Gabatarwa:

A cikin wannan shafin yanar gizon, za mu shiga cikin cikakkun bayanai na yadda yadudduka a cikin allon da'ira mai tsauri, bincika dabaru daban-daban da aka yi amfani da su wajen aiwatarwa.

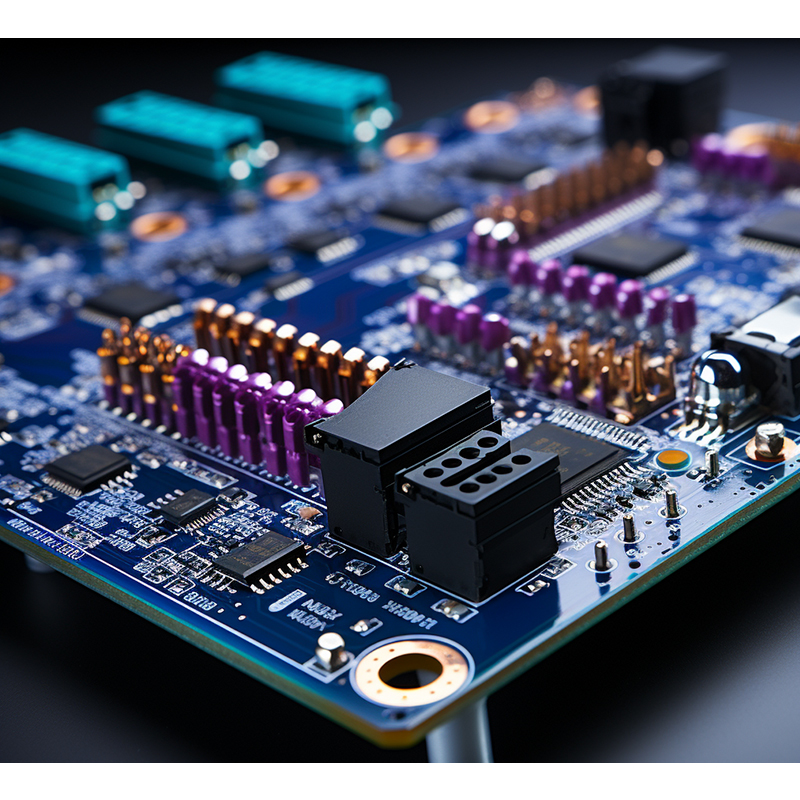

Allolin da'ira masu tsattsauran ra'ayi sun shahara a masana'antu daban-daban da suka haɗa da sararin samaniya, likitanci, da na'urorin lantarki. Waɗannan allunan sun bambanta da cewa suna haɗa nau'ikan kewayawa masu sassauƙa tare da sassan sassauƙa, suna ba da ƙarfi da sassauci. Ɗaya daga cikin mahimman al'amurran da ke tabbatar da aiki da amincin kwalaye masu tsauri shine fasahar haɗin kai da ake amfani da su don haɗa nau'i daban-daban.

1. Fasahar haɗin gwiwa:

Ana amfani da fasahar haɗin kai mai mannewa ko'ina a cikin masana'antar allo mai sassauƙa. Ya ƙunshi yin amfani da manne na musamman wanda ya ƙunshi ma'aunin maganin zafi. Ana amfani da waɗannan adhesives don haɗa yadudduka masu sassauƙa zuwa tsayayyen sassan allunan kewayawa. Adhesive ba kawai yana ba da tallafi na tsari ba amma yana tabbatar da haɗin wutar lantarki tsakanin yadudduka.

A lokacin aikin masana'antu, ana amfani da manne a cikin hanyar sarrafawa kuma an daidaita matakan daidai kafin a haɗa su tare a ƙarƙashin zafi da matsa lamba. Wannan yana tabbatar da haɗin gwiwa mai ƙarfi tsakanin yadudduka, yana haifar da allon kewayawa mai tsauri tare da kyawawan kayan aikin injiniya da lantarki.

2. Fasaha Dutsen Surface (SMT):

Wata shahararriyar hanyar haɗa madaidaitan madauri mai sassauƙa shine ta amfani da fasahar ɗorawa saman (SMT). SMT ya ƙunshi ɗora abubuwan hawan saman saman kai tsaye zuwa wani yanki mai tsauri na allon kewayawa sannan kuma a sayar da waɗannan abubuwan zuwa ga pads. Wannan fasaha tana ba da ingantaccen kuma ingantaccen hanya don haɗa yadudduka yayin tabbatar da haɗin wutar lantarki a tsakanin su.

A cikin SMT, an ƙera yadudduka masu tsauri da sassauƙa tare da madaidaicin tayoyi da pads don sauƙaƙe aikin siyarwa. Aiwatar da manna solder zuwa wurin kushin kuma sanya sashin daidai. Sannan ana sanya allon da'irar ta hanyar sake yin siyar da kaya, inda manna mai siyar ya narke kuma ya haɗa yadudduka tare, yana haifar da haɗin gwiwa mai ƙarfi.

3. Ta hanyar rami:

Don samun ingantacciyar ƙarfin injina da haɗin wutar lantarki, ƙaƙƙarfan allon kewayawa sau da yawa suna amfani da platin rami. Dabarar ta ƙunshi hako ramuka a cikin yadudduka da yin amfani da kayan aiki a cikin waɗannan ramukan. Wani abu mai ɗaukar nauyi (yawanci jan ƙarfe) ana saka wuta akan bangon rami, yana tabbatar da haɗin gwiwa mai ƙarfi da haɗin lantarki tsakanin yadudduka.

Plating ta hanyar rami yana ba da ƙarin tallafi ga allunan sassauƙa mai tsauri kuma yana rage haɗarin lalata ko gazawa a cikin mahalli mai tsananin damuwa. Don samun sakamako mafi kyau, ana buƙatar sanya ramukan ramuka a hankali don daidaitawa tare da tawul da tawul akan yadudduka daban-daban don cimma amintacciyar haɗi.

A Ƙarshe:

Fasahar manne da aka yi amfani da ita a cikin allunan da'ira masu tsauri suna taka muhimmiyar rawa wajen tabbatar da ingancin tsarin su da aikin lantarki. Adhesion, fasahar hawan sama da kuma platin rami ana amfani da su sosai don haɗa yadudduka daban-daban. Kowace fasaha tana da fa'ida kuma an zaɓi ta bisa ƙayyadaddun buƙatun ƙirar PCB da aikace-aikacen.

Ta hanyar fahimtar dabarun haɗin kai da aka yi amfani da su a cikin allunan da'ira masu ƙarfi, masana'anta da masu ƙira za su iya ƙirƙirar taruka masu ƙarfi da aminci. Waɗannan allunan da'ira na ci gaba suna biyan buƙatun fasahar zamani, suna ba da damar aiwatar da na'urorin lantarki masu sassauƙa da dorewa a masana'antu daban-daban.

Lokacin aikawa: Satumba 18-2023

Baya