Shin kun taɓa mamakin yadda ake gwada aikin hukumar da'ira mai ƙarfi? Kada ku yi shakka! A cikin wannan shafin yanar gizon, za mu bincika hanyoyi da dabaru daban-daban don tabbatar da aikin da ya dace na allunan da'ira mai ƙarfi. Ko kai ƙwararren ƙwararren ƙwararren ƙwararren ne ko kuma sababbi a fagen, waɗannan nasihu da dabaru za su taimake ka ka gwada aikin allunan da'ira mai ƙarfi yadda ya kamata.

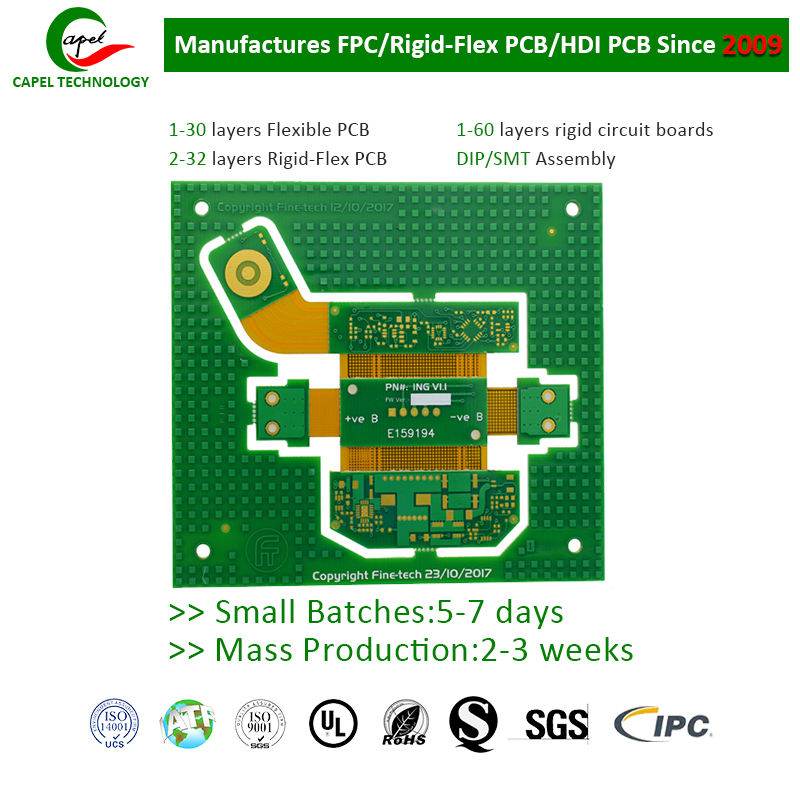

Kafin mu nutse cikin hanyoyin gwaji daban-daban, bari mu ɗan fayyace menene ma'anar da'ira mai tsauri. Kwamfuta masu tsattsauran ra'ayi suna haɗuwa da katako mai tsauri da sassauƙa, ƙirƙirar ƙirar ƙirar ƙirar da ke ba da mafi kyawun duniyoyin biyu. Ana amfani da waɗannan alluna yawanci a aikace-aikace inda sarari ke da iyaka kuma dorewa da aminci suna da mahimmanci.

Yanzu, bari mu matsa zuwa babban jigon wannan labarin - gwada aikin kwalayen da'ira mai ƙarfi. Akwai gwaje-gwaje da yawa da za ku iya yi don tabbatar da cewa hukumar ku tana aiki kamar yadda aka zata. Bari mu bincika wasu daga cikin waɗannan gwaje-gwaje daki-daki.

1. Duban gani don tsayayyen allon kewayawa:

Mataki na farko na gwada aikin hukumar da'ira mai ƙarfi shine a duba ta gani don kowace lahani ta jiki ko lahani. Nemo kowane alamun fashe, karyewa, al'amurran walda ko rashin daidaituwa. Wannan muhimmin mataki ne na farko na gano duk wasu batutuwan da ke bayyane waɗanda za su iya shafar ayyukan hukumar gaba ɗaya.

2. Gwajin ci gaba mai ƙarfi pcb allunan pcb:

Ana yin gwajin ci gaba don bincika cewa haɗin wutar lantarki a allon kewayawa ba su da inganci. Yin amfani da multimeter, zaku iya tantancewa da sauri idan an sami hutu ko buɗewa a cikin alamar da ke gudana. Ta hanyar bincika wuraren haɗin kai daban-daban, zaku iya tabbatar da cewa kewaye ta cika kuma sigina suna gudana daidai.

3. Gwajin impedance don ƙaƙƙarfan allunan sassauƙa:

Gwajin impedance yana da mahimmanci don tabbatar da cewa ma'aunin ma'auni a kan allon da'ira suna cikin ƙayyadaddun iyaka. Wannan gwajin yana tabbatar da cewa duk wani rashin daidaituwa na impedance bai shafe siginar ba, wanda in ba haka ba zai iya haifar da matsalolin ingancin siginar.

4. Gwajin aiki don ƙaƙƙarfan allon da'ira bugu:

Gwajin aiki ya ƙunshi tabbatar da aikin hukumar da'ira ta hanyar gwada ayyukanta daban-daban. Wannan na iya haɗawa da gwaje-gwajen bayanai da abubuwan fitarwa, gudanar da takamaiman shirye-shirye ko lamba, da kwaikwayi yanayin rayuwa na gaske don tabbatar da hukumar tana aiki kamar yadda aka zata.

5. Gwajin muhalli don tsattsauran ra'ayi na pcb mai sassauƙa:

Allolin da'ira mai ƙarfi-sauƙaƙa sau da yawa ana fallasa ga mabanbantan yanayin muhalli. Don haka, gwajin muhalli ya zama dole don kimanta aikin allunan da'irar ƙarƙashin yanayi daban-daban kamar zazzabi, zafi, girgiza, ko damuwa mai zafi. Wannan gwajin yana taimakawa tabbatar da cewa hukumar zata iya jure yanayin aiki da ake sa ran ba tare da wani lahani na aiki ba.

6. Gwajin amincin sigina don allunan da'ira masu sassauƙa na inid:

Ana yin gwajin ingancin siginar don tabbatar da cewa ana watsa siginar ta cikin allon da'ira ba tare da wata karkata ko tsangwama ba. Gwajin ya haɗa da nazarin ingancin sigina da auna ma'auni kamar crosstalk, jitter da zanen ido don tabbatar da kyakkyawan aiki.

Baya ga waɗannan ƙayyadaddun gwaje-gwajen, yana da mahimmanci a bi mafi kyawun ayyuka yayin ƙira da matakan ƙira don tabbatar da babbar dama ta samun kwamiti mai ƙarfi mai ƙarfi mai aiki da kyau. Wannan ya haɗa da cikakken nazari na ƙira, zaɓin kayan da ya dace, da daidaitoingancin dubawa a lokacin masana'antu.

A takaice:

Gwajin aikin hukumar da'ira mai tsattsauran ra'ayi mataki ne mai mahimmanci don tabbatar da aikinsa da ya dace. Ta hanyar dubawa na gani, gwajin ci gaba, gwajin rashin ƙarfi, gwajin aiki, gwajin muhalli, da gwajin amincin sigina, zaku iya ganowa da warware duk wata matsala mai yuwuwa wacce zata iya shafar aikin hukumar ku. Ta bin waɗannan hanyoyin gwaji da mafi kyawun ayyuka, za ku iya samun kwarin gwiwa ga aiki da amincin kwalayen da'ira mai tsauri.

Lokacin aikawa: Satumba 18-2023

Baya