ɓarna lallausan alamu da abubuwan haɗin gwiwa. Madaidaicin jeri sashi da siyarwa na iya buƙatar kayan aiki na musamman da dabaru. Tsarin ƙirƙira yana buƙatar tabbatar da daidaitaccen jeri na yadudduka da mannewa mai kyau a tsakanin su, wanda zai iya haɗa da ƙarin matakai kamar hakowa Laser ko hoton laser kai tsaye.

Bugu da ƙari, ƙananan girman da babban ɓangaren ɓangaren HDI masu sassaucin ra'ayi na PCB na iya haifar da ƙalubale don dubawa da gwaji. Dabarun dubawa na musamman kamar duban X-ray ana iya buƙata don gano lahani ko gazawa a cikin PCBs. Bugu da ƙari, tun da HDI masu sassaucin ra'ayi PCBs yawanci suna amfani da kayan haɓaka da fasaha, zaɓi da cancantar masu kaya yana da mahimmanci don tabbatar da inganci da amincin samfurin ƙarshe.

6.Future trends na HDI m PCB fasaha:

Makomar fasahar PCB mai sassauƙa ta HDI za ta kasance ta hanyar haɓaka haɗin kai da rikitarwa, ɗaukar kayan haɓakawa, da haɓaka IoT da fasahar sawa. Wadannan dabi'un za su kori masana'antu don haɓaka ƙarami, mafi ƙarfi, da na'urorin lantarki masu aiki da yawa.

6.1 Haɗin kai da rikitarwa:

HDI m PCB fasahar za ta ci gaba da tasowa a cikin shugabanci na kara hadewa da kuma rikitarwa.Yayin da na'urorin lantarki ke zama mafi ƙanƙanta da wadataccen fasali, ana samun karuwar buƙatu na PCBs masu sassaucin ra'ayi na HDI tare da mafi girman girman kewaye da ƙananan sifofi. Wannan yanayin yana faruwa ne ta hanyar ci gaba a cikin tsarin masana'antu da kayan aikin ƙira waɗanda ke ba da damar gano mafi kyawun gani, ƙarami ta hanyar hanyar sadarwa, da filayen haɗin haɗin gwiwa. Haɗa hadaddun kayan aikin lantarki daban-daban akan PCB mai sassauƙa guda ɗaya zai ƙara ƙaruwa

na kowa, rage girman, nauyi da kuma tsarin tsarin gabaɗaya.

6.2 Amfani da kayan haɓakawa:

Domin saduwa da buƙatun babban haɗin kai da aiki, HDI m PCB zai yi amfani da kayan haɓaka.Sabbin kayan aiki tare da ingantattun kayan lantarki, thermal da injuna za su ba da damar ingantaccen siginar siginar, ingantacciyar rarrabuwar zafi da aminci mafi girma. Misali, yin amfani da ƙananan kayan dielectric mai ƙarancin asara zai ba da damar yin aiki da mitoci mafi girma, yayin da manyan kayan haɓakar zafin jiki na iya haɓaka ƙarfin sarrafa thermal na PCBs masu sassauƙa. Bugu da ƙari, ci gaba a cikin kayan sarrafawa kamar gami da jan karfe da polymers masu ɗaukar nauyi za su ba da damar mafi girman ƙarfin ɗaukar halin yanzu da ingantacciyar kulawar impedance.

6.3 Fadada IoT da Fasahar Sawa:

Fadada Intanet na Abubuwa (IoT) da fasahar sawa za su sami babban tasiri akan fasahar PCB mai sassauƙa ta HDI.Yayin da adadin na'urorin da aka haɗa ke ci gaba da girma, za a sami ƙarin buƙatu na PCB masu sassauƙa waɗanda za a iya haɗa su cikin ƙananan nau'i daban-daban. HDI flex PCBs za su taka muhimmiyar rawa a cikin ƙaramar na'urorin da za a iya amfani da su kamar agogo mai wayo, masu kula da motsa jiki da na'urori masu auna lafiya. Waɗannan na'urori galibi suna buƙatar PCB masu sassauƙa don dacewa da jiki da samar da haɗin kai mai ƙarfi da aminci.

Haka kuma, yaduwar na'urorin IoT a cikin masana'antu daban-daban kamar gida mai kaifin baki, kera motoci, da sarrafa kansa na masana'antu zai fitar da buƙatun PCBs masu sassaucin ra'ayi na HDI tare da abubuwan haɓakawa kamar watsa bayanai mai sauri, ƙarancin wutar lantarki, da haɗin kai mara waya. Waɗannan ci gaban za su buƙaci PCBs don tallafawa hadaddun sigina ta hanyar zirga-zirgar sigina, ƙananan abubuwan haɗin gwiwa da haɗin kai tare da firikwensin daban-daban da masu kunnawa.

a takaice, HDI masu sassaucin ra'ayi PCBs sun canza masana'antar lantarki tare da haɗin kai na musamman na sassauci da haɗin kai mai girma. Waɗannan PCBs suna ba da fa'idodi da yawa akan PCBs masu sassaucin ra'ayi na gargajiya, gami da ƙaranci, haɓaka sararin samaniya, ingantacciyar siginar sigina, ingantaccen rarraba wutar lantarki, da ikon ɗaukar manyan abubuwa masu yawa. Waɗannan kaddarorin suna sanya HDI masu sassaucin ra'ayi PCBs dacewa don amfani a cikin masana'antu iri-iri, gami da na'urorin lantarki na mabukaci, na'urorin likitanci, tsarin kera motoci, da aikace-aikacen sararin samaniya. Koyaya, yana da mahimmanci a yi la'akari da la'akari da ƙira da ƙalubalen masana'anta da ke da alaƙa da waɗannan manyan PCBs. Dole ne masu zanen kaya su tsara shimfidar wuri da tukwici don tabbatar da ingantaccen aikin sigina da sarrafa zafi. Bugu da ƙari, tsarin masana'antu na HDI flex PCBs yana buƙatar matakai da dabaru don cimma matakin da ake buƙata na daidaito da aminci. Ci gaba, ana sa ran PCB masu sassaucin ra'ayi na HDI za su ci gaba da haɓaka yayin ci gaban fasaha. Yayin da na'urorin lantarki suka zama ƙarami kuma sun fi rikitarwa, buƙatar HDI masu sassaucin ra'ayi PCBs tare da manyan matakan haɗin kai da aiki za su ƙaru kawai. Wannan zai haifar da ƙarin sabbin abubuwa da ci gaba a fagen, wanda zai haifar da ingantacciyar na'urori masu amfani da lantarki a cikin masana'antu.

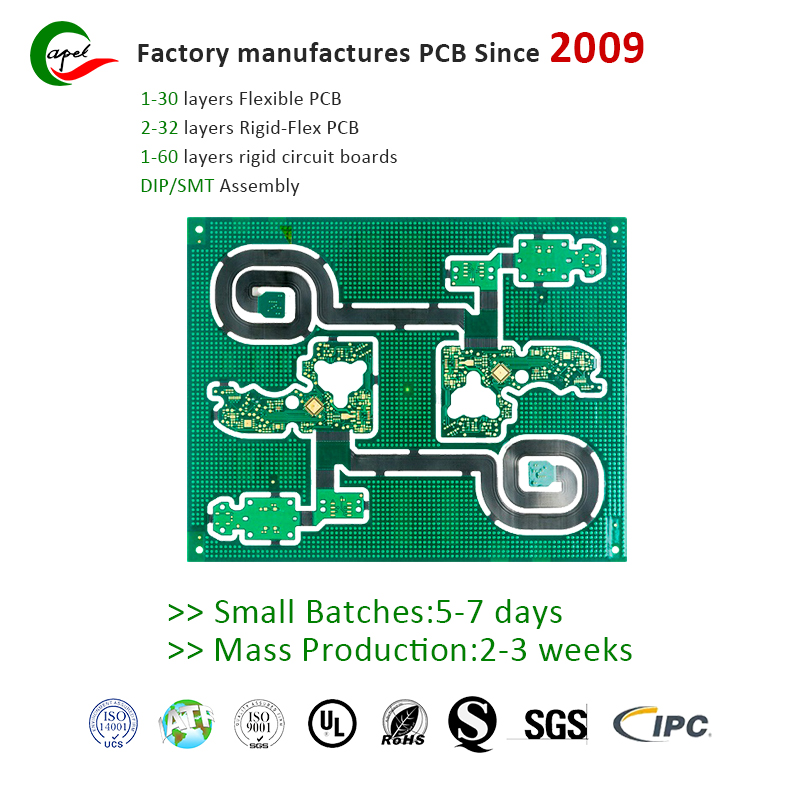

Shenzhen Capel Technology Co., Ltd yana kera kwamfutoci masu sassauƙa masu sassauƙa (PCBs) tun 2009.A halin yanzu, muna iya samar da al'ada 1-30 Layer m bugu da'ira allon. HDI ɗin mu (High Density Interconnect) fasaha na masana'antar PCB mai sassauƙa ya balaga sosai. A cikin shekaru 15 da suka gabata, mun ci gaba da haɓaka fasahar fasaha da kuma tara gogewa mai arziƙi wajen magance matsalolin da suka shafi aikin ga abokan ciniki.

Lokacin aikawa: Agusta-31-2023

Baya