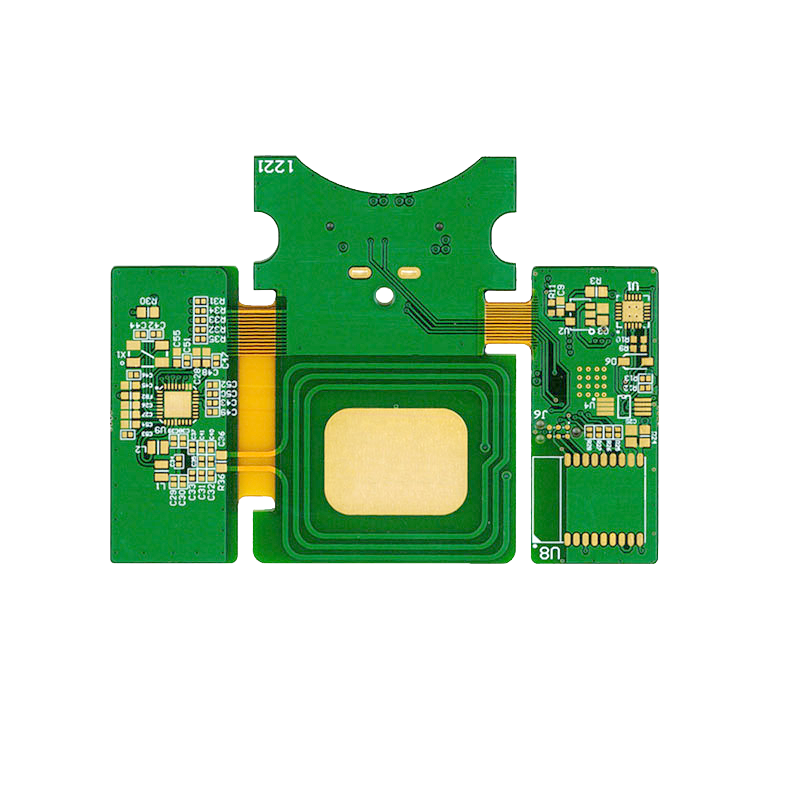

A cikin gasa ta masana'antar lantarki ta yau, ana ƙara buƙatar sabbin allunan da'ira (PCBs). Kamar yadda masana'antu ke girma, haka kuma buƙatar PCBs waɗanda zasu iya jure yanayin muhalli daban-daban da kuma biyan buƙatun na'urorin lantarki masu rikitarwa. Wannan shine inda manufar flex rigid-flex PCB ta shigo cikin wasa.

Kwamfuta masu tsattsauran ra'ayi suna ba da haɗin kai na musamman na kayan aiki masu mahimmanci da sassauƙa, suna sa su dace don aikace-aikacen da ke buƙatar ƙarfin hali da sassauci. Ana samun waɗannan allunan a cikin kayan aikin likita, tsarin sararin samaniya, da sauran aikace-aikacen ingantaccen abin dogaro.

Ikon impedance wani mahimmin al'amari ne wanda ke tasiri sosai ga aikin allunan sassauƙa. Impedance shine juriya da kewayawa ke bayarwa ga kwararar alternating current (AC). Kulawar da ya dace yana da mahimmanci yayin da yake tabbatar da ingantaccen watsa siginar kuma yana rage asarar wutar lantarki.

A cikin wannan shafin yanar gizon, Capel zai bincika abubuwa biyar waɗanda zasu iya tasiri sosai ga ikon sarrafawa na katako mai sassauƙa. Fahimtar waɗannan abubuwan yana da mahimmanci ga masu ƙira da masana'antun PCB don isar da samfuran inganci waɗanda suka dace da buƙatun duniyar da fasahar kere-kere ta yau.

1. Daban-daban substrates za su shafi darajar impedance:

Don Flex Rigid-Flex PCB, bambance-bambance a cikin kayan tushe yana da tasiri akan ƙimar impedance. A cikin allunan masu sassauƙa, mai sassauƙa mai sassauƙa da ƙaƙƙarfan ƙaƙƙarfan ƙaƙƙarfan ƙaƙƙarfan ƙayyadaddun ƙayyadaddun kayan aiki na yau da kullun suna da nau'ikan daidaitawar dielectric daban-daban da haɓakawa, wanda zai haifar da matsalolin rashin daidaituwa na impedance a mahaɗin tsakanin abubuwan biyu.

Musamman, masu sassauƙan sassauƙa suna da madaidaicin dielectric akai-akai da ƙananan ƙarancin wutar lantarki, yayin da maɗaukaki masu ƙarfi suna da ƙananan ƙarancin dielectric akai-akai kuma mafi girman halayen lantarki. Lokacin da siginar ta yaɗu a cikin ma'aunin da'ira mai ƙarfi, za a sami tunani da watsawa a mahaɗar madaidaicin pcb substrate. Wadannan tunani da al'amuran watsawa suna haifar da rashin daidaituwa na siginar don canzawa, wato, rashin daidaituwa na impedance.

Don mafi kyawun sarrafa impedance na pcb mai ƙarfi, ana iya ɗaukar waɗannan hanyoyin:

Zaɓin Substrate:zaɓi hade da m flex kewaye substrates sabõda haka, dielectric akai-akai da kuma conductivity sun kasance kusa da yadda zai yiwu don rage matsalar impedance mismatch;

Maganin mu'amala:jiyya na musamman don mu'amala tsakanin pcb m flex substrates, kamar yin amfani da na'urar dubawa ta musamman ko fim mai lanƙwasa, don haɓaka haɓakar impedance zuwa wani takamaiman matakin;

Ikon latsawa:A cikin masana'antu tsari na m m pcb, sigogi kamar zafin jiki, matsa lamba da kuma lokaci ana tsananin sarrafawa don tabbatar da kyau bonding m lankwasa kewaye hukumar substrates da rage impedance canje-canje;

Kwaikwayo da gyara kuskure:Ta hanyar kwaikwaya da bincike na siginar yaduwa a cikin pcb m m, gano matsalar rashin daidaituwa na impedance, da yin daidaitattun gyare-gyare da ingantawa.

2. Layin nisa tazara wani muhimmin al'amari ne da ke shafar sarrafa impedance:

A cikin jirgi mai ƙarfi-flex, tazarar nisa na layin yana ɗaya daga cikin mahimman abubuwan da ke shafar sarrafa impedance. Faɗin layi (watau nisa na waya) da tazarar layi (watau nisa tsakanin wayoyi masu kusa) suna ƙayyade lissafi na hanyar yanzu, wanda hakan yana rinjayar halayen watsawa da ƙimar siginar.

Mai biyowa shine tasirin tazarar faɗin layin akan ikon sarrafa magudanar ruwa mai ƙarfi:

Muhimmin Tasiri:Tazarar layi yana da mahimmanci don sarrafa ainihin abin ƙyama (watau, sifa ta layukan microstrip, igiyoyin coaxial, da sauransu). Dangane da ka'idar layin watsawa, abubuwa kamar faɗin layi, tazarar layi, da kauri tare da ƙayyadaddun ƙayyadaddun halayen layin watsawa. Lokacin da nisa tazara ya canza, zai haifar da canji a cikin siffa mai ma'ana, ta haka yana shafar tasirin siginar.

Daidaita impedance:Sau da yawa ana buƙatar matching impedance a cikin tsayayyen allo don tabbatar da mafi kyawun watsa sigina a cikin kewaye. Daidaitawar impedance yawanci yana buƙatar daidaita tazarar faɗin layin don cimmawa. Alal misali, a cikin layin microstrip, halayen halayen layin watsawa za a iya daidaita su da maƙasudin da tsarin ke buƙata ta hanyar daidaita nisa na masu gudanarwa da kuma tazara tsakanin masu gudanarwa na kusa.

Magana da Asara:Tazarar layi kuma yana da tasiri mai mahimmanci akan sarrafa tatsuniyoyi da asara. Lokacin da tazarar faɗin layi ya yi ƙanƙanta, ana haɓaka tasirin haɗin wutar lantarki tsakanin wayoyi da ke kusa, wanda zai iya haifar da haɓakar magana. Bugu da ƙari, ƙananan faɗin waya da tazarar waya mafi girma suna haifar da ƙarin rarrabawar yanzu, ƙara juriya da asara.

3. Kauri daga cikin kayan kuma shine muhimmin mahimmancin da ke shafar kula da impedance na katako mai sassauƙa:

Bambance-bambance a cikin kauri na abu kai tsaye yana shafar siffar siffa ta layin watsawa.

Mai zuwa shine tasirin kauri na abu akan sarrafa impedance na alluna masu sassauƙa:

Siffar layin watsawa impedance:Siffar rashin ƙarfi na layin watsawa yana nufin alaƙar daidaituwa tsakanin na yanzu da ƙarfin lantarki akan layin watsawa a takamaiman mitar. A cikin jirgi mai ƙarfi-flex, kauri daga cikin kayan zai shafi ƙimar sifa mai mahimmanci na layin watsawa. Gabaɗaya magana, lokacin da kauri abu ya zama sirara, haɓakar halayen halayen za su ƙaru; kuma lokacin da kauri abu ya yi kauri, halayen halayen halayen zai ragu. Sabili da haka, lokacin zayyana katako mai tsauri, ya zama dole don zaɓar kauri mai dacewa don cimma ƙimar halayen da ake buƙata bisa ga buƙatun tsarin da halayen watsa sigina.

Rabon Layi-zuwa-Sarari:Bambance-bambance a cikin kauri na abu kuma zai shafi rabon layi-zuwa-tazara. Dangane da ka'idar layin watsawa, siffa mai siffa tana daidai da rabon faɗin layi zuwa sarari. Lokacin da kauri kayan ya canza, don kiyaye kwanciyar hankali na halayen halayen halayen, ya zama dole don daidaita ma'auni na fadin layi da tazarar layi daidai. Misali, lokacin da aka rage kauri na kayan, don ci gaba da ci gaba da haɓaka halayen halayen, ana buƙatar rage faɗin layin daidai da haka, kuma yakamata a rage tazarar layin daidai don kiyaye faɗin layin zuwa yanayin sararin samaniya ba canzawa.

4. Haƙuri na jan ƙarfe na lantarki kuma wani abu ne da ke shafar iko mai ƙarfi na katako mai sassauƙa:

Electroplated jan karfe ne da aka saba amfani da conductive Layer a cikin m-launi alluna, da kuma canje-canje a cikin kauri da kuma haƙuri zai shafi kai tsaye halin impedance na hukumar.

Mai zuwa shine tasirin jurewar jan ƙarfe na lantarki akan ikon sarrafa madaidaitan alluna masu sassauƙa:

Hakuri kaurin jan ƙarfe na lantarki:Kaurin jan ƙarfe na lantarki yana ɗaya daga cikin mahimman abubuwan da ke tasiri ga ƙwaƙƙwaran allo mai ƙarfi. Idan kauri haƙuri na electroplated jan karfe ya yi girma da yawa, kauri daga cikin conductive Layer a kan farantin zai canza, game da shi rinjayar da halayyar impedance na farantin. Don haka, lokacin kera allunan gyare-gyare masu ƙarfi, wajibi ne don sarrafa kauri mai kauri na jan ƙarfe na lantarki don tabbatar da kwanciyar hankali na halayen halayen.

Uniformity na electroplating jan karfe:Baya ga juriyar kauri, daidaiton jan ƙarfe na lantarki kuma yana shafar ikon sarrafa alluna masu ƙarfi. Idan akwai rashin daidaituwa na rarraba Layer na jan ƙarfe a kan allo, wanda ya haifar da kauri daban-daban na jan ƙarfe na lantarki a wurare daban-daban na allon, yanayin halayen ma zai canza. Sabili da haka, wajibi ne don tabbatar da daidaituwa na jan ƙarfe na lantarki don tabbatar da daidaiton halayen halayen halayen lokacin da aka kera katako mai laushi da m.

5. Haƙurin etching shima muhimmin abu ne da ke shafar ikon sarrafa alluna masu ƙarfi:

Haƙurin etching yana nufin karkatar da kauri daga cikin farantin da za a iya sarrafawa lokacin da ake aiwatar da etching a cikin aiwatar da kera katako mai sassauƙa.

Abubuwan da ke biyowa sune tasirin etching tolerances akan sarrafa impedance na alluna masu sassauƙa:

Matching da matching na m-flex board: A cikin tsarin masana'antu na katako mai sassauƙa, yawanci ana amfani da etching don sarrafa ƙimar ƙima. Ta hanyar etching, za a iya daidaita nisa na Layer conductive don cimma ƙimar impedance da ƙira ke buƙata. Koyaya, yayin aiwatar da etching, tunda saurin etching na maganin etching akan farantin na iya samun ɗan haƙuri, ana iya samun rarrabuwa a cikin nisa na layin gudanarwa bayan etching, wanda ke shafar daidaitaccen iko na halayen halayen.

Daidaituwa a cikin siffa ta impedance:Etching tolerances kuma zai iya haifar da bambance-bambance a cikin kauri na conductive Layer a yankuna daban-daban, haifar da rashin daidaito halayyar impedance. Rashin daidaituwar halayen halayen halayen na iya rinjayar aikin watsa siginar, wanda ke da mahimmanci a cikin sadarwa mai sauri ko aikace-aikace mai girma.

Ikon impedance wani muhimmin al'amari ne na ƙirar Flex Rigid-Flex PCB da ƙirƙira.Samun daidaitattun ƙima mai ƙima yana da mahimmanci ga amintaccen watsa siginar da aikin gabaɗayan na'urorin lantarki.Don haka ta hanyar ba da hankali sosai ga zaɓin zaɓi, nau'ikan nau'ikan lissafi, kauri mai sarrafa ƙarfi, juriya plating na jan ƙarfe, da ƙarancin haƙuri, PCB masu zanen kaya da masana'antun na iya samun nasarar isar da ingantattun alluna masu ƙarfi, masu inganci waɗanda suka dace da ƙaƙƙarfan buƙatun masana'antu. shekaru 15 na raba kwarewar masana'antu, Ina fata Capel zai iya kawo muku taimako mai amfani. Don ƙarin tambayoyin hukumar da'ira, da fatan za a tuntuɓe mu kai tsaye, ƙwararrun ƙwararrun hukumar da'ira ta Capel za su amsa muku akan layi.

Lokacin aikawa: Agusta-22-2023

Baya