Sanannen abu ne cewa mafi kyawun fasalin allunan da'ira shine ba da izinin tsararrun shimfidar wuri a cikin ƙunƙun wurare. Koyaya, idan yazo ga OEM PCBA (Masana'antar kayan aiki na asali Buga Majalisar Gudanar da Wuta) ƙira, ƙarancin sarrafawa na musamman, injiniyoyi sun shawo kan gazawa da ƙalubale da yawa. Na gaba, wannan labarin zai bayyana iyakokin ƙira PCB mai ƙarfi-Flex tare da rashin ƙarfi mai sarrafawa.

Tsare-tsare-Flex PCB Design

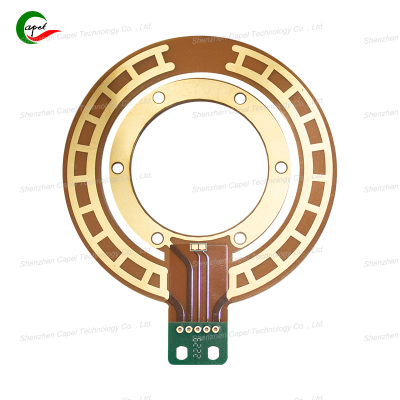

Rigid-Flex PCBs matasan allo ne masu tsauri da sassauƙa, suna haɗa fasahohin biyu zuwa naúrar guda ɗaya. Wannan tsarin ƙira yana ba da damar ƙarin sassauci a aikace-aikace inda sarari ke da ƙima, kamar a cikin na'urorin likitanci, sararin samaniya, da na'urorin lantarki masu amfani. Ikon lanƙwasa da ninka PCB ba tare da lalata amincin sa ba yana da fa'ida mai mahimmanci. Koyaya, wannan sassauci yana zuwa tare da nasa ƙalubale, musamman idan ya zo ga sarrafa impedance.

Abubuwan Bukatun Rigid-Flex PCBs

Sarrafa impedance yana da mahimmanci a aikace-aikacen dijital mai sauri da RF (Mitar Radiyo). Rikicin PCB yana rinjayar amincin sigina, wanda zai iya haifar da al'amura kamar asarar sigina, tunani, da kuma yin magana. Don PCBs mai ƙarfi-Flex, kiyaye daidaitaccen rashin ƙarfi a cikin ƙirar yana da mahimmanci don tabbatar da ingantaccen aiki.

Yawanci, kewayon impedance na Rigid-Flex PCBs an ƙayyade tsakanin 50 ohms da 75 ohms, dangane da aikace-aikacen. Koyaya, cimma wannan rashin ƙarfi mai sarrafawa na iya zama ƙalubale saboda keɓantattun halaye na ƙirar Rigid-Flex. Abubuwan da aka yi amfani da su, kauri na yadudduka, da kaddarorin dielectric duk suna taka muhimmiyar rawa wajen ƙayyade rashin ƙarfi.

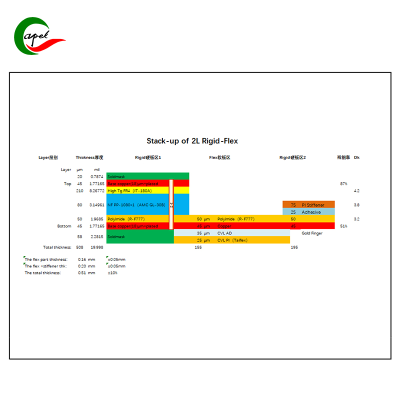

Iyaka na Rigid-Flex PCB Stack-Up

Ɗayan ƙayyadaddun ƙayyadaddun ƙayyadaddun ƙayyadaddun ƙayyadaddun ƙayyadaddun PCBs na Rigid-Flex tare da impedance mai sarrafawa shine daidaitawar tari. Tari-up yana nufin tsari na yadudduka a cikin PCB, wanda zai iya haɗawa da yadudduka na jan karfe, kayan lantarki, da yadudduka masu ɗaure. A cikin ƙirar Rigid-Flex, tarawa dole ne ya ƙunshi sassa biyu masu ƙarfi da sassauƙa, waɗanda zasu iya rikitar da tsarin sarrafa impedance.

1. Matsalolin Material

Abubuwan da aka yi amfani da su a cikin PCBs Rigid-Flex na iya yin tasiri mai mahimmanci. Kayan aiki masu sassauƙa sau da yawa suna da maɓalli daban-daban na dielectric idan aka kwatanta da m kayan. Wannan rashin daidaituwa na iya haifar da bambance-bambance a cikin impedance wanda ke da wuyar sarrafawa. Bugu da ƙari, zaɓin kayan zai iya shafar aikin PCB gabaɗaya, gami da kwanciyar hankali da ƙarfin injina.

2. Canjin Kauri na Layer

Kaurin yadudduka a cikin PCB Rigid-Flex na iya bambanta sosai tsakanin sassauƙa da sassauƙa. Wannan sauye-sauyen na iya haifar da ƙalubale wajen kiyaye daidaituwar matsa lamba a ko'ina cikin hukumar. Dole ne injiniyoyi su lissafta kaurin kowane Layer a tsanake don tabbatar da cewa abin da ya rage ya kasance cikin kewayon da aka kayyade.

3. Lanƙwasa Radius la'akari

Lanƙwasa radius na Rigid-Flex PCB wani muhimmin al'amari ne wanda zai iya shafar impedance. Lokacin da PCB ya lanƙwasa, dielectric abu zai iya damfara ko mikewa, musanyawa da impedance halaye. Dole ne masu zanen kaya suyi lissafin radius na lanƙwasa a cikin lissafin su don tabbatar da cewa impedance ya kasance barga yayin aiki.

4. Samar da Haƙuri

Haƙuri na masana'antu kuma na iya haifar da ƙalubale wajen samun rashin ƙarfi mai ƙarfi a cikin PCBs Rigid-Flex. Bambance-bambance a cikin tsarin masana'antu na iya haifar da rashin daidaituwa a cikin kauri na Layer, kaddarorin kayan aiki, da girma gaba ɗaya. Waɗannan rashin daidaituwa na iya haifar da rashin daidaituwa na rashin daidaituwa wanda zai iya lalata amincin sigina.

5. Gwaji da Tabbatarwa

Gwajin Rigid-Flex PCBs don rashin ƙarfi mai sarrafawa na iya zama mafi rikitarwa fiye da PCBs na gargajiya ko masu sassauƙa. Ana iya buƙatar kayan aiki na musamman da dabaru don auna daidaitaccen rashin ƙarfi a cikin sassa daban-daban na hukumar. Wannan ƙarin rikitarwa na iya ƙara lokaci da farashin da ke hade da ƙira da tsarin masana'antu.

Lokacin aikawa: Oktoba-28-2024

Baya