Mu zurfafa zurfafa cikin duniyarm-launi allunan.

A fagen kera na'urorin lantarki da ke ci gaba da samun ci gaba, sabbin fasahohi na bullowa, suna haifar da ci gaba da na'urori masu inganci. Fasahar PCB mai ƙarfi-sauƙaƙa ce irin wannan bidi'a wacce ta sami kulawa sosai a cikin 'yan shekarun nan. Wannan cikakken jagorar yana nufin ƙaddamar da ra'ayi na PCB mai tsauri da kuma bayyana halayensa, fa'idodinsa, aikace-aikacensa, hanyoyin masana'antu da yuwuwar ci gaban gaba.

Fahimtar Rigid-Flex PCBs

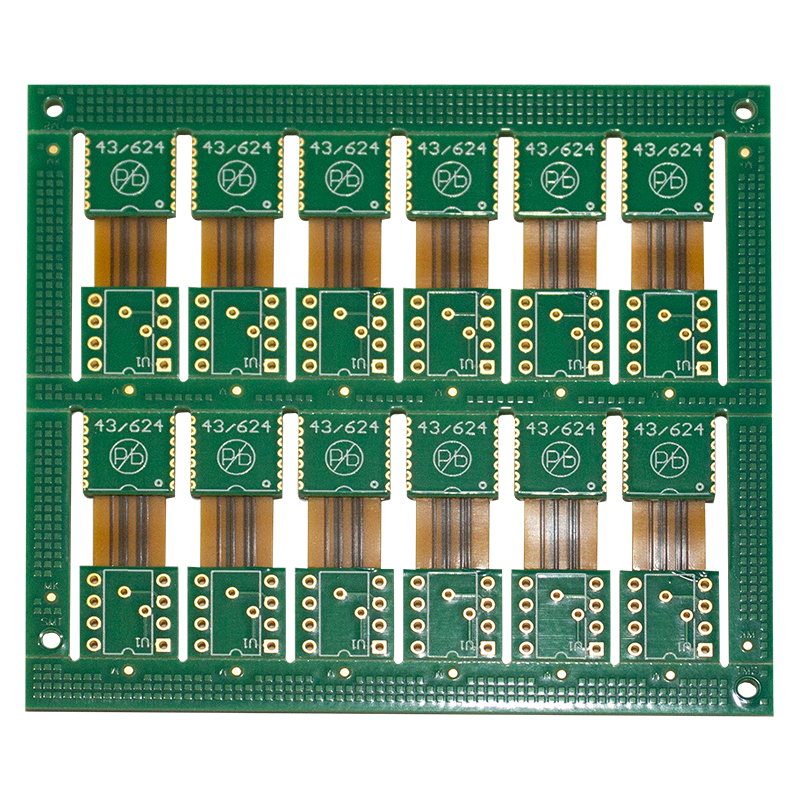

Alƙalai masu sassauƙa, wanda kuma aka sani da allon kewayawa mai sassauƙa ko tsayayyen allo, suna haɗa kaddarorin kwalayen da'ira masu ƙarfi (PCBs) da sassauƙan da'irori zuwa raka'a ɗaya. Yana haɗu da fa'idodin madaidaitan madauri da sassauƙa, yana ba da damar ƙira masu rikitarwa da daidaitawa mai girma uku waɗanda ba zai yiwu ba tare da tsayayyen PCB na gargajiya. Wannan tsari na musamman ya ƙunshi nau'i-nau'i da yawa na kayan kewayawa masu sassauƙa waɗanda aka lulluɓe tsakanin madaidaitan yadudduka. Sakamako shine babban aiki, nauyi mai nauyi da ɗorewa wanda zai iya jure rikitattun matsalolin inji, matsanancin zafi da girgiza.

Babban fasali da fa'idodin alluna masu ƙarfi

PCBs masu sassaucin ra'ayi suna ba da fa'idodi da yawa akan ƙirar PCB na gargajiya. Na farko, sassaucin su yana ba da damar haɗa kai cikin na'urori marasa tsari, rage ƙayyadaddun sararin samaniya da haɓaka amincin samfur gaba ɗaya. Suna ba da tanadin sararin samaniya mai mahimmanci, ƙyale injiniyoyi su ƙirƙira ƙarancin lantarki, ƙananan nauyi. Bugu da ƙari, kawar da masu haɗawa da manyan wayoyi yana sauƙaƙe tsarin taro kuma yana rage haɗarin yuwuwar maki gazawar.

PCBs masu sassaucin ra'ayi kuma suna nuna kyakkyawan juriya ga abubuwan muhalli kamar danshi, sinadarai, da canjin yanayi. Ƙarfinsu na jure yanayin yanayi ya sa su dace don aikace-aikace a cikin masana'antu masu buƙata kamar sararin samaniya, na'urorin likitanci da na'urorin lantarki na mota. Bugu da ƙari, babban amincin su da dorewa yana taimakawa haɓaka aiki, rage farashin kulawa da tsawaita yanayin rayuwar samfur.

Aikace-aikace na m-flex board

Ana amfani da PCBs masu sassaucin ra'ayi a masana'antu da yawa saboda dacewarsu da daidaitawa. A cikin sashin sararin samaniya, ana amfani da su a cikin tsarin jiragen sama, tauraron dan adam da jirage marasa matuki, inda ƙarancin ƙira, ƙira mai sauƙi da juriya ga matsanancin yanayi ke da mahimmanci. A cikin masana'antar likita, ana amfani da su a cikin na'urorin likitanci, na'urorin lantarki da za a iya dasa su, da na'urori masu auna sigina, suna ba da gudummawa ga ci gaban fasahar kiwon lafiya. Hakanan ana amfani da PCBs masu ƙarfi a cikin kayan lantarki na mabukaci, musamman wayowin komai da ruwan, wearables da allunan, inda haɓaka sararin samaniya da amincin ke da mahimmanci.

A cikin filin kera motoci, PCBs masu sassaucin ra'ayi suna taka muhimmiyar rawa a tsarin taimakon direba na ci-gaba (ADAS), tsarin infotainment, da na'urorin sarrafa lantarki (ECUs). Ƙarfin su na jure wa girgizawa da yanayin zafi ya sa su dace don aikace-aikacen mota, tabbatar da ingantaccen aiki na tsarin mahimmanci. Bugu da kari, kayan aikin masana'antu, gami da na'ura mai ba da hanya tsakanin hanyoyin sadarwa, injina, da tsarin rarraba wutar lantarki, suna amfana daga sassaucin PCBs masu ƙarfi don yin aiki da inganci da dogaro har ma a cikin mahalli masu ƙalubale.

Tsari-tsarin masana'anta na hukumar

Kera PCBs masu sassaucin ra'ayi ya ƙunshi jerin matakai masu mahimmanci don tabbatar da samfurin ƙarshe ya cika ƙayyadaddun da ake buƙata. Waɗannan matakan yawanci sun haɗa da ƙira da shimfidawa, zaɓin kayan aiki, hakowa, plating, hoto, lamination, etching, aikace-aikacen abin rufe fuska mai solder, gwaji da dubawa na ƙarshe.

Tsarin tsarawa da tsararru yana mai da hankali kan ƙirƙirar ingantaccen tsarin kewayawa wanda ke la'akari da buƙatun inji da lantarki na aikace-aikacen da aka yi niyya. Zaɓin kayan abu yana da mahimmanci yayin da zaɓin ƙasa da mannewa yana rinjayar gaba ɗaya sassauci, kwanciyar hankali da dorewa na samfurin ƙarshe. Hakowa da sakawa matakai ne masu mahimmanci waɗanda ke da hannu wajen ƙirƙirar hanyoyin da suka dace da hanyoyin gudanarwa.

A yayin aiwatar da hoto, ana amfani da Layer na photoresisist kuma ana zaɓin fallasa, ƙirƙirar ƙayyadaddun tsarin kewayawa. Na gaba ya zo lamination, inda yadudduka na sassauƙan kayan da'ira da tsayayyen allo ke haɗuwa tare ta amfani da zafi da matsa lamba. Etching yana cire jan ƙarfe maras buƙata don samar da alamun da'irar da ake buƙata, yayin da ake amfani da abin rufe fuska don kare tagulla da aka fallasa da ƙara rufi.

Gwaji da dubawa na ƙarshe sun tabbatar da cewa ƙera kwalaye masu tsattsauran ra'ayi sun cika ƙa'idodin ingancin da ake buƙata. Ana amfani da hanyoyi daban-daban na gwaji ciki har da gwajin lantarki, dubawa na gani da kuma hawan zafi don tabbatar da aiki da aminci.

Kwamitin tsattsauran ra'ayi na gaba

Ana sa ran fannin PCBs masu sassaucin ra'ayi zai iya samun gagarumin ci gaba a cikin shekaru masu zuwa. Fasaha masu tasowa kamar 5G, Intanet na Abubuwa (IoT) da na'urori masu sawa za su ci gaba da fitar da buƙatun na'urorin lantarki masu sassauƙa. Ƙoƙarin bincike da haɓaka suna mayar da hankali kan haɓaka hanyoyin masana'antu, rage farashi da haɓaka ayyukan PCBs masu ƙarfi. Wannan zai ba da damar ƙarin ƙira masu rikitarwa da sassauƙa, buɗe ƙofar zuwa aikace-aikacen sabbin abubuwa da yuwuwar.

a takaice

Fasahar PCB mai ƙarfi mai ƙarfi tana ba da haɗin kai na musamman na sassauƙa da dorewa, yana taimakawa haɓaka abin dogaro sosai da na'urorin lantarki masu adana sarari. Yawancin fasalulluka da fa'idodinsa sun sa ya dace don masana'antu daban-daban, daga sararin samaniya zuwa kiwon lafiya, mota zuwa na'urorin lantarki masu amfani. Yayin da fasaha ke ci gaba da haɓakawa, PCBs masu sassaucin ra'ayi babu shakka za su taka muhimmiyar rawa wajen haɓaka ƙima a fagen masana'antar lantarki.

Lokacin aikawa: Satumba-15-2023

Baya