Gabatarwa:

Yayin da buƙatun na'urori masu wayo, ƙananan na'urorin lantarki ke ci gaba da haɓaka, masana'antun suna ci gaba da haɓakawa don biyan waɗannan buƙatun. Rigid-flex printed board (PCBs) sun tabbatar da zama masu canza wasa, suna ba da damar ƙira iri-iri da inganci a cikin kayan lantarki na zamani. Koyaya, akwai kuskuren gama gari cewa kera PCBs masu ƙarfi na buƙatar kayan aikin masana'anta na musamman. A cikin wannan shafi, za mu warware wannan tatsuniya kuma mu tattauna dalilin da yasa wannan kayan aikin na musamman bai zama dole ba.

1. Fahimtar allo mai tsauri:

PCB mai ƙarfi-sauƙaƙƙiya yana haɗa fa'idodin katako mai ƙarfi da sassauƙa don haɓaka ƙirar ƙira, haɓaka aminci da rage farashin taro. Waɗannan allunan sun ƙunshi haɗe-haɗe na maɗaukaki masu ƙarfi da sassauƙa, an haɗa su ta amfani da plated ta ramuka, manne mai ɗaurewa, ko masu haɗawa masu cirewa. Tsarinsa na musamman yana ba shi damar lanƙwasa, ninka ko murɗawa don dacewa cikin matsakaitattun wurare da kuma ɗaukar ƙira mai sarƙaƙƙiya.

2. Yana buƙatar kayan aiki na musamman:

Sabanin sanannen imani, saka hannun jari a cikin ƙwararrun kayan aikin masana'anta masu ƙarfi ba koyaushe ba ne. Yayin da waɗannan allunan ke buƙatar ƙarin la'akari saboda gina su, yawancin hanyoyin masana'antu da kayan aikin har yanzu ana iya amfani da su. Kayan aikin masana'antu na zamani suna sanye da injuna na ci gaba don samar da bangarori masu tsauri ba tare da buƙatar kayan aiki na musamman ba.

3. Sarrafa kayan aiki masu sassauƙa:

Ɗaya daga cikin mahimman al'amuran ƙera PCBs masu ƙarfi shine sarrafawa da sarrafa kayan sassauƙa. Waɗannan kayan na iya zama masu rauni kuma suna buƙatar kulawa ta musamman yayin masana'anta. Koyaya, tare da ingantaccen horo da ingantattun hanyoyin masana'antu, kayan aikin da ake dasu zasu iya sarrafa waɗannan kayan yadda yakamata. gyare-gyare ga hanyoyin matsewa, saitunan isar da saƙo da dabarun sarrafawa na iya tabbatar da daidaitaccen sarrafa kayan sassauƙa.

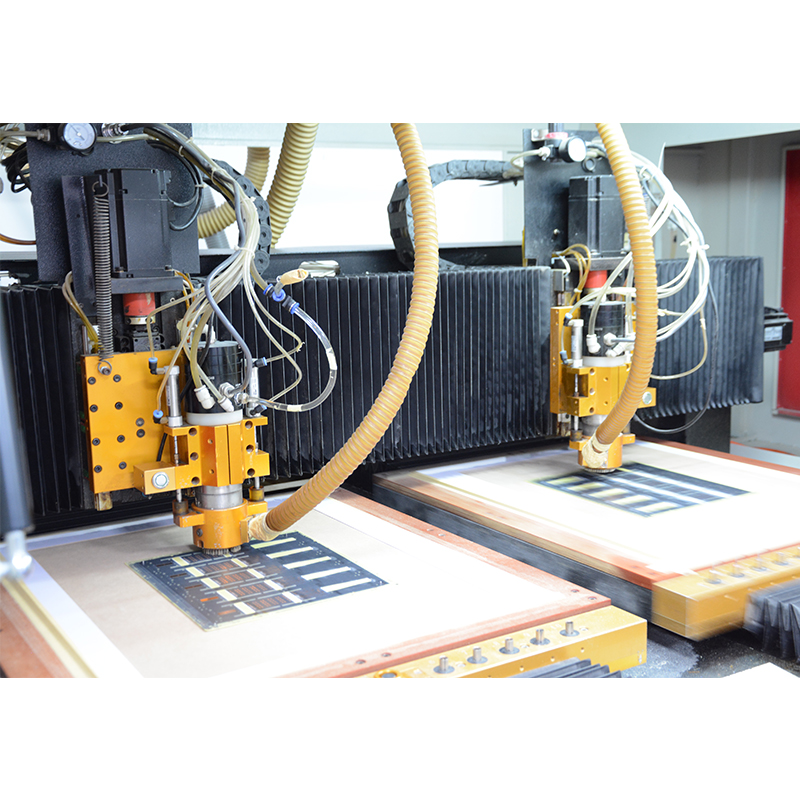

4. Hakowa da Rarraba Ta Ramuka:

Alƙalai masu tsattsauran ra'ayi galibi suna buƙatar hakowa ta ramuka don haɗa yadudduka da abubuwan haɗin gwiwa. Wasu na iya yin imani cewa ana buƙatar injin hakowa na musamman saboda canje-canje a cikin kayan da ake buƙata. Yayin da wasu yanayi na iya buƙatar ƙaƙƙarfan ƙwanƙwasa ƙwanƙwasa ko igiya mai sauri, kayan aikin da ke akwai na iya biyan waɗannan buƙatun. Hakazalika, za'a iya cika ta hanyar ramuka tare da kayan aiki ta amfani da daidaitattun kayan aiki da hanyoyin da masana'antu suka tabbatar.

5. Lamination da etching na tagulla:

Lamination foil na jan ƙarfe da matakan etching na gaba sune matakai masu mahimmanci a cikin masana'anta mai sassauƙa. A lokacin waɗannan matakan, ana ɗaure yadudduka na tagulla zuwa ga ma'aunin kuma a zaɓi zaɓi don ƙirƙirar kewayen da ake so. Duk da yake kayan aiki na musamman na iya zama masu fa'ida don samarwa mai girma, daidaitaccen lamination da injunan etching na iya samun kyakkyawan sakamako a cikin ƙananan masana'anta.

6. Haɗin sassa da walda:

Har ila yau, tsarin haɗawa da sayar da kayayyaki ba lallai ba ne su buƙaci kayan aiki na musamman don PCBs masu sassaucin ra'ayi. Ana iya amfani da fasahar hawan dutsen da aka tabbatar (SMT) da dabarun haɗuwa ta hanyar rami zuwa waɗannan allunan. Makullin shine ƙirar da ta dace don ƙirƙira (DFM), yana tabbatar da abubuwan da aka sanya su cikin dabara tare da sassan sassauƙa da yuwuwar abubuwan damuwa a zuciya.

a ƙarshe:

A taƙaice, kuskure ne cewa PCBs masu sassaucin ra'ayi suna buƙatar kayan aikin masana'antu na musamman. Ta hanyar inganta ayyukan masana'antu, a hankali sarrafa kayan sassauƙa, da bin jagororin ƙira, kayan aikin da ake dasu na iya samun nasarar samar da waɗannan allunan kewayawa masu aiki da yawa. Sabili da haka, masana'antu da masu zanen kaya dole suyi aiki tare da ƙwararrun masana'antu waɗanda zasu iya samar da ƙwarewar da ake buƙata a cikin tsarin samarwa. Buɗe yuwuwar PCBs masu ƙarfi ba tare da nauyin kayan aiki na musamman yana ba masana'antu damar yin amfani da fa'idodin su da ƙirƙirar ƙarin sabbin na'urorin lantarki.

Lokacin aikawa: Satumba-19-2023

Baya