Gano yadda fasahar masana'anta ta FPC-Flex PCB ta Capel ta gamu da kalubalen samarwa2-Layer Flex PCBs don sabon abin hawa makamashiallon kariyar baturi. Nutse cikin ƙwarewar fasaha da tasirin masana'antu na wannan binciken shari'ar mai nasara.

Gabatarwa

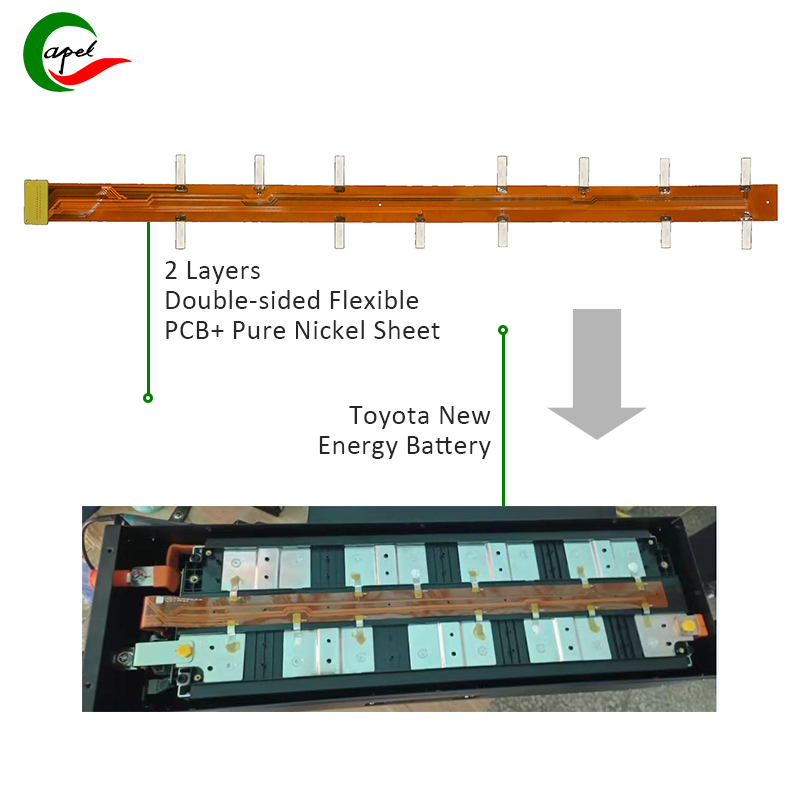

Sabbin motocin makamashi irinsu motocin lantarki da na'urorin haɗaɗɗiya sune kan gaba a harkar sufurin da ba ta dace da muhalli ba. Tare da ci gaban fasaha, sabbin motocin makamashi suna da ƙarin buƙatu don aiki mai girma, abin dogaro, da ingantaccen kayan lantarki. PCBs masu sassauƙa (da'irori masu sassauƙa) suna taka muhimmiyar rawa a waɗannan motocin, musamman a aikace-aikace kamar allunan da'irar kariyar baturi. A cikin wannan labarin, za mu yi zurfin duban yadda Capel ta tabbatar da fasahar aiwatar da FPC da kuma sababbin hanyoyin warware matsalolin masana'antu na musamman da abokan ciniki ke fuskanta a cikin mota.sabon makamashi abin hawa 2-Layer m PCB masana'anta.

Kalubalen abokin ciniki

Abokin ciniki, babban masana'anta a cikin sabbin masana'antar abin hawa makamashi, ya fuskanci ƙalubale mai tsanani lokacin samar da PCBs masu sassauƙa na Layer 2 don allon da'irar kariyar baturi. Takamaiman buƙatun don PCB mai sassauƙa sun haɗa da:

Kayayyaki: PCBs masu sassauƙa suna buƙatar gina su ta amfani da polyimide (PI) azaman maƙasudin maƙallan ƙarfe da jan ƙarfe da manne azaman layin haɗin gwiwa.

Faɗin layi da tazarar layi: Faɗin layi da tazarar layi suna buƙatar zama daidai zuwa 0.2mm/0.25mm don tabbatar da mutunci da aikin kewayawa.

Kauri farantin: An kayyade kauri na farantin azaman 0.25mm +/- 0.03mm, yana buƙatar tsananin yarda da juriya mai girma.

Mafi ƙarancin Ramin: PCB yana buƙatar ƙaramin rami na 0.1 mm don ɗaukar abubuwan da suka dace.

Jiyya na Surface: Electroless Nickel Immersion Gold (ENIG) jiyya a saman an wajabta shi don kyakkyawan halayensa da juriya na lalata.

Haƙuri: Abokan ciniki suna buƙatar tsauraran haƙuri na ± 0.1mm don cimma madaidaicin madaidaicin girman allo.

Maganin Capel da damar fasaha

Ƙwararrun ƙwararrun ƙwararrun ƙwararrun injiniyoyin FPC na Capel suna yin nazarin buƙatun abokin ciniki a hankali tare da ƙirƙira sabbin hanyoyin magance su don saduwa da wuce bukatun aikin. Anan ga yadda ƙwarewar fasahar Capel da ƙirƙira ke nuna nasarar sa wajen saduwa da ƙalubale na abokin ciniki:

Zaɓin Babban Kayayyaki da Sayayya: Zurfin ilimin Capel game da kaddarorin da halayen aikin polyimide, jan ƙarfe da kayan mannewa yana ba da damar zaɓi da sayayya. An zaɓi kayan inganci don tabbatar da aminci, sassauci da kwanciyar hankali na PCB masu sassauƙa, waɗanda ke da mahimmanci ga sabbin kayan aikin makamashi na kera.

Matsakaicin Tsarukan Masana'antu: Ci-gaba na masana'antu na Capel da gwaninta a cikin samfura da tsarin samarwa na FPC suna ba da damar aiwatar da daidaitattun faɗuwar layin da aka ƙayyade, tazarar layi, kaurin allo da mafi ƙarancin ramuka. Ana amfani da kayan aiki na zamani da tsauraran matakan kulawa don cimma daidaiton girman girman da ake buƙata da daidaito ga kowane PCB mai sassauƙa.

Mafi Girma Jiyya: Ana yin aikace-aikacen jiyya na saman nickel Immersion Gold (ENIG) tare da mafi girman daidaici kuma cikin bin ka'idodin masana'antu. Tsarin jiyya na saman Capel yana ba da ƙarfin aiki, solderability da dorewa da ake buƙata don saduwa da ƙaƙƙarfan buƙatun na'urorin lantarki na zamani.

Gudanar da Haƙuri da Tabbacin Inganci: Ƙullawar Capel na kiyaye juriya na ±0.1mm ana nunawa ta hanyar ƙa'idodin tabbatar da inganci. Kowane mataki na tsarin masana'antu ana yin bitarsa sosai don tabbatar da cewa PCB mai sassauƙa mai sassauƙa 2 da aka gama yana da ingantacciyar daidaito da aminci, saduwa da ƙaƙƙarfan ƙa'idodin sabbin masana'antar abin hawa makamashi.

Binciken Harka: Nasarar Abokin ciniki da Tasirin Masana'antu

Nasarar haɗin gwiwar Capel tare da abokan ciniki ya samar da PCB masu sassauƙa masu inganci 2 masu inganci waɗanda suka zarce tsammanin masana'antu. Ƙarfin aiki da daidaito na ƙera PCBs masu sassauƙa sun ba da babbar gudummawa ga sabbin kwamitocin kariyar baturi na abokan ciniki, haɓaka aminci da ingancin tsarin lantarki na abin hawa.

Ƙarfin fasaha da ƙirƙira da ke tattare a cikin balagaggen fasahar aiwatar da tsarin FPC na Capel suna da mahimmanci wajen fitar da wannan aikin zuwa kyakkyawan sakamako. Ƙarfin Capel na ci gaba da sadar da mafita na PCB masu sassauƙa na al'ada a cikin juzu'i da takamaiman buƙatun kayan aiki yana nuna ƙarfin Capel a wannan yanki. Tasirin wannan haɗin gwiwar ya wuce bayan nasarar abokin ciniki kai tsaye kuma yana nuna rawar da masana'antun FPC na ci gaba ke takawa wajen haɓaka ci gaban sabbin masana'antar motocin makamashi.

Yunkurin da Capel ya yi don ci gaba da ingantawa da ƙirƙira a cikin samfura da masana'antu na FPC ya tabbatar da cewa yana taimakawa wajen biyan buƙatun sabbin hanyoyin samar da makamashi. Wannan yanayin binciken ya nuna sadaukarwar Capel don samar da abin dogara, babban aiki da kuma hanyoyin da aka keɓance don ɗaga mashaya don samar da PCB mai sassauƙa a cikin kasuwar sabbin motocin makamashi mai saurin girma.

Sabbin Tsarin Kera Motocin PCB Makamashi

A karshe

A cikin yanayin yanayin sabbin fasahohin makamashi na kera motoci, ba za a iya yin la'akari da rawar FPC-Flex PCB samfuri da masana'anta ba. Nasarar binciken shari'ar Capel yana nuna ƙwarewar fasaha da ƙirƙira waɗanda ke tallafawa fasahar aiwatar da FPC. Ta hanyar warware takamaiman ƙalubalen samar da PCBs masu sassauƙa na Layer 2 don sabbin allunan kariyar baturi na makamashi, Capel ba wai kawai yana nuna iyawar sa ba har ma yana ba da gudummawa ga ci gaban na'urorin lantarki.

Yayin da masana'antu ke ci gaba da haɓakawa, haɗin gwiwar da ke tsakanin Capel da abokan ciniki yana nuna yiwuwar ƙaddamar da matakan FPC don fitar da sababbin abubuwa, inganci da aminci a cikin sababbin motocin makamashi. Binciken binciken shari'a yana nuna mahimmancin mahimmancin ƙwarewar fasaha, ƙirar ƙira da ƙima da sadaukar da kai ga inganci a cikin yanayin yanayin lantarki mai canzawa koyaushe. Tare da falsafancin abokin ciniki-centric da kuma neman kyakkyawan aiki, Capel ya ci gaba da saita sabbin ka'idoji don masana'antar FPC-Flex PCB a cikin sabon masana'antar abin hawa makamashi.

Wannan labarin yana ba da haske mai mahimmanci game da haɗin kai tsakanin fasaha na FPC-Flex PCB da sabon makamashi na gaba na mota, sanya Capel a matsayin jagora a samar da sababbin hanyoyin magance matsalolin sufuri na gaba na gaba.

Lokacin aikawa: Fabrairu-27-2024

Baya