Gabatarwa

A cikin wannan shafin yanar gizon, za mu tattauna ingantattun dabaru da mafi kyawun ayyuka na masana'antu don hana lalata PCB mai tsauri, ta haka ne ke kare na'urorin ku na lantarki daga gazawa.

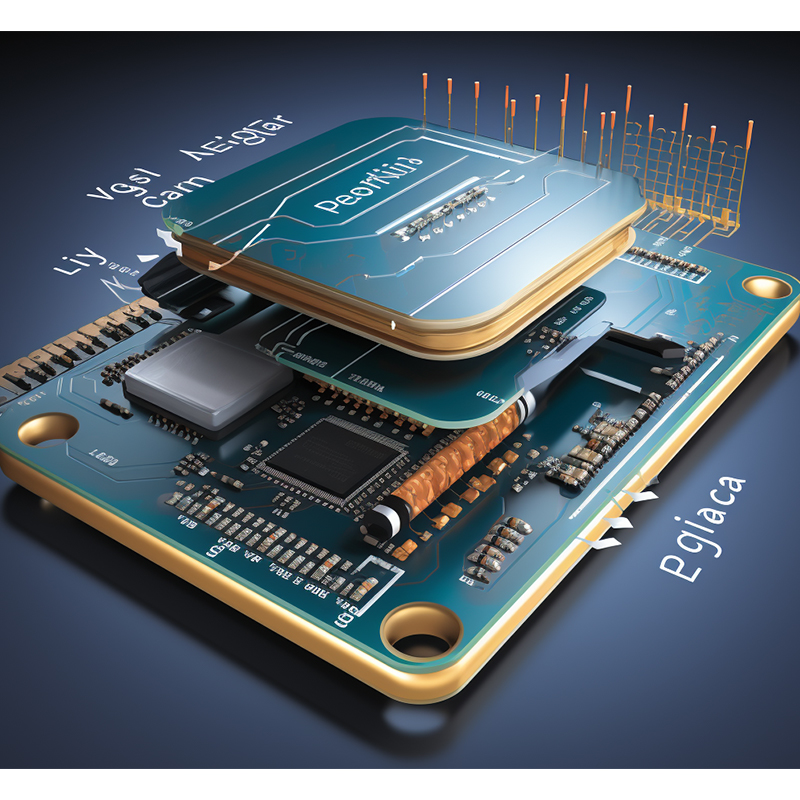

Delamination wani lamari ne mai mahimmanci wanda sau da yawa yakan addabi allunan da'ira mai ƙarfi (PCBs) yayin rayuwarsu ta sabis. Wannan al'amari yana nufin rabuwar yadudduka a cikin PCB, wanda ke haifar da haɗin kai mai rauni da rashin gazawar bangaren. A matsayin masana'anta ko mai ƙira, yana da mahimmanci don fahimtar abubuwan da ke haifar da lalata kuma ɗaukar matakan kariya don tabbatar da kwanciyar hankali na dogon lokaci da amincin PCB ɗin ku.

I. Fahimtar delamination a cikin PCB mai ƙarfi

Delamination yana faruwa ta hanyoyi daban-daban yayin masana'antu, taro, da matakan kulawa na PCBs masu sassaucin ra'ayi. Damuwar zafi, shayar da danshi da zaɓin kayan da bai dace ba sune abubuwan gama gari na delamination. Gano da fahimtar waɗannan dalilai yana da mahimmanci don haɓaka dabarun rigakafi masu inganci.

1. Rashin damuwa: madaidaicin yaduwar yanayin zafi (CTE) tsakanin kayan daban-daban na iya haifar da matsanancin damuwa yayin hawan keke, yana haifar da bata lokaci.Lokacin da PCB ya sami canjin yanayin zafi, yaduddukan suna faɗaɗa kuma suna yin kwangila a farashi daban-daban, suna haifar da tashin hankali a cikin haɗin gwiwa tsakanin su.

2. Danshi sha: m m PCB ne sau da yawa fallasa zuwa high zafi yanayi da kuma sauƙi sha danshi.Kwayoyin ruwa na iya shiga saman allon ta hanyar microcracks, voids, ko wuraren buɗe ido mara kyau, haifar da faɗaɗa cikin gida, kumburi, kuma a ƙarshe delamination.

3. Zaɓin Kayan abu: Yin la'akari da hankali na kayan abu yana da mahimmanci don hana lalata.Yana da mahimmanci don zaɓar laminate da ya dace, mannewa da jiyya na saman don samar da ƙarancin ɗanɗano da kwanciyar hankali na zafi mai kyau.

2. Dabarun hana delamination

Yanzu da muka fahimci dalilin da yasa, bari mu bincika mahimman dabaru don hana lalatawar PCB mai ƙarfi:

1. Abubuwan da suka dace da ƙira:

a) Rage kaurin tagulla:Yawan kaurin tagulla yana haifar da damuwa yayin hawan keken zafi. Don haka, yin amfani da mafi ƙarancin kauri da ake buƙata na jan ƙarfe yana ƙaruwa da sassaucin PCB kuma yana rage haɗarin delamination.

b) Daidaitaccen tsarin Layer:Ƙoƙari don rarraba nau'ikan yadudduka na jan karfe a cikin sassauƙa da sassauƙa na PCB. Daidaitaccen ma'auni yana taimakawa wajen haɓaka haɓakar yanayin zafi mai ma'ana da raguwa, yana rage yuwuwar lalatawa.

c) Hakuri masu sarrafawa:Aiwatar da juriya mai sarrafawa akan girman rami, ta diamita da faɗin gano don tabbatar da cewa an rarraba damuwa yayin canje-canjen zafi a ko'ina cikin PCB.

d) Fillets da fillet:Fillets suna rage abubuwan tattarawar damuwa, suna taimakawa cimma sauye-sauyen lanƙwasa mai santsi da rage yuwuwar delamination.

2. Zaɓin kayan aiki:

a) Babban Tg Laminates:Zaɓi laminates tare da mafi girman yanayin canjin gilashin (Tg) yayin da suke ba da mafi kyawun juriya na zafin jiki, rage rashin daidaituwar CTE tsakanin kayan, da kuma rage matakan hawan keke na thermal rarrabuwar haɗari.

b) Ƙananan kayan CTE:Zaɓi kayan da ke da ƙananan ƙimar CTE don rage rashin daidaituwa na haɓakar zafi tsakanin yadudduka daban-daban, don haka rage damuwa da haɓaka amincin gabaɗayan PCBs masu sassaucin ra'ayi.

c) Abubuwan da ba su da ɗanshi:Zaɓi kayan da ke da ƙarancin ƙarancin ɗanɗano don rage haɗarin delamination saboda ɗaukar danshi. Yi la'akari da yin amfani da ƙwararrun sutura ko masu rufewa don kare wuraren da ke da rauni na PCB daga kutsawa danshi.

3. Ƙarfafan Ayyukan Ƙarfafawa:

a) Tasirin Sarrafa:Aiwatar da tsarin masana'anta mai sarrafawa don rage yawan sauye-sauyen damuwa akan PCB yayin aiki, ta haka zai rage haɗarin delamination.

b) Adana da Kulawa da kyau:Ajiye da kuma sarrafa PCBs a cikin yanayi mai sarrafawa tare da sarrafa zafi don hana ɗaukar danshi da abubuwan da suka shafi lalata.

c) Gwaji da dubawa:Ana gudanar da tsauraran gwaje-gwaje da hanyoyin dubawa don gano duk wata lahani da ke iya haifar da lalata. Aiwatar da dabarun gwaji marasa lahani kamar hawan keke na zafi, microsectioning, da duban abubuwan gani na gani na iya taimakawa gano ɓoyayyun ɓangarorin da wuri.

Kammalawa

Hana lalata PCBs masu ƙarfi yana da mahimmanci don tabbatar da tsawon rayuwarsu da ingantaccen aiki. Kuna iya rage haɗarin lalata ta hanyar fahimtar abubuwan da ke haifar da ɗaukar matakan da suka dace yayin ƙira, zaɓin kayan aiki, da masana'anta.Aiwatar da ingantaccen tsarin kula da zafi, amfani da kayan da ke da kyawawan kaddarorin, yin amfani da ingantattun ayyukan masana'antu, da gudanar da cikakken gwaji na iya haɓaka inganci da amincin PCBs masu ƙarfi. Ta bin waɗannan dabarun da kuma ci gaba da sabuntawa kan sabbin ci gaba a cikin kayan aiki da fasahar kere-kere, za ku iya tabbatar da nasarar ci gaban PCBs masu dorewa da dogaro waɗanda ke ba da gudummawa ga kwanciyar hankali da amincin na'urorin lantarki.

Lokacin aikawa: Satumba-20-2023

Baya