Saboda sarkakkiyar tsarinsa da halaye na musamman.samar da katako mai tsayin daka yana buƙatar matakan masana'antu na musamman. A cikin wannan shafin yanar gizon, za mu bincika matakai daban-daban da ke da hannu wajen kera waɗannan ci-gaba masu sassaucin ra'ayi na PCB da kuma kwatanta takamaiman abubuwan da ya kamata a yi la'akari.

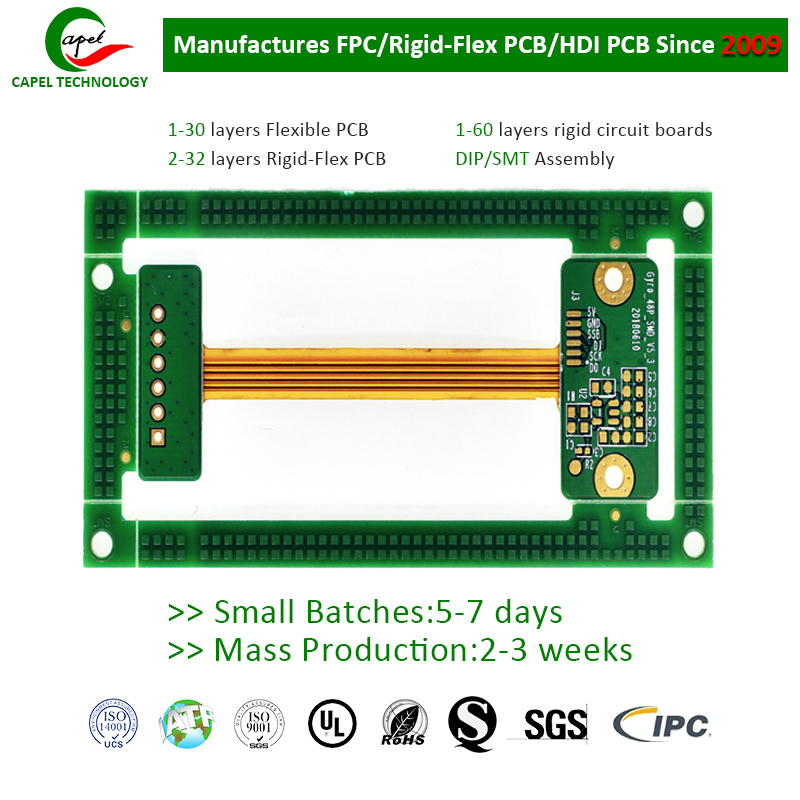

Printed circuit allon (PCBs) sune kashin bayan na'urorin lantarki na zamani. Su ne tushen abubuwan haɗin lantarki masu haɗin gwiwa, suna mai da su muhimmin sashi na yawancin na'urori da muke amfani da su kowace rana. Kamar yadda fasaha ke ci gaba, haka kuma buƙatar samun ƙarin sassauƙa da ƙaƙƙarfan mafita. Wannan ya haifar da haɓakar PCBs masu tsauri, waɗanda ke ba da haɗin kai na musamman na rigidity da sassauci akan allo guda.

Zane katako mai ƙarfi-m

Mataki na farko kuma mafi mahimmanci a cikin tsarin masana'anta mai tsauri shine ƙira. Zana katako mai tsauri yana buƙatar yin la'akari da kyau game da shimfidar allon da'ira gabaɗaya da jeri na sassa. Ya kamata a bayyana wurare masu sassauƙa, radiyoyin lanƙwasa da wuraren ninkawa yayin lokacin ƙira don tabbatar da aikin da ya dace na allon da aka gama.

Abubuwan da ake amfani da su a cikin PCBs masu ƙarfi dole ne a zaɓi su a hankali don saduwa da takamaiman buƙatun aikace-aikacen. Haɗuwa da sassa masu sassauƙa da sassauƙa suna buƙatar cewa kayan da aka zaɓa suna da haɗin kai na musamman da haɓakawa. Ana amfani da maɓalli masu sassauƙa na yau da kullun kamar polyimide da FR4 na bakin ciki, da ƙaƙƙarfan abubuwa kamar FR4 ko ƙarfe.

Stacking Layer da Shirya Substrate don ƙwaƙƙwaran pcb masana'anta

Da zarar zane ya cika, tsarin tarawa na Layer yana farawa. Allolin da'ira bugu masu ƙarfi sun ƙunshi yadudduka da yawa na maɗaukaki masu ƙarfi da sassauƙa waɗanda aka haɗa tare ta amfani da manne na musamman. Wannan haɗin kai yana tabbatar da cewa yadudduka sun kasance cikin tsabta ko da ƙarƙashin yanayi masu ƙalubale kamar girgiza, lankwasawa da canjin zafin jiki.

Mataki na gaba a cikin tsarin masana'antu shine shirya substrate. Wannan ya haɗa da tsaftacewa da kuma kula da saman don tabbatar da mannewa mafi kyau. Tsarin tsaftacewa yana kawar da duk wani gurɓataccen abu wanda zai iya hana tsarin haɗin gwiwa, yayin da jiyya na saman yana haɓaka mannewa tsakanin yadudduka daban-daban. Ana amfani da dabaru irin su maganin plasma ko etching sinadarai don cimma abubuwan da ake so.

Tsarin ƙarfe na ƙarfe da samuwar Layer na ciki don keɓan allunan da'ira mai sassauƙa

Bayan shirya substrate, ci gaba zuwa tsarin ƙirar tagulla. Wannan ya haɗa da ajiye ɗan ƙaramin ƙarfe na jan ƙarfe a kan ma'auni sannan kuma yin aikin hoto don ƙirƙirar ƙirar da'irar da ake so. Ba kamar PCBs na al'ada ba, PCBs masu sassaucin ra'ayi suna buƙatar yin la'akari da sassauƙan sashi yayin tsarin ƙira. Dole ne a ba da kulawa ta musamman don guje wa damuwa mara amfani ko lalacewa ga sassa masu sassauƙa na allon kewayawa.

Da zarar an gama ƙirar tagulla, ƙirar ciki ta fara. A cikin wannan mataki, maɗaukaki masu tsayi da sassauƙa suna daidaitawa kuma an kafa haɗin tsakanin su. Yawanci ana yin wannan ta hanyar amfani da tawul, wanda ke ba da haɗin wutar lantarki tsakanin yadudduka daban-daban. Dole ne a ƙera Vias a hankali don ɗaukar sassaucin hukumar, tabbatar da cewa ba su tsoma baki tare da aikin gaba ɗaya ba.

Lamination da kuma samuwar Layer na waje don masana'anta pcb mai tsauri

Da zarar an kafa Layer na ciki, tsarin lamination ya fara. Wannan ya haɗa da tara nau'ikan ɗaiɗaikun ɗaya da sanya su ga zafi da matsa lamba. Zafi da matsa lamba suna kunna mannewa da haɓaka haɗin kai na yadudduka, ƙirƙirar tsari mai ƙarfi da ɗorewa.

Bayan lamination, tsarin samar da Layer na waje ya fara. Wannan ya haɗa da ajiye wani ɗan ƙaramin ƙarfe na jan ƙarfe a saman saman allon kewayawa, sannan kuma aiwatar da aikin hoto don ƙirƙirar ƙirar kewaye ta ƙarshe. Samar da Layer na waje yana buƙatar daidaito da daidaito don tabbatar da daidaitaccen tsarin kewayawa tare da Layer na ciki.

Drilling, plating da surface jiyya ga m m pcb allon samar

Mataki na gaba a cikin tsarin masana'antu shine hakowa. Wannan ya ƙunshi ramukan hakowa a cikin PCB don ba da damar shigar da abubuwan haɗin gwiwa da haɗa haɗin lantarki. M PCB hakowa yana buƙatar ƙwararrun kayan aiki waɗanda zasu iya ɗaukar kauri daban-daban da allunan kewayawa masu sassauƙa.

Bayan hakowa, ana yin electroplating don haɓaka halayen PCB. Wannan ya haɗa da ajiye wani ɗan ƙaramin ƙarfe (yawanci tagulla) akan bangon ramin da aka haƙa. Ramin da aka ɗora suna ba da ingantaccen hanyar kafa haɗin wutar lantarki tsakanin yadudduka daban-daban.

A ƙarshe, ana yin ƙarewar ƙasa. Wannan ya haɗa da yin amfani da suturar kariya zuwa saman jan karfe da aka fallasa don hana lalata, haɓaka solderability, da haɓaka aikin allo gaba ɗaya. Dangane da takamaiman buƙatun aikace-aikacen, ana samun jiyya daban-daban na saman, kamar HASL, ENIG ko OSP.

Ikon inganci da gwaji don masana'anta mai sassauƙa da bugu

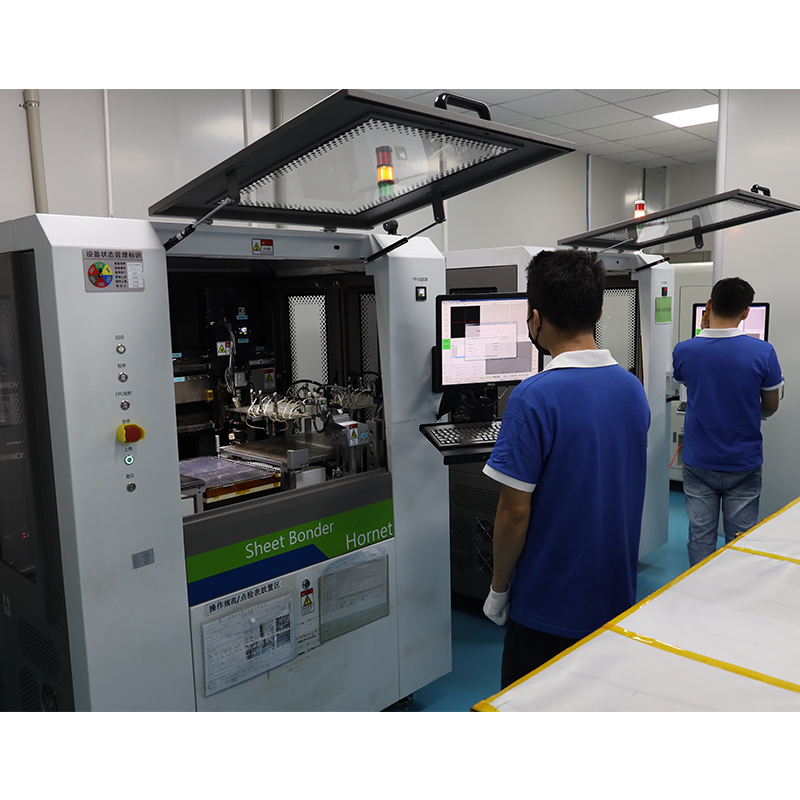

A cikin dukan tsarin masana'antu, ana aiwatar da matakan kula da inganci don tabbatar da mafi girman matakan aminci da aiki. Yi amfani da hanyoyin gwaji na ci gaba kamar duban gani mai sarrafa kansa (AOI), duban X-ray da gwajin lantarki don gano duk wata lahani ko al'amurra a cikin allon da'irar da aka gama. Bugu da kari, ana yin gwajin muhalli mai tsauri da aminci don tabbatar da cewa PCBs masu sassauƙa na iya jure yanayin ƙalubale.

Don taƙaitawa

Samar da alluna masu tsauri ba ya buƙatar matakan masana'antu na musamman. Siffar hadaddun tsari da halaye na musamman na waɗannan allunan da'irar ci-gaba suna buƙatar la'akari da ƙira a hankali, ainihin zaɓin kayan aiki da matakan ƙira na musamman. Ta bin waɗannan ƙwararrun matakai na masana'antu, masana'antun na'urorin lantarki za su iya amfani da cikakkiyar damar PCBs masu ƙarfi da kuma kawo sabbin dama don sabbin na'urori masu sassauƙa da ƙaƙƙarfan na'urorin lantarki.

Lokacin aikawa: Satumba 18-2023

Baya