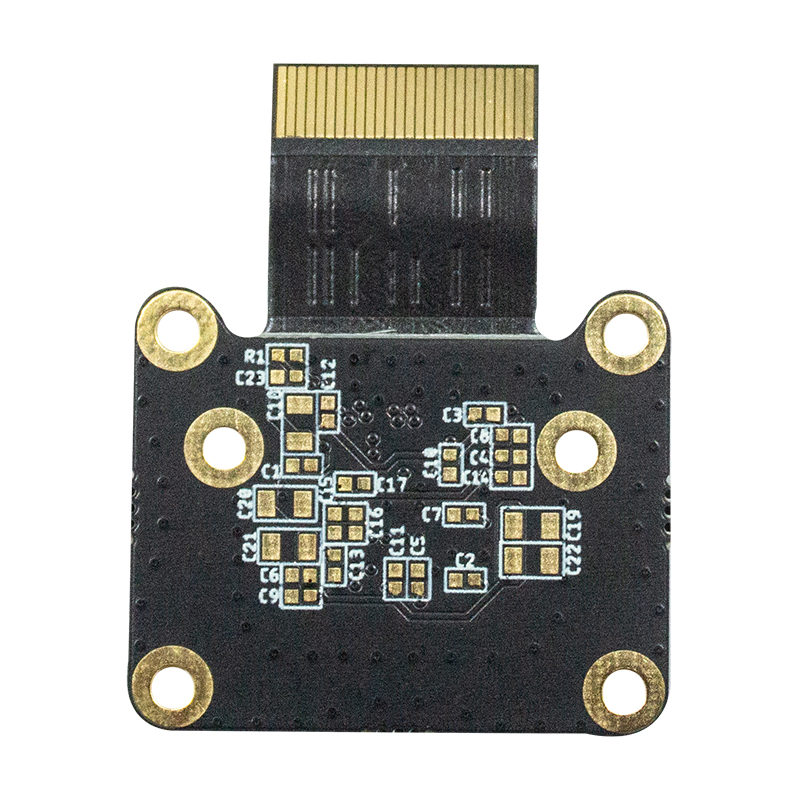

PCB (Printed Circuit Board) wani muhimmin sashi ne a cikin samfuran lantarki na zamani, yana ba da damar haɗin kai da ayyukan kayan aikin lantarki daban-daban. Tsarin samarwa na PCB ya ƙunshi matakai masu mahimmanci da yawa, ɗaya daga cikinsu shine saka tagulla akan ma'auni. Wannan labarin za mu dubi hanyoyin da ake ajiye tagulla a kan abubuwan da ake amfani da su na PCB yayin aikin samarwa, da kuma zurfafa cikin dabaru daban-daban da ake amfani da su, kamar plating maras amfani da tagulla da lantarki.

1.Electroless jan karfe plating: bayanin, tsarin sinadaran, abũbuwan amfãni, rashin amfani da yankunan aikace-aikace.

Don gane abin da electroless plating jan karfe, yana da muhimmanci a fahimci yadda yake aiki. Ba kamar electrodeposition ba, wanda ya dogara da wutar lantarki don ajiyar ƙarfe, plating maras amfani da tagulla tsari ne na autophoretic. Ya haɗa da rage sarrafa sinadari na ions jan ƙarfe a kan wani abu, wanda ya haifar da ƙayyadaddun nau'in yumɓu mai kama da tagulla.

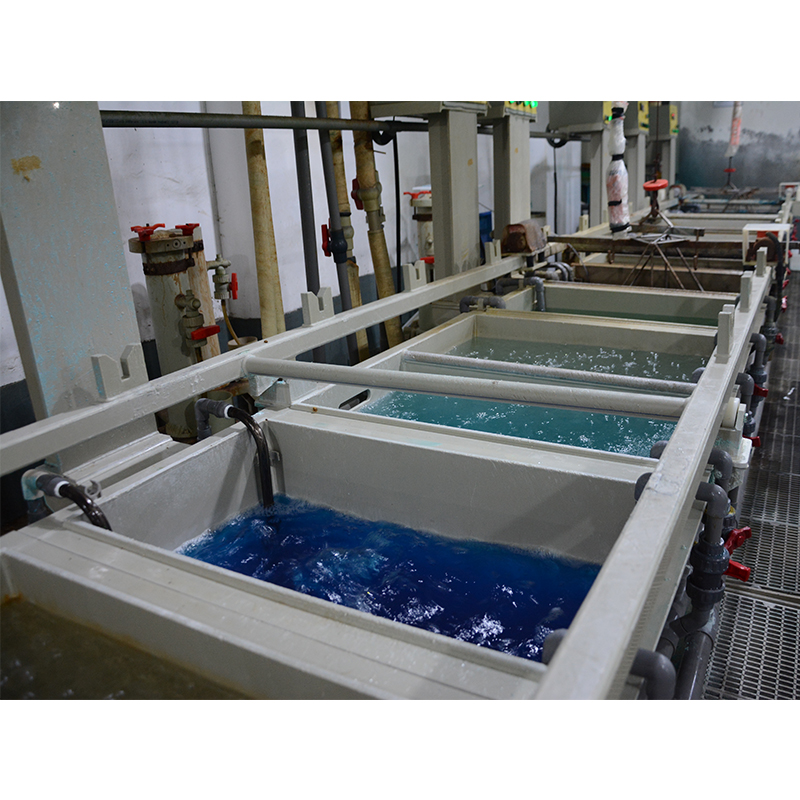

Tsaftace substrate:Tsaftace daki-daki don cire duk wani gurɓataccen abu ko oxides wanda zai iya hana mannewa. Kunnawa: Maganin kunnawa mai ɗauke da ƙarfe mai mahimmanci kamar palladium ko platinum ana amfani dashi don fara aikin lantarki. Wannan bayani yana sauƙaƙe ajiyar tagulla akan substrate.

Nutsa cikin maganin plating:A nutsar da abin da aka kunna a cikin maganin plating tagulla mara amfani. Maganin plating yana ƙunshe da ions jan ƙarfe, rage yawan wakilai da ƙari daban-daban waɗanda ke sarrafa tsarin sakawa.

Tsarin Electrolating:Wakilin ragewa a cikin maganin electroplating da sinadarai yana rage ions jan ƙarfe zuwa ƙarfe na jan karfe. Waɗannan ƙwayoyin zarra daga nan suna haɗi zuwa saman da aka kunna, suna samar da madaidaicin Layer na jan karfe.

Kurkura da bushe:Da zarar an sami kaurin jan ƙarfe da ake so, za a cire abin da ake buƙata daga tankin plating kuma a wanke shi sosai don cire duk wasu sinadarai. Busasshen da aka yi da shi kafin a ci gaba da aiki. Tsarin gyare-gyaren jan ƙarfe na sinadarai Tsarin sinadari na platin jan ƙarfe mara igiyar lantarki ya haɗa da sake maimaita amsawa tsakanin ions jan ƙarfe da rage abubuwa. Matakai masu mahimmanci a cikin tsari sun haɗa da: Kunnawa: Amfani da kayan aikin ƙarfe masu daraja kamar palladium ko platinum don kunna saman ƙasa. Mai kara kuzari yana samar da wuraren da ake buƙata don haɗin sinadarai na ions jan ƙarfe.

Wakilin Ragewa:Wakilin ragewa a cikin maganin plating (yawanci formaldehyde ko sodium hypophosphite) yana farawa da ragi. Wadannan reagents suna ba da gudummawar electrons ga ions jan ƙarfe, suna mai da su zuwa ƙwayoyin ƙarfe na ƙarfe.

Maganganun kaikayi:Atom ɗin jan ƙarfe da aka samar ta hanyar raguwar amsawa suna amsawa tare da mai kara kuzari a saman ma'aunin don samar da nau'in tagulla iri ɗaya. Halin ya ci gaba ba tare da buƙatar buƙatar halin yanzu da ake amfani da shi ba, yana mai da shi "plating electroless."

Sarrafa adadin ajiya:Abun da ke ciki da ƙaddamar da bayani na plating, da kuma sigogi na tsari irin su zafin jiki da pH, ana sarrafa su a hankali don tabbatar da cewa an sarrafa adadin ajiya da kuma daidaituwa.

Amfanin Uniformity na jan ƙarfe mara igiyar waya:Platin jan karfe mara amfani da wutar lantarki yana da ingantacciyar daidaituwa, yana tabbatar da kauri iri ɗaya a cikin hadaddun sifofi da wuraren da ba a kwance ba. Coating Conformal: Wannan tsari yana ba da suturar da ta dace wacce ke manne da kyau ga abubuwan da ba su dace ba kamar PCBs. Kyakkyawar mannewa: Platin jan ƙarfe mara amfani da lantarki yana da ƙarfi mannewa ga abubuwa iri-iri, gami da robobi, yumbu da ƙarfe. Plating Selective: Plating na jan ƙarfe mara amfani da wutar lantarki na iya zaɓin saka tagulla akan takamaiman wuraren da ake amfani da shi ta amfani da dabarun rufe fuska. Karancin Kuɗi: Idan aka kwatanta da sauran hanyoyin, platin jan ƙarfe mara amfani da wutar lantarki zaɓi ne mai tsada don saka tagulla a kan ma'auni.

Lalacewar tagulla maras amfani da wutan lantarki Sannun rahusa ƙimar ajiya:Idan aka kwatanta da hanyoyin lantarki, plating mara amfani da tagulla yawanci yana da ƙarancin ajiya a hankali, wanda zai iya ƙara tsawon lokacin aikin lantarki gabaɗaya. Kauri mai iyaka: Platin jan ƙarfe mara amfani da wutar lantarki gabaɗaya ya dace da saka siraren jan ƙarfe na bakin ciki don haka bai dace da aikace-aikacen da ke buƙatar kauri ba. Haɗuwa: Tsarin yana buƙatar kulawa da hankali na sigogi daban-daban, gami da zafin jiki, pH da ƙididdigar sinadarai, yana sa ya fi rikitarwa don aiwatarwa fiye da sauran hanyoyin lantarki. Gudanar da Sharar gida: Zubar da hanyoyin zubar da shara masu ɗauke da ƙarfe masu nauyi na iya haifar da ƙalubalen muhalli kuma yana buƙatar kulawa da hankali.

Wuraren aikace-aikace na PCB plating na jan ƙarfe mara amfani:Ana amfani da platin jan ƙarfe mara amfani da wutar lantarki sosai wajen kera allunan da'ira da aka buga (PCBs) don samar da alamun da za a iya bi da su kuma a lika su ta ramuka. Masana'antar Semiconductor: Suna taka muhimmiyar rawa wajen samar da na'urori masu kama da juna kamar masu ɗaukar guntu da firam ɗin gubar. Masana'antun kera motoci da na sararin samaniya: Ana amfani da platin jan ƙarfe mara amfani da wutar lantarki don yin haɗin wutar lantarki, masu sauyawa da kayan aikin lantarki masu inganci. Rufin Ado da Aiki: Ana iya amfani da platin jan ƙarfe mara amfani da wutar lantarki don ƙirƙirar ƙayyadaddun kayan ado akan nau'ikan nau'ikan nau'ikan nau'ikan nau'ikan nau'ikan nau'ikan nau'ikan nau'ikan nau'ikan nau'ikan nau'ikan nau'ikan nau'ikan nau'ikan nau'ikan nau'ikan nau'ikan nau'ikan nau'ikan nau'ikan nau'ikan nau'ikan nau'ikan nau'ikan nau'ikan nau'ikan nau'ikan nau'ikan nau'ikan nau'ikan nau'ikan nau'ikan nau'ikan nau'ikan nau'ikan nau'ikan nau'ikan nau'ikan nau'ikan nau'ikan nau'ikan nau'ikan nau'ikan nau'ikan nau'ikan nau'ikan nau'ikan nau'ikan nau'ikan nau'ikan nau'ikan nau'ikan nau'ikan nau'ikan nau'ikan iri) suna da nau'ikan iri-iri na kayan ado da kayan ado da kayan aiki waɗanda aka yi amfani da su don ƙirƙirar kayan ado na kayan ado don ƙirƙirar ƙayyadaddun kayan ado, gami da kariya ta lalata da ingantaccen ƙarfin lantarki.

2.Copper plating a kan PCB substrate

Sanya tagulla akan abubuwan PCB muhimmin mataki ne a cikin tsarin masana'anta da aka buga (PCB). An fi amfani da Copper azaman kayan lantarki saboda kyawawan halayensa na lantarki da kyakkyawar mannewa ga ma'auni. Tsarin gyare-gyaren tagulla ya haɗa da ajiye bakin karfe na jan karfe a saman PCB don ƙirƙirar hanyoyin gudanarwa don siginar lantarki.

Tsarin platin tagulla akan abubuwan PCB yawanci ya haɗa da matakai masu zuwa: Shirye-shiryen saman:

Tsaftace ma'aunin PCB sosai don cire duk wani gurɓataccen abu, oxides ko ƙazanta waɗanda zasu iya hana mannewa kuma suna shafar ingancin plating.

Shirye-shiryen Electrolyte:

Shirya maganin electrolyte mai dauke da jan karfe sulfate a matsayin tushen ions jan karfe. Electrolyte kuma yana ƙunshe da ƙari waɗanda ke sarrafa tsarin plating, kamar masu daidaitawa, masu haske, da masu daidaita pH.

Electrodeposition:

A tsoma da shirin PCB substrate a cikin electrolyte bayani da kuma amfani kai tsaye halin yanzu. PCB yana aiki azaman haɗin cathode, yayin da anode na jan karfe shima yana cikin maganin. A halin yanzu yana sa ions jan ƙarfe a cikin electrolyte ya ragu kuma a ajiye su a saman PCB.

Sarrafa sigogin plating:

Ana sarrafa sigogi daban-daban a hankali yayin aikin plating, gami da yawa na yanzu, zazzabi, pH, motsawa da lokacin plating. Waɗannan sigogi suna taimakawa tabbatar da daidaito iri ɗaya, mannewa, da kauri da ake so na layin jan karfe.

Maganin bayan-plating:

Da zarar an kai kaurin jan ƙarfe da ake so, ana cire PCB daga wankan plating kuma a wanke don cire duk wani maganin electrolyte da ya rage. Ana iya yin ƙarin jiyya bayan-plating, kamar tsaftacewar ƙasa da wucewa, don haɓaka inganci da kwanciyar hankali na platin jan karfe.

Abubuwan da ke shafar ingancin electroplating:

Shirye-shiryen saman:

Daidaitaccen tsaftacewa da kuma shirye-shiryen saman PCB yana da mahimmanci don cire duk wani gurɓataccen abu ko yadudduka na oxide da tabbatar da kyakkyawan mannewa na platin jan karfe. Ƙirƙirar maganin plating:

Abubuwan da ke tattare da maganin electrolyte, ciki har da ƙaddamar da sulfate na jan karfe da ƙari, zai shafi ingancin plating. Ya kamata a sarrafa abun da ke ciki na wanka a hankali don cimma abubuwan da ake so.

Ma'auni:

Sarrafa sigogin plating kamar yawa na yanzu, zafin jiki, pH, motsawa da lokacin plating yana da mahimmanci don tabbatar da daidaituwa iri ɗaya, mannewa da kauri na layin jan karfe.

Abun da ke ƙasa:

Nau'in da ingancin PCB substrate abu zai shafi mannewa da ingancin tagulla plating. Daban-daban kayan substrate na iya buƙatar gyare-gyare ga tsarin plating don kyakkyawan sakamako.

Taushin saman:

Ƙunƙarar saman na'ura mai kwakwalwa ta PCB zai shafi mannewa da ingancin Layer plating na jan karfe. Shirye-shiryen da ya dace da kuma kula da sigogi na plating yana taimakawa rage matsalolin da ke da alaƙa

Amfanin PCB substrate tagulla plating:

Kyakkyawan ingancin wutar lantarki:

An san Copper don haɓakar wutar lantarki mai girma, yana mai da shi kyakkyawan zaɓi don kayan kwalliyar PCB. Wannan yana tabbatar da ingantaccen kuma abin dogaro na siginar lantarki. Kyakkyawan mannewa:

Copper yana nuna kyakkyawar mannewa ga nau'ikan nau'ikan nau'ikan nau'ikan nau'ikan nau'ikan nau'ikan nau'ikan nau'ikan nau'ikan nau'ikan nau'ikan nau'ikan nau'ikan nau'ikan nau'ikan nau'ikan nau'ikan nau'ikan nau'ikan nau'ikan nau'ikan nau'ikan nau'ikan nau'ikan nau'ikan nau'ikan nau'ikan nau'ikan nau'ikan nau'ikan nau'ikan nau'ikan jan ƙarfe na jan ƙarfe yana nuna kyakkyawan mannewa ga nau'ikan nau'ikan nau'ikan nau'ikan nau'ikan nau'ikan nau'ikan nau'ikan nau'ikan nau'ikan nau'ikan nau'ikan nau'ikan nau'ikan nau'ikan nau'ikan jan ƙarfe na Copper yana nuna kyakkyawan mannewa ga nau'ikan nau'ikan nau'ikan nau'ikan nau'ikan nau'ikan nau'ikan nau'ikan nau'ikan nau'ikan nau'ikan nau'ikan nau'ikan nau'ikan nau'ikan nau'ikan nau'ikan nau'ikan nau'ikan nau'ikan nau'ikan jan ƙarfe na jan ƙarfe yana nuna kyakkyawan mannewa mai kyau da mannewa da ƙari, yana tabbatar da haɗin gwiwa mai ƙarfi da tsayin daka tsakanin sutura da ma'auni.

Juriya na Lalata:

Copper yana da kyakkyawan juriya na lalata, yana kare abubuwan da ke cikin PCB da kuma tabbatar da dogaro na dogon lokaci. Solderability: Copper plating yana samar da farfajiyar da ta dace don siyarwa, yana sauƙaƙa haɗa kayan aikin lantarki yayin haɗuwa.

Ingantacciyar zubar da zafi:

Copper ne mai kyau thermal madugu, kunna ingantaccen zafi na PCBs. Wannan yana da mahimmanci musamman ga aikace-aikacen wutar lantarki.

Iyakoki da ƙalubalen jan ƙarfe electroplating:

Kula da kauri:

Samun madaidaicin iko akan kauri mai kauri na jan ƙarfe na iya zama ƙalubale, musamman a wurare masu rikitarwa ko matsatsin wurare akan PCB. Uniformity: Tabbatar da shigar da tagulla iri ɗaya a kan gabaɗayan saman PCB, gami da wuraren da ba a kwance ba da kyawawan siffofi, na iya zama da wahala.

Farashin:

Electroplating jan karfe na iya zama mafi tsada idan aka kwatanta da sauran hanyoyin electroplating saboda farashin plating tanki sunadarai, kayan aiki, da kuma kiyayewa.

Gudanar da Sharar gida:

Zubar da hanyoyin da ake kashewa da kuma kula da ruwan sha mai ɗauke da ions jan ƙarfe da sauran sinadarai na buƙatar hanyoyin sarrafa sharar da suka dace don rage tasirin muhalli.

Matsalolin Tsari:

Electrolating jan ƙarfe ya ƙunshi sigogi da yawa waɗanda ke buƙatar kulawa da hankali, suna buƙatar ƙwararrun ilimi da rikitattun saitin plating.

3.Comparison tsakanin electroless jan karfe plating da electroplating

Bambance-bambancen aiki da inganci:

Akwai bambance-bambance da yawa a cikin aiki da inganci tsakanin platin jan ƙarfe mara amfani da lantarki a cikin waɗannan abubuwan:

Plating na jan ƙarfe mara amfani da wutar lantarki tsari ne na saka sinadari wanda baya buƙatar tushen wutar lantarki na waje, yayin da lantarki ya haɗa da yin amfani da kai tsaye don saka wani Layer na jan karfe. Wannan bambance-bambancen hanyoyin ajiya na iya haifar da bambance-bambancen ingancin sutura.

Plating jan ƙarfe mara amfani da wutar lantarki gabaɗaya yana ba da ƙarin ajiya iri ɗaya a kan gabaɗayan saman ƙasa, gami da wuraren da ba a kwance ba da kyawawan siffofi. Wannan saboda plating yana faruwa a ko'ina a duk saman ko da kuwa yanayin su. Electroplating, a daya bangaren, na iya samun matsala wajen cimma daidaitattun bayanai a cikin hadaddun wurare ko da wuya a isa.

Platin jan karfe mara amfani da wutar lantarki zai iya cimma rabo mafi girma (matsayin tsayin fasalin zuwa faɗin) fiye da na'urar lantarki. Wannan ya sa ya dace da aikace-aikacen da ke buƙatar babban kaddarorin rabo, kamar ramuka a cikin PCBs.

Platin jan karfe mara amfani da wutar lantarki gabaɗaya yana samar da ƙasa mai santsi, mai laushi fiye da lantarki.

Electroplating na iya haifar da rashin daidaituwa, m ko rashin ajiya a wani lokaci saboda canje-canje a yawan yawan yanzu da yanayin wanka. Ingancin haɗin da ke tsakanin Layer plating ɗin tagulla da maƙallan na iya bambanta tsakanin platin jan ƙarfe mara amfani da lantarki.

Bakin karfe plating gabaɗaya yana samar da mafi kyawun mannewa saboda tsarin haɗin sinadarai na jan ƙarfe mara igiyar ruwa zuwa ma'auni. Plating ya dogara da haɗin kai na inji da na lantarki, wanda zai iya haifar da raunin shaidu a wasu lokuta.

Kwatanta Farashin:

Chemical Deposition vs. Electroplating: A lokacin da kwatanta halin kaka na electroless jan karfe plating da electroplating, da dama dalilai ya kamata a yi la'akari:

Farashin sinadarai:

Platin ƙarfe maras amfani da wutar lantarki gabaɗaya yana buƙatar ƙarin sinadarai masu tsada idan aka kwatanta da lantarki. Sinadaran da ake amfani da su a cikin plating marasa lantarki, kamar rage wakilai da na'urori masu daidaitawa, gabaɗaya sun fi na musamman da tsada.

Farashin kayan aiki:

Rukunin sakawa suna buƙatar ƙarin hadaddun kayan aiki masu tsada, gami da kayan wuta, masu gyarawa da anodes. Tsarukan platin jan ƙarfe maras amfani da wutar lantarki sun fi sauƙi kuma suna buƙatar ƴan abubuwa kaɗan.

Kudin kulawa:

Kayan aikin sakawa na iya buƙatar kulawa na lokaci-lokaci, daidaitawa, da maye gurbin anodes ko wasu abubuwan haɗin gwiwa. Tsarukan platin jan ƙarfe maras amfani da wutar lantarki gabaɗaya yana buƙatar ƙarancin kulawa akai-akai kuma suna da ƙarancin kulawa gabaɗaya.

Amfanin Plating Chemicals:

Tsarin plating yana cinye sinadarai na plating a mafi girma saboda amfani da wutar lantarki. Yawan amfani da sinadarai na tsarin plating na jan ƙarfe mara igiyar ruwa ya yi ƙasa da ƙasa saboda halayen lantarki yana faruwa ta hanyar halayen sinadarai.

Kudin sarrafa sharar gida:

Electroplating yana haifar da ƙarin sharar gida, gami da kashe platin wanka da kurkura ruwan da aka gurbata da ions karfe, waɗanda ke buƙatar magani da zubar da su. Wannan yana ƙara yawan farashin plating. Plating tagulla mara amfani da wutar lantarki yana haifar da ƙarancin sharar gida saboda baya dogara ga ci gaba da samar da ion ƙarfe a cikin wankan plating.

Matsaloli da ƙalubale na Electroplating da Zuba Sinadarai:

Electroplating yana buƙatar kulawa da hankali na sigogi daban-daban kamar yawa na yanzu, zafin jiki, pH, lokacin plating da motsawa. Samun damar ajiya iri ɗaya da halayen plating ɗin da ake so na iya zama ƙalubale, musamman a cikin hadaddun geometries ko ƙananan wuraren yanzu. Inganta abun da ke ciki na plating na wanka da sigogi na iya buƙatar gwaji mai yawa da ƙwarewa.

Plating na jan ƙarfe mara amfani da wutar lantarki kuma yana buƙatar sarrafa sigogi kamar rage tattarawar wakili, zafin jiki, pH da lokacin plating. Koyaya, sarrafa waɗannan sigogi gabaɗaya ba shi da mahimmanci a cikin plating marasa lantarki fiye da na lantarki. Samun abubuwan da ake so plating, kamar ƙimar ajiya, kauri, da mannewa, na iya buƙatar haɓakawa da saka idanu kan tsarin platin.

A cikin electroplating da lantarki plating jan karfe, mannewa zuwa daban-daban substrate kayan iya zama na kowa kalubale. Gabatarwar jiyya na ƙasa don cire gurɓatawa da haɓaka mannewa yana da mahimmanci ga matakai biyu.

Shirya matsala da warware matsala a cikin lantarki ko platin jan ƙarfe mara amfani da lantarki yana buƙatar ƙwarewa da ƙwarewa na musamman. Batutuwa kamar rashin daidaituwa, rashin daidaituwa, rashin daidaituwa, kumfa, ko mannewa mara kyau na iya faruwa yayin tafiyar matakai biyu, kuma gano tushen dalilin da ɗaukar matakin gyara na iya zama ƙalubale.

Iyakar aikace-aikacen kowace fasaha:

Ana amfani da Electroplating a masana'antu iri-iri da suka haɗa da na'urorin lantarki, motoci, sararin samaniya da kayan adon da ke buƙatar madaidaicin sarrafa kauri, ƙaƙƙarfan ƙaƙƙarfan ƙayyadaddun ƙayyadaddun abubuwa na zahiri. Ana amfani da shi sosai a cikin kayan ado na kayan ado, suturar ƙarfe, kariya ta lalata da masana'anta na kayan lantarki.

Ana amfani da plating maras amfani da wutar lantarki a masana'antar lantarki, musamman wajen kera allunan da'ira (PCBs). Ana amfani da shi don ƙirƙirar hanyoyin da za a iya sarrafawa, filaye masu iya siyarwa da ƙarewar saman akan PCBs. Hakanan ana amfani da platin jan ƙarfe maras amfani don haɓaka robobi, samar da haɗin haɗin tagulla a cikin fakitin semiconductor, da sauran aikace-aikacen da ke buƙatar yunifom da ajiyar tagulla.

4.Copper deposition dabaru don daban-daban PCB iri

PCB mai gefe guda:

A cikin PCB masu gefe guda, ana yin jibge-buge na jan karfe ta amfani da tsari mai ragi. Yawanci ana yin sa ne da wani abu mara amfani kamar FR-4 ko resin phenolic, wanda aka lulluɓe shi da bakin ƙarfe na jan ƙarfe a gefe ɗaya. Layin jan ƙarfe yana aiki azaman hanyar gudanarwa don kewayawa. Tsarin yana farawa tare da tsaftacewa da kuma shirye-shiryen shimfidar wuri don tabbatar da mannewa mai kyau. Na gaba shine aikace-aikacen siriri na kayan aikin hoto, wanda aka fallasa zuwa hasken UV ta hanyar hoto don ayyana tsarin kewayawa. Wuraren da aka fallasa na juriya sun zama masu narkewa kuma an wanke su daga baya, suna fallasa maƙallan jan ƙarfe. Wuraren jan karfe da aka fallasa ana yin su ta amfani da wani abu kamar ferric chloride ko ammonium persulfate. Ecchant ɗin yana zaɓin cire jan ƙarfe da aka fallasa, yana barin tsarin da'irar da ake so. Sauran juriya an cire su, barin alamun tagulla. Bayan tsarin etching, PCB na iya ɗaukar ƙarin matakan shirye-shiryen ƙasa kamar abin rufe fuska, bugu na allo, da aikace-aikacen yadudduka masu kariya don tabbatar da dorewa da kariya daga abubuwan muhalli.

PCB mai gefe biyu:

PCB mai gefe biyu yana da yadudduka na tagulla a ɓangarorin biyu na ma'auni. Tsarin ajiye jan karfe a bangarorin biyu ya ƙunshi ƙarin matakai idan aka kwatanta da PCBs masu gefe guda. Tsarin yana kama da PCB mai gefe guda, yana farawa tare da tsaftacewa da shirye-shiryen saman ƙasa. Sannan ana ajiye wani Layer na tagulla a ɓangarorin biyu na ma'aunin ta hanyar amfani da platin jan ƙarfe mara igiyar ruwa ko lantarki. Ana amfani da Electroplating yawanci don wannan matakin saboda yana ba da damar mafi kyawun iko akan kauri da ingancin layin jan karfe. Bayan an ajiye Layer na jan karfe, an lulluɓe bangarorin biyu tare da photoresist kuma ana siffanta tsarin kewaye ta hanyar fallasa da matakan haɓaka kama da na PCBs masu gefe guda. Sai a lissafta wuraren tagulla da aka fallasa don samar da alamun da'irar da ake buƙata. Bayan etching, an cire juriyar kuma PCB ta wuce ta ƙarin matakai na sarrafawa kamar aikace-aikacen abin rufe fuska da jiyya don kammala ƙirƙira na PCB mai gefe biyu.

Multilayer PCB:

Multilayer PCBs an yi su ne da yadudduka na tagulla da kayan rufewa da aka jera a saman juna. Jadawalin jan ƙarfe a cikin PCBs masu yawa ya ƙunshi matakai da yawa don ƙirƙirar hanyoyin gudanarwa tsakanin yadudduka. Tsarin yana farawa da ƙirƙira nau'ikan PCB guda ɗaya, kama da PCB masu gefe ɗaya ko biyu. An shirya kowane Layer kuma ana amfani da photoresist don ayyana tsarin kewayawa, sannan a saka tagulla ta hanyar lantarki ko plating tagulla mara amfani. Bayan ajiya, kowane Layer yana mai rufi da wani abu mai rufewa (yawanci prepreg na tushen epoxy ko resin) sannan a tattara su tare. An daidaita yadudduka ta amfani da hakowa daidai da hanyoyin rajista na inji don tabbatar da ingantacciyar haɗin kai tsakanin yadudduka. Da zarar yadudduka sun daidaita, ana ƙirƙira ta hanyar hakowa ta cikin yadudduka a takamaiman wuraren da ake buƙatar haɗin kai. Daga nan kuma ana lulluɓe ta da tagulla ta hanyar amfani da lantarki ko platin jan ƙarfe mara amfani da wutar lantarki don ƙirƙirar haɗin lantarki tsakanin yadudduka. Ana ci gaba da aiwatarwa ta hanyar maimaita matakan tarawa Layer, hakowa, da saka tagulla har sai an ƙirƙiri duk yadudduka da haɗin kai da ake buƙata. Mataki na ƙarshe ya haɗa da jiyya na ƙasa, aikace-aikacen abin rufe fuska da sauran hanyoyin gamawa don kammala masana'antar PCB mai yawan Layer.

Babban Haɗin Haɗin Maɗaukaki (HDI) PCB:

HDI PCB PCB ce mai nau'i-nau'i da yawa da aka ƙera don ɗaukar manyan kewayawa da ƙananan nau'i. Jadawalin jan ƙarfe a cikin HDI PCBs ya ƙunshi ingantattun dabaru don ba da damar ingantattun fasalulluka da ƙira mai tsauri. Tsarin yana farawa ta hanyar ƙirƙirar yadudduka-na bakin ciki da yawa, galibi ana kiran su ainihin abu. Waɗannan nau'ikan suna da foil na jan ƙarfe na bakin ciki a kowane gefe kuma an yi su daga kayan aikin guduro masu girma kamar BT (Bismaleimide Triazine) ko PTFE (Polytetrafluoroethylene). An tattara mahimman kayan aikin kuma an haɗa su tare don ƙirƙirar tsari mai yawa. Ana amfani da hakowar Laser don ƙirƙirar microvias, waɗanda ƙananan ramuka ne waɗanda ke haɗa yadudduka. Microvias yawanci suna cike da kayan aiki kamar jan ƙarfe ko epoxy mai ɗaukar nauyi. Bayan an kafa microvias, ƙarin yadudduka ana tarawa kuma an rufe su. Ana maimaita tsarin lamination da laser hakowa don ƙirƙirar yadudduka da yawa tare da haɗin haɗin microvia. A ƙarshe, ana ajiye jan ƙarfe a saman HDI PCB ta amfani da dabaru irin su electroplating ko plating tagulla mara amfani. Ganin kyawawan fasalulluka da babban kewayon HDI PCBs, ana sarrafa ajiya a hankali don cimma kauri da ingancin da ake buƙata na tagulla. Tsarin yana ƙarewa tare da ƙarin jiyya na saman ƙasa da matakan gamawa don kammala masana'antar HDI PCB, wanda zai iya haɗawa da aikace-aikacen abin rufe fuska, aikace-aikacen gamawa da gwaji.

Allon kewayawa mai sassauƙa:

PCBs masu sassauƙa, waɗanda kuma aka fi sani da flex circuits, an ƙera su don su kasance masu sassauƙa da iya daidaitawa da siffofi daban-daban ko lanƙwasa yayin aiki. Jadawalin jan ƙarfe a cikin PCBs masu sassauƙa ya ƙunshi takamaiman dabaru waɗanda suka dace da sassauci da buƙatun dorewa. PCBs masu sassauƙa na iya zama mai gefe ɗaya, mai gefe biyu, ko mai nau'i-nau'i da yawa, kuma fasahohin shigar da tagulla sun bambanta dangane da buƙatun ƙira. Gabaɗaya magana, PCBs masu sassauƙa suna amfani da foil ɗin tagulla mafi sira idan aka kwatanta da m PCBs don samun sassauci. Don PCBs masu sassauƙa mai gefe guda, tsarin yana kama da PCBs masu tsauri mai gefe guda, wato, ana ajiye bakin ƙarfe na jan ƙarfe akan madaidaicin madaidaicin ta amfani da platin jan ƙarfe mara igiyar lantarki, electroplating, ko haɗin duka biyun. Don PCBs masu sassauƙa mai gefe biyu ko Multi-Layer, tsarin ya haɗa da saka tagulla a ɓangarorin biyu na sassauƙan madaidaicin ta amfani da platin jan ƙarfe mara ƙarfi ko lantarki. Yin la'akari da ƙayyadaddun kayan aikin injiniya na kayan aiki masu sassauƙa, ana sarrafa ajiya a hankali don tabbatar da mannewa mai kyau da sassauci. Bayan shigar da jan ƙarfe, PCB mai sassauƙa yana tafiya ta ƙarin matakai kamar hakowa, ƙirar kewaye, da matakan jiyya na saman don ƙirƙirar da'ira da ake buƙata da kammala kera PCB mai sassauƙa.

5.Ci gaba da Sabuntawa a cikin Deposition Copper akan PCBs

Ci gaban Fasaha na Kwanan baya: A cikin shekaru da yawa, fasahar jigila tagulla akan PCBs ta ci gaba da haɓakawa da haɓakawa, yana haifar da haɓaka aiki da aminci. Wasu sabbin ci gaban fasaha a cikin ajiyar tagulla na PCB sun haɗa da:

Fasaha ta ci gaba:

Sabbin fasahohin plating, irin su ƙwanƙwasa bugun jini da jujjuyawar bugun jini, an ƙirƙira su don cimma mafi kyawu da ƙari iri-iri na jan ƙarfe. Waɗannan fasahohin na taimakawa wajen shawo kan ƙalubale kamar ƙaƙƙarfan ƙasa, girman hatsi da rarraba kauri don haɓaka aikin lantarki.

Karfe kai tsaye:

Masana'antar PCB ta al'ada ta ƙunshi matakai da yawa don ƙirƙirar hanyoyin gudanar da aiki, gami da ajiye layin iri kafin saka tagulla. Haɓaka matakan ƙarfe kai tsaye yana kawar da buƙatar nau'in nau'in iri daban-daban, ta haka yana sauƙaƙe tsarin masana'anta, rage farashin da haɓaka dogaro.

Fasahar Microvia:

Microvias ƙananan ramuka ne waɗanda ke haɗa yadudduka daban-daban a cikin PCB multilayer. Ci gaba a cikin fasahar microvia kamar hakowa Laser da etching plasma suna ba da damar ƙirƙirar ƙananan ƙananan microvias, ba da damar mafi girman da'irori da ingantaccen sigina. Tsarin farfajiya na farfajiya: Gama Gama Gama Gama Gama Gama Gama mafi mahimmanci yana da mahimmanci don kare clors daga shaka da rashin ƙarfi. Haɓakawa a cikin fasahar jiyya ta sama, kamar Immersion Azurfa (ImAg), Organic Solderability Preservative (OSP), da Electroless Nickel Immersion Gold (ENIG), suna ba da mafi kyawun lalata kariya, haɓaka solderability, da haɓaka amincin gabaɗaya.

Nanotechnology da Copper Deposition: Nanotechnology taka muhimmiyar rawa a ci gaban PCB jan karfe ajiya. Wasu aikace-aikacen nanotechnology a cikin ajiyar tagulla sun haɗa da:

Nanoparticle plating:

Za a iya shigar da nanoparticles na jan ƙarfe a cikin maganin plating don haɓaka tsarin ajiya. Wadannan nanoparticles suna taimakawa inganta mannewar jan karfe, girman hatsi da rarrabawa, don haka rage juriya da haɓaka aikin lantarki.

Kayayyakin Gudanar da Nanostructured:

Nanostructured kayan, kamar carbon nanotubes da graphene, za a iya hadedde a cikin PCB substrates ko zama conductive fillers a lokacin ajiya. Waɗannan kayan suna da haɓakar wutar lantarki mafi girma, ƙarfin injina da kaddarorin thermal, don haka haɓaka aikin PCB gabaɗaya.

Nanocoating:

Nanocoating za a iya amfani da PCB surface don inganta surface santsi, solderability da lalata kariya. Ana yin waɗannan sutura sau da yawa daga nanocomposites waɗanda ke ba da mafi kyawun kariya daga abubuwan muhalli da tsawaita rayuwar PCB.

Haɗin haɗin Nanoscale:Ana bincika haɗin haɗin Nanoscale, kamar nanowires da nanorods, don ba da damar da'irori masu yawa a cikin PCBs. Waɗannan sifofi suna sauƙaƙe haɗawa da ƙarin da'irori zuwa ƙaramin yanki, yana ba da damar haɓaka ƙananan na'urori masu ƙarfi na lantarki.

Kalubale da kwatance na gaba: Duk da gagarumin ci gaba, ƙalubale da dama da dama sun rage don ƙara haɓaka jibgewar tagulla akan PCBs. Wasu ƙalubalen ƙalubale da jagororin gaba sun haɗa da:

Cika Copper a Babban Tsarin Ratio Mai Girma:

Babban tsarin rabo mai girma kamar vias ko microvias suna gabatar da ƙalubale wajen samun yunifom da amintaccen cikawar tagulla. Ana buƙatar ƙarin bincike don haɓaka dabarun gyare-gyaren gyare-gyare ko madadin hanyoyin cikewa don shawo kan waɗannan ƙalubalen da kuma tabbatar da daidaitaccen ajiyar tagulla a cikin babban yanayin rabo.

Rage Nisa Na Tagulla:

Yayin da na'urorin lantarki suka zama ƙarami kuma suna daɗaɗaɗawa, buƙatar kunkuntar alamun tagulla na ci gaba da girma. Kalubalen shine a cimma daidaito da abin dogaro da jan ƙarfe a cikin waɗannan ƴan ƙunƙun alamun, tabbatar da daidaiton aikin lantarki da aminci.

Madadin kayan madugu:

Duk da yake jan ƙarfe shine abin da aka fi amfani da shi na madugu, madadin kayan kamar su azurfa, aluminium, da carbon nanotubes ana binciko su don ƙayyadaddun kaddarorinsu da fa'idodin aiki. Bincike na gaba na iya mayar da hankali kan haɓaka dabarun sakawa don waɗannan madadin kayan gudanarwa don shawo kan ƙalubale kamar mannewa, tsayayya, da dacewa tare da tsarin masana'antar PCB. MuhalliTsarin Sada Zumunta:

The PCB masana'antu ne kullum aiki zuwa muhalli m matakai. Abubuwan da ke faruwa na gaba na iya mayar da hankali kan rage ko kawar da amfani da sinadarai masu haɗari yayin ajiyar tagulla, inganta amfani da makamashi, da rage yawan sharar gida don rage tasirin muhalli na masana'antar PCB.

Advanced Simulation da Modeling:

Dabarun kwaikwaiyo da ƙirar ƙirar ƙira suna taimakawa haɓaka hanyoyin jigilar tagulla, tsinkaya halayyar sigogin ajiya, da haɓaka daidaito da ingancin masana'antar PCB. Ci gaban gaba na iya haɗawa da haɗa siminti na ci gaba da kayan aikin ƙira a cikin ƙira da ƙirar ƙira don ba da damar ingantacciyar sarrafawa da haɓakawa.

6.Quality Assurance da Control of Copper Deposition for PCB Substrates

Muhimmancin tabbatar da inganci: Tabbacin inganci yana da mahimmanci a cikin tsarin jibgewar tagulla saboda dalilai masu zuwa:

Amincewar samfur:

Jadawalin jan ƙarfe akan PCB shine tushen haɗin wutar lantarki. Tabbatar da ingancin ajiyar tagulla yana da mahimmanci ga abin dogaro da dorewa na na'urorin lantarki. Rashin ƙarancin jan ƙarfe na iya haifar da kurakuran haɗin gwiwa, rage sigina, da rage amincin PCB gabaɗaya.

Ayyukan lantarki:

Ingancin platin tagulla kai tsaye yana shafar aikin lantarki na PCB. Uniform jan karfe kauri da kuma rarraba, m surface gama, da kuma dace mannewa suna da muhimmanci ga cimma low juriya, m watsa sigina, da kadan sigina asarar.

Rage farashi:

Tabbacin ingancin yana taimakawa ganowa da hana matsaloli a farkon tsari, rage buƙatar sake yin aiki ko goge PCBs masu lahani. Wannan na iya adana farashi da haɓaka ingantaccen masana'anta gabaɗaya.

Gamsar da Abokin Ciniki:

Samar da samfurori masu inganci yana da mahimmanci ga gamsuwar abokin ciniki da gina kyakkyawan suna a cikin masana'antu. Abokan ciniki suna tsammanin samfuran abin dogaro kuma masu dorewa, kuma ingantaccen tabbacin yana tabbatar da adadin jan ƙarfe ya cika ko ya wuce waɗannan tsammanin.

Gwaje-gwaje da hanyoyin dubawa don ajiyar tagulla: Ana amfani da gwaje-gwaje iri-iri da hanyoyin dubawa don tabbatar da ingancin ajiyar tagulla akan PCBs. Wasu hanyoyin gama gari sun haɗa da:

Duban gani:

Duban gani hanya ce ta asali kuma muhimmiyar hanya ta gano lahani na zahiri kamar su karce, haƙora ko rashin ƙarfi. Ana iya yin wannan binciken da hannu ko tare da taimakon tsarin dubawar gani mai sarrafa kansa (AOI).

Microscope:

Microscope ta amfani da dabaru irin su sikanin microscope na lantarki (SEM) na iya ba da cikakken bincike game da saka jan karfe. Yana iya a hankali duba ƙarewar farfajiya, mannewa da daidaituwar Layer na jan karfe.

Binciken X-ray:

Ana amfani da dabarun bincike na X-ray, irin su X-ray fluorescence (XRF) da X-ray diffraction (XRD), don auna abun da ke ciki, kauri da rarraba ajiyar tagulla. Waɗannan fasahohin na iya gano ƙazanta, abun da ke ciki na asali, da gano duk wani rashin daidaituwa a cikin ajiyar tagulla.

Gwajin Lantarki:

Yi hanyoyin gwajin lantarki, gami da ma'aunin juriya da gwajin ci gaba, don kimanta aikin wutar lantarki na ajiyar tagulla. Waɗannan gwaje-gwajen suna taimakawa tabbatar da cewa layin jan ƙarfe yana da aikin da ake buƙata kuma babu buɗewa ko gajerun wando a cikin PCB.

Gwajin Ƙarfin Kwasfa:

Gwajin ƙarfin kwasfa yana auna ƙarfin haɗin kai tsakanin layin jan karfe da maƙallan PCB. Yana ƙayyade ko ajiyar tagulla yana da isassun ƙarfin haɗin gwiwa don jure aiki na yau da kullun da tsarin masana'antar PCB.

Matsayin masana'antu da ka'idoji: Masana'antar PCB suna bin ka'idodin masana'antu daban-daban da ka'idoji don tabbatar da ingancin ajiyar tagulla. Wasu muhimman ka'idoji da ka'idoji sun haɗa da:

IPC-4552:

Wannan ma'auni yana ƙayyadaddun buƙatun don nickel / immersion zinariya (ENIG) maras amfani da kayan aikin jiyya da aka saba amfani da su akan PCBs. Yana bayyana mafi ƙarancin kauri na gwal, kauri na nickel da ingancin saman don ingantaccen jiyya na saman ENIG.

IPC-A-600:

Ma'auni na IPC-A-600 yana ba da jagororin karɓuwa na PCB, gami da ka'idodin rarrabuwar tagulla, lahani da sauran ƙa'idodi masu inganci. Yana aiki azaman tunani don dubawa na gani da ma'auni na yarda da ajiyar tagulla akan PCBs. Umarnin RoHS:

Umarnin Ƙuntata Abubuwan Haɗaɗɗen Abubuwa (RoHS) yana ƙuntata amfani da wasu abubuwa masu haɗari a cikin samfuran lantarki, gami da gubar, mercury da cadmium. Bi umarnin RoHS yana tabbatar da cewa ajiyar tagulla akan PCBs ba su da abubuwa masu cutarwa, yana sa su zama mafi aminci kuma mafi aminci ga muhalli.

ISO 9001:

ISO 9001 shine ma'auni na duniya don tsarin gudanarwa mai inganci. Ƙirƙirar da aiwatar da tsarin gudanarwa mai inganci na tushen ISO 9001 yana tabbatar da cewa ana aiwatar da matakai da sarrafawa masu dacewa don sadar da samfuran da suka dace da bukatun abokin ciniki, gami da ingancin ajiyar tagulla akan PCBs.

Rage matsalolin gama gari da lahani: Wasu matsalolin gama gari da lahani waɗanda zasu iya faruwa yayin sanya jan ƙarfe sun haɗa da:

Rashin isasshen mannewa:

Rashin mannewa Layer na jan karfe zuwa ga abin da zai iya haifar da delamination ko kwasfa. Tsabtace ƙasa mai kyau, jujjuyawar injina, da haɓaka jiyya na adhesion na iya taimakawa wajen rage wannan matsalar.

Kauri mara daidaituwa:

Rashin daidaito kauri na jan karfe na iya haifar da rashin daidaituwar aiki da kuma hana watsa sigina. Haɓaka sigogin plating, ta amfani da bugun bugun jini ko juyawa bugun bugun jini da kuma tabbatar da tashin hankali na iya taimakawa wajen cimma kauri iri ɗaya.

Voids da Pinholes:

Voids da ramuka a cikin layin jan ƙarfe na iya lalata haɗin lantarki kuma yana ƙara haɗarin lalata. Gudanar da daidaitattun sigogin plating da amfani da abubuwan da suka dace na iya rage faruwar ɓarna da ramuka.

Taushin saman:

Wuce kitse na saman yana iya yin tasiri mara kyau na aikin PCB, yana shafar solderability da amincin lantarki. Gudanar da daidaitaccen ma'aunin ma'auni na jan ƙarfe, gyaran fuska da kuma hanyoyin da za a bi da su na taimakawa wajen cimma kyakkyawan yanayin.

Don rage waɗannan al'amurra da rashi, dole ne a aiwatar da matakan da suka dace, dole ne a gudanar da bincike da gwaje-gwaje na yau da kullum, kuma dole ne a bi ka'idodin masana'antu da ka'idoji. Wannan yana tabbatar da daidaito, abin dogaro da ƙima mai inganci akan PCB. Bugu da ƙari, gyare-gyaren tsari mai gudana, horar da ma'aikata, da hanyoyin amsawa suna taimakawa wajen gano wuraren da za a inganta da kuma magance matsalolin da za a iya fuskanta kafin su zama masu tsanani.

Jadawalin jan ƙarfe akan ma'aunin PCB muhimmin mataki ne a cikin tsarin masana'antar PCB. Jadawalin jan ƙarfe mara amfani da lantarki da lantarki sune manyan hanyoyin da ake amfani da su, kowanne yana da fa'idarsa da gazawarsa. Ci gaban fasaha na ci gaba da fitar da sabbin abubuwa a cikin ajiyar tagulla, don haka inganta aikin PCB da aminci.Tabbatar da inganci da sarrafawa suna taka muhimmiyar rawa wajen tabbatar da samar da PCB masu inganci. Kamar yadda buƙatun ƙarami, sauri, kuma mafi aminci na na'urorin lantarki ke ci gaba da ƙaruwa, haka buƙatar daidaito da inganci a fasahar saka tagulla akan abubuwan PCB. Lura: Kalmomin labarin kusan kalmomi 3,500 ne, amma a lura cewa ainihin ƙidayar kalmar na iya bambanta kaɗan yayin aikin gyarawa da gyarawa.

Lokacin aikawa: Satumba-13-2023

Baya