Kwamfutocin da'ira masu sassauƙa (PCBs), waɗanda kuma aka sani da PCBs masu sassauƙa, sun ƙara shahara a cikin 'yan shekarun nan saboda iyawarsu ta musamman ta lanƙwasa. Waɗannan allunan da'ira masu sassauƙa suna da yawa kuma suna samun aikace-aikace a masana'antu da yawa, gami da kera motoci, na'urorin lantarki, kiwon lafiya, da sadarwa. Lokacin yin odar PCBs masu sassauƙa, yana da mahimmanci a fahimci abubuwan da ke tasiri farashin su don cimma ƙimar farashi da inganci.A cikin wannan labarin, za mu shiga cikin mahimman abubuwan da ke yin tasiri akan zance na PCB mai sauƙi, yana ba ku damar yanke shawarar da aka sani lokacin yin oda. Ta hanyar samun ilimi akan waɗannan abubuwan, zaku iya inganta kasafin kuɗin ku kuma ku tabbatar da cewa buƙatun ku na PCB sun yi daidai da takamaiman buƙatun ku da ƙa'idodin masana'antu.

1.Design Complexity:Daya daga cikin manyan abubuwan da suka shafi m PCB zance ne zane hadaddun.

Ƙirƙirar ƙira tana taka muhimmiyar rawa wajen ƙayyade farashin masana'anta na PCB masu sassauƙa. Ƙirar ƙira galibi ta ƙunshi haɗaɗɗiyar kewayawa, ayyuka na ci gaba, da buƙatu na musamman waɗanda ke buƙatar kayan aiki na musamman da matakai. Waɗannan ƙarin buƙatun suna haɓaka lokacin samarwa da ƙoƙari, yana haifar da farashin masana'anta.

Ɗayan al'amari na rikitaccen ƙira shine amfani da kayan aikin farar fata masu kyau. Abubuwan da aka gyara masu kyau suna da kunkuntar filayen gubar, waɗanda ke buƙatar daidaito mafi girma a cikin tsarin masana'anta. Wannan yana buƙatar kayan aiki na musamman da matakai don tabbatar da dacewa daidai. Ƙarin matakai da matakan taka tsantsan da ake buƙata don ƙayyadaddun ƙayyadaddun ƙaƙƙarfan ƙaƙƙarfan ƙaƙƙarfan ƙira da farashi.

Ƙananan radiyoyin lanƙwasa wani abu ne da ke shafar ƙira. Ana san allunan da'irar da'ira masu sassauƙa don iyawar su na lanƙwasa da murɗawa, amma idan radiyoyin lanƙwasa sun yi ƙanƙanta, wannan yana haifar da takura kan tsarin masana'anta. Samun ƙananan radiyon lanƙwasa yana buƙatar zaɓin kayan a hankali da ingantattun dabarun lanƙwasawa don gujewa lalacewa ko nakasar da'ira. Waɗannan ƙarin la'akari suna ƙara rikitar masana'anta da farashi.

Bugu da kari, hadaddun hanyoyin zirga-zirgar da'ira wani bangare ne da ke shafar hadadden tsari. Na'urori masu tasowa galibi suna buƙatar hadaddun sigina, rarraba wutar lantarki, da jiragen ƙasa. Samun ingantacciyar hanya a cikin PCBs masu sassauƙa na iya zama ƙalubale kuma yana iya buƙatar ƙarin matakai kamar fasahohin gyare-gyaren tagulla na musamman ko amfani da makafi da binne ta hanyar. Waɗannan ƙarin buƙatun suna haɓaka rikitaccen masana'anta da farashi.

2.Material selection: Wani key factor a kayyade m PCB zance shi ne zabi na kayan.

Zaɓin kayan abu shine mahimmancin la'akari don ƙayyade farashin PCB mai sassauƙa. Daban-daban substrates suna ba da matakan aiki daban-daban da tasirin farashi. Zaɓin kayan aiki ya dogara da takamaiman buƙatun aikace-aikacen.

Polyimide (PI) sananne ne don manyan abubuwan da yake da kyau, gami da kyakkyawan kwanciyar hankali da sassauci. Zai iya jure yanayin zafi kuma ya dace da aikace-aikace tare da yanayin zafi mai girma. Koyaya, babban aikin polyimide yana zuwa a farashi mafi girma idan aka kwatanta da sauran kayan. Wannan ya faru ne saboda tsarin masana'anta mafi rikitarwa da tsada na kayan albarkatun polyimide.

Polyester (PET) wani abu ne na gama gari don PCBs masu sassauƙa. Ya fi arha fiye da polyimide kuma yana da sassauci mai kyau. PCBs masu sassaucin ra'ayi na tushen Polyester sun dace da aikace-aikace tare da ƙananan buƙatun zafin jiki. Koyaya, kwanciyar hankali na thermal na polyester ba shi da kyau kamar na polyimide, kuma gabaɗayan aikinsa na iya zama ƙasa. Don aikace-aikace masu tsada tare da ƙarancin yanayin aiki, polyesters zaɓi ne mai yuwuwa kuma mai tsada.

PEEK (polyetheretherketone) abu ne mai girma da aka yi amfani da shi a aikace-aikace masu buƙata. Yana da kyawawan kayan inji da kayan zafi kuma ya dace da matsanancin yanayi. Koyaya, PEEK ya fi polyimide da polyester tsada sosai. Ana zaɓin shi sau da yawa don aikace-aikace inda ake buƙatar ingantaccen aiki kuma za'a iya baratar da ƙimar kayan abu mafi girma.

Bugu da ƙari ga kayan da ake amfani da su, sauran kayan da aka yi amfani da su a cikin tsarin masana'antu, irin su laminates, fina-finai masu rufewa da kayan mannewa, suna shafar farashin gaba ɗaya. Farashin waɗannan ƙarin kayan na iya bambanta dangane da ingancinsu da halayen aikinsu. Misali, manyan laminates masu inganci tare da ingantattun kayan lantarki ko fina-finai na musamman na murfin tare da ingantaccen kariya daga abubuwan muhalli na iya ƙarawa gabaɗayan farashin PCB mai sassauƙa.

3.Quantity da wuyar warwarewa:Yawan m PCB ake bukata taka muhimmiyar rawa a kayyade zance.

Adadin da ake buƙata shine babban al'amari lokacin da farashin PCBs masu sassauƙa. Masu masana'anta yawanci suna aiwatar da farashi na tushen yawa, wanda ke nufin cewa mafi girman adadin, yana rage farashin rukunin. Wannan saboda manyan umarni suna ba da damar ingantacciyar tattalin arziƙin sikelin kuma don haka rage farashin samarwa

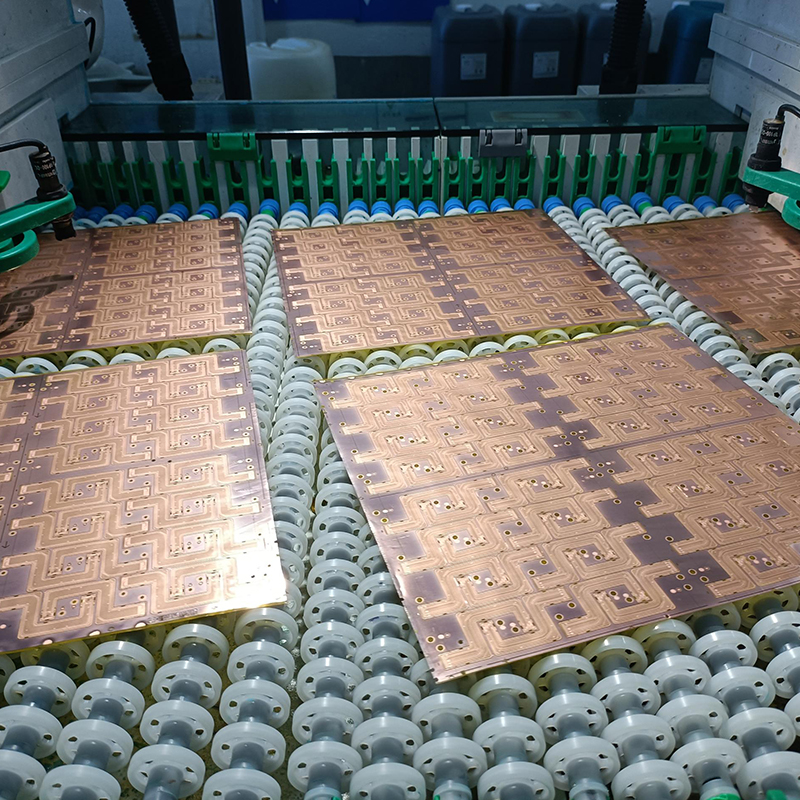

Wata hanya don inganta amfani da kayan aiki da ingancin masana'antu shine panelization. Ƙaddamarwa ta ƙunshi haɗa ƙananan PCBs masu yawa zuwa babban panel. Ta hanyar tsara dabarun ƙira akan bangarori, masana'anta na iya rage sharar gida da haɓaka yawan aiki yayin aikin masana'anta.

Haɗin kai yana da fa'idodi da yawa. Na farko, yana rage sharar kayan abu ta hanyar yin amfani da mafi kyawun sararin samaniya a kan panel. Maimakon samar da PCB daban-daban tare da iyakokinsu da tazara, masana'antun za su iya sanya ƙira da yawa akan kwamiti guda, suna yin mafi yawan sararin da ba a yi amfani da su a tsakanin. Wannan yana haifar da tanadin kayan abu mai mahimmanci da raguwar farashi.

Bugu da ƙari, panelization yana sauƙaƙe tsarin masana'antu. Yana ba da damar ƙarin sarrafa kansa da ingantaccen tsarin samarwa kamar yadda ake iya sarrafa PCB da yawa a lokaci guda. Wannan yana ƙara yawan aiki kuma yana rage lokacin masana'antu, yana haifar da gajeriyar lokutan jagora da ƙananan farashi. Ingantaccen aikin panel yana buƙatar tsarawa a hankali da la'akari da abubuwa kamar girman PCB, buƙatun ƙira, da ƙwarewar masana'antu. Masu ƙera za su iya amfani da kayan aikin software na musamman don taimakawa a cikin tsarin ƙaddamarwa, tabbatar da daidaitawa mafi kyau da ingantaccen amfani da kayan.

Bugu da ƙari, ƙirar panel ya fi sauƙi don sarrafawa da sufuri. Bayan an gama aikin masana'anta, ana iya raba bangarorin zuwa PCB guda ɗaya. Wannan yana sauƙaƙe marufi kuma yana rage haɗarin lalacewa yayin jigilar kaya, wanda a ƙarshe yana adana kuɗi.

4.Surface Finish da Copper Weight: Surface gama da jan karfe nauyi ne key la'akari a cikinm PCB masana'antu tsari.

Ƙarshen farfajiyar wani muhimmin al'amari ne na masana'antar PCB saboda kai tsaye yana rinjayar solderability da karko na hukumar. Jiyya na saman yana samar da kariya mai kariya akan burbushin jan karfe da aka fallasa, yana hana iskar shaka da kuma tabbatar da amintattun gidajen abinci. Daban-daban jiyya na saman suna da farashi da fa'idodi daban-daban.

Ƙarshen gama gari shine HASL (Hot Air Solder Leveling), wanda ya haɗa da shafa Layer na solder a cikin alamun tagulla sannan kuma amfani da iska mai zafi don daidaita su. HASL yana da tsada-tsari kuma yana ba da ingantaccen siyarwa, amma maiyuwa bazai dace da kayan kwalliya mai kyau ba saboda yanayin da bai dace ba da yake samarwa.

ENIG (Electroless Nickel Immersion Gold) wani magani ne da ake amfani da shi sosai. Ya haɗa da ajiye ɗan ƙaramin nickel na nickel a kan alamun tagulla, sannan da zinari na biye. Kyakkyawan solderability na ENIG, saman lebur, da juriya na lalata sun sa ya dace da abubuwan da aka gyara masu kyau da ƙira mai yawa. Koyaya, ENIG yana da tsada mai tsada idan aka kwatanta da sauran jiyya na saman.

OSP (Organic Solderability Preservative) magani ne na saman ƙasa wanda ya ƙunshi aikace-aikacen siriri na kayan halitta don kare alamun tagulla. OSP yana ba da ingantaccen solderability, tsarawa da ingantaccen farashi. Koyaya, baya da ƙarfi kamar sauran ƙarewa kuma yana iya buƙatar kulawa da hankali yayin haɗuwa.

Nauyin (a cikin ounces) na jan karfe a cikin PCB yana ƙayyade aiki da aikin allo. Yadudduka masu kauri na jan ƙarfe suna ba da ƙarancin juriya kuma suna iya ɗaukar igiyoyin ruwa mafi girma, yana sa su dace da aikace-aikacen wutar lantarki. Koyaya, yadudduka masu kauri na jan ƙarfe suna buƙatar ƙarin kayan abu da ƙwararrun dabarun masana'antu, don haka haɓaka ƙimar PCB gabaɗaya. Sabanin haka, ƙananan yadudduka na tagulla sun dace da aikace-aikacen ƙananan ƙarfi ko aikace-aikace inda matsalolin sararin samaniya ya kasance. Suna buƙatar ƙarancin kayan aiki kuma sun fi tasiri. Zaɓin nauyin jan ƙarfe ya dogara da takamaiman buƙatun ƙirar PCB da aikin da aka yi niyya.

5.Fasahar kere-kereda Mold: Dabarun masana'antu da kayan aikin da ake amfani da su don samar da PCB masu sassauƙa kuma suna shafar farashin.

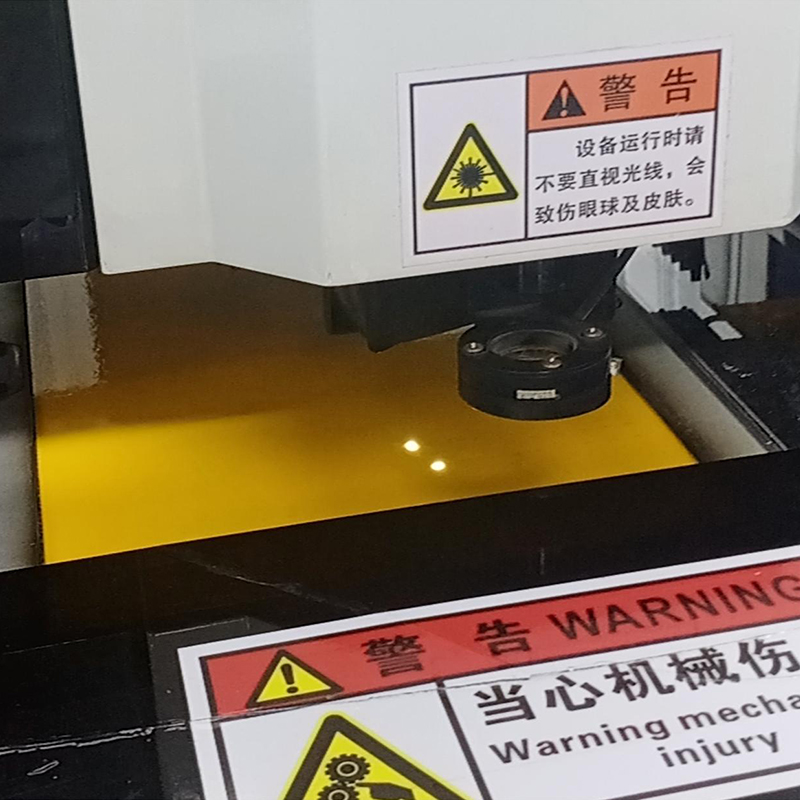

Fasahar kere kere tana taka muhimmiyar rawa wajen samar da PCB masu sassauƙa kuma yana da babban tasiri akan farashi. Na'urori masu tasowa, irin su hakowa na Laser da ginawa na tsari (SBU), na iya ƙirƙirar ƙira mai mahimmanci da ƙima, amma waɗannan hanyoyin sau da yawa suna zuwa tare da farashin samarwa. Laser hakowa zai iya samar da lafiya vias da ƙananan ramuka, kunna high-yawa da'irar a m PCBs. Duk da haka, yin amfani da fasahar Laser da kuma daidaitattun da ake bukata don tsari yana ƙara yawan farashin samarwa.

Sequential build up (SBU) wata fasahar kere-kere ce ta ci gaba wacce ta ƙunshi haɗa da'irori masu sassauƙa da yawa don ƙirƙirar ƙira mai rikitarwa. Wannan fasaha yana ƙara ƙirar ƙira kuma yana ba da damar haɗin ayyuka daban-daban a cikin PCB mai sassauƙa guda ɗaya. Koyaya, ƙarin rikitarwa a cikin tsarin masana'anta yana haɓaka farashin samarwa.

Baya ga fasahohin masana'antu, ƙayyadaddun hanyoyin da ke tattare da samar da PCB masu sassauƙa kuma na iya shafar farashi. Tsari kamar plating, etching, da lamination matakai ne masu mahimmanci wajen kera PCB mai sassauƙa mai cikakken aiki kuma abin dogaro. Ingancin waɗannan kayan aikin, gami da kayan da ake amfani da su da matakin daidaitattun da ake buƙata, yana shafar ƙimar gabaɗaya

Kayan aiki na atomatik da sabbin kayan aikin suna taimakawa haɓaka aiki da inganci a cikin tsarin masana'anta. Na'ura mai sarrafa kansa, robotics, da tsarin sarrafa kwamfuta (CAM) na iya sauƙaƙe samarwa, rage kuskuren ɗan adam, da haɓaka aikin masana'anta. Koyaya, aiwatar da irin wannan sarrafa kansa na iya haifar da ƙarin farashi, gami da saka hannun jari na gaba a kayan aiki da horar da ma'aikata.

Bugu da ƙari, yin amfani da sababbin kayan aiki da fasaha, irin su software na ƙira na PCB da kayan dubawa, na iya taimakawa wajen haɓaka farashin. Waɗannan kayan aikin galibi suna buƙatar ƙwarewa na musamman, kulawa da sabuntawa, waɗanda duk suna ƙara ƙimar gabaɗaya. Masu sana'a suna buƙatar yin la'akari a hankali ma'auni tsakanin fasahar masana'antu, matakai, aiki da kai da sabbin kayan aikin don cimma farashi da ma'auni mai inganci da ake buƙata don samar da PCB mai sassauƙa. Ta hanyar nazarin ƙayyadaddun buƙatun aikin da aiki tare da abokan ciniki, masana'antun zasu iya ƙayyade mafi dacewa fasaha da matakai yayin da rage farashin da kuma tabbatar da mafi kyawun sakamakon samarwa.

6.Lokacin bayarwa da jigilar kaya:Lokacin jagorar da ake buƙata shine muhimmin al'amari da ke shafar zance mai sassauƙa na PCB.

Idan ya zo ga lokacin jagorar PCB mai sassauƙa, lokacin jagora yana taka muhimmiyar rawa. Lokacin jagora shine lokacin da ake ɗauka don masana'anta don kammala samarwa kuma su kasance a shirye don oda don jigilar kaya. Abubuwa da yawa suna shafar lokutan jagoranci, gami da sarƙaƙƙiyar ƙira, adadin PCBs da aka yi oda, da nauyin aikin masana'anta na yanzu.

Umarni na gaggawa ko tsauraran jadawali galibi suna buƙatar masana'anta don ba da fifikon samarwa da ware ƙarin albarkatu don saduwa da ranar ƙarshe. A irin waɗannan lokuta, samarwa na iya buƙatar haɓakawa, wanda zai iya haifar da ƙarin farashi. Masu sana'a na iya cajin kuɗaɗen gaggawa ko aiwatar da hanyoyin kulawa na musamman don tabbatar da cewa an ƙera PCB masu sassauƙa da isar da su cikin ƙayyadaddun lokacin.

Har ila yau, farashin jigilar kayayyaki yana rinjayar gaba ɗaya farashin PCB mai sassauƙa. Ana ƙayyade farashin jigilar kaya da abubuwa da yawa. Na farko, wurin bayarwa yana taka muhimmiyar rawa a cikin farashin jigilar kaya. Yin jigilar kaya zuwa wurare masu nisa ko na nesa na iya haɗawa da ƙarin farashi saboda ƙarin cajin jigilar kaya. Bugu da ƙari, gaggawar isarwa kuma zai shafi farashin jigilar kayayyaki. Idan abokin ciniki yana buƙatar jigilar gaggawa ko na dare, farashin jigilar kaya zai yi girma idan aka kwatanta da daidaitattun zaɓuɓɓukan jigilar kaya.

Darajar oda kuma tana shafar farashin jigilar kaya. Wasu masana'antun na iya bayar da jigilar kaya kyauta ko rangwame akan manyan oda a matsayin abin ƙarfafawa abokan ciniki yin oda mai yawa. A gefe guda, don ƙananan umarni, cajin jigilar kaya na iya zama mai girma don biyan kuɗin da ke cikin marufi da sarrafawa.

Don tabbatar da ingantaccen jigilar kayayyaki da rage farashi, masana'antun na iya yin aiki tare da masu samar da kayan aiki don tantance hanyar jigilar kayayyaki mafi inganci. Wannan na iya haɗawa da zabar jigilar jigilar kaya daidai, yin shawarwari kan farashin jigilar kaya, da haɓaka marufi don rage nauyi da girma.

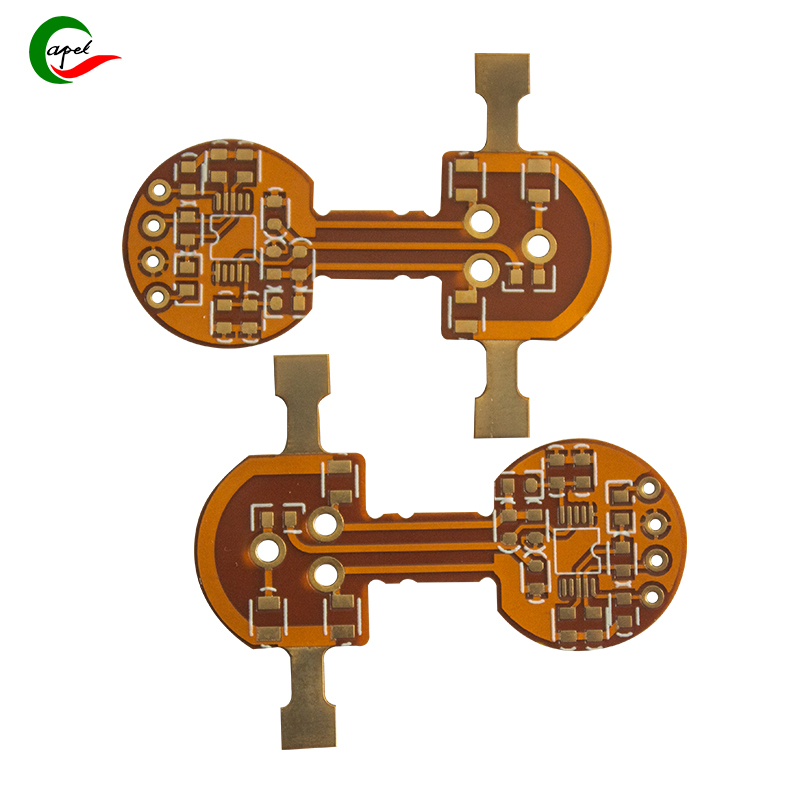

A takaice,akwai abubuwa da yawa waɗanda ke shafar zance na PCB mai sassauƙa. Abokan ciniki waɗanda ke da cikakkiyar fahimtar waɗannan abubuwan zasu iya yanke shawara mai fa'ida da haɓaka ayyukan masana'anta.Ƙirƙirar ƙira, zaɓin kayan abu da yawa sune mahimman abubuwan da ke shafar farashin PCB mai sassauƙa.Mafi rikitarwa da ƙira, mafi girman farashi. Zaɓuɓɓukan kayan abu, kamar zabar babban inganci mai inganci ko ƙarewar ƙasa, kuma na iya shafar farashin. Hakanan, yin oda mafi girma sau da yawa yana haifar da ragi mai yawa. Sauran abubuwan, kamar su katako, nauyin jan karfe, dabarun ƙirƙira da kayan aiki, suma suna taka rawa wajen tantance farashi. Paneling yana ba da damar ingantaccen amfani da kayan aiki kuma yana rage farashi. Nauyin jan karfe yana rinjayar adadin jan karfe da aka yi amfani da shi, wanda ke rinjayar farashi da aiki na PCB mai sassauci. Dabarun masana'antu da kayan aiki, kamar amfani da fasaha na zamani ko kayan aiki na musamman, na iya shafar farashin. A ƙarshe, lokacin jagora da jigilar kaya sune mahimman la'akari. Ƙarin ƙarin caji na iya yin amfani da odar gaggawa ko haɓakar samarwa, kuma farashin jigilar kaya ya dogara da dalilai kamar wuri, gaggawa, da ƙimar oda. Ta hanyar yin la'akari da waɗannan abubuwan a hankali da aiki tare da ƙwararrun masana'anta na PCB masu aminci, kamfanoni za su iya tsara PCB mai sauƙi mai tsada da inganci wanda ya dace da takamaiman bukatunsu.Shenzhen Capel Technology Co., Ltd yana kera kwamfutoci masu sassauƙa masu sassauƙa (PCBs) tun 2009.A halin yanzu, muna iya samar da al'ada 1-30 Layer m bugu da'ira allon. HDI ɗin mu (High Density Interconnect) fasaha na masana'antar PCB mai sassauƙa ya balaga sosai. A cikin shekaru 15 da suka gabata, mun ci gaba da haɓaka fasahar fasaha da kuma tara gogewa mai arziƙi wajen magance matsalolin da suka shafi aikin ga abokan ciniki.

Lokacin aikawa: Agusta-31-2023

Baya