Gabatarwa:

A cikin wannan zamani na fasaha mai saurin tafiya, buƙatun ƙirƙira cikin sauri ya sami gagarumin ci gaba, musamman a fannin ci gaban da'ar da'ira (PCB). Amma ta yaya injiniyoyi ke tabbatar da cewa saurin baya shafar siginar PCB?A cikin wannan gidan yanar gizon, za mu bincika dabaru da mafi kyawun ayyuka don taimaka muku ƙware fasahar ƙirar PCB mai sauri yayin la'akari da la'akari da amincin sigina a hankali.

Fahimtar mahimmancin amincin sigina a ƙirar PCB:

Mutuncin sigina yana nufin iyawar sigina don yadawa ta PCB ba tare da an karkata ba, ƙasƙantar da kai, ko ɓacewa yayin watsawa. Mutuncin sigina mara kyau na iya haifar da matsaloli iri-iri kamar kurakuran bayanai, ɓarnawar aiki, da ƙara saurin tsangwama. Lokacin yin samfur na PCBs, yana da mahimmanci a ba da fifikon amincin sigina don tabbatar da aiki da amincin samfurin ƙarshe.

1. Bi jagororin ƙira na sigina:

Don tabbatar da ingantacciyar siginar sigina, dole ne a bi takamaiman ƙa'idodin ƙira yayin lokacin samfur. Waɗannan jagororin sun haɗa da:

A. Sanya abubuwan da suka dace: Sanya abubuwan da suka dace akan PCB yana taimakawa rage tsawon alamun sigina, ta haka yana rage haɗarin lalata sigina.Haɗa abubuwan da ke da alaƙa tare da bin shawarwarin jeri na masana'anta matakai ne masu mahimmanci don haɓaka amincin sigina.

b. Daidaita tsayin sawu: Don sigina masu sauri, kiyaye tsayin sawu yana da mahimmanci don hana karkacewar lokaci da karkatar da sigina.Tabbatar cewa alamun da ke ɗauke da sigina iri ɗaya tsawonsu ɗaya ne don rage yuwuwar rashin daidaituwar lokaci.

C. Ƙwararren Ƙwararren Ƙwararren Ƙwararren Ƙwararren Ƙwararren Ƙwararren Ƙwararren Ƙwararren Ƙwararren Ƙwararren Ƙwararren Ƙwararren Ƙwararren Ƙwararren Ƙwararren Ƙwararren Ƙwararren Ƙwararren Ƙwararren Ƙwararren Ƙwararren Ƙwararren Ƙwararren Ƙwararren Ƙwararren Ƙwararren Ƙwararren Ƙwararren Ƙwararren Ƙwaƙwalwa na Ƙaƙwalwa na Ƙaƙwalwa na Ƙaƙwalwa na Ƙaƙwalwa na Ƙaƙwalwa ) na Ƙaddamarwa ya yi na inganta siginar siginar ta hanyar rage tunani.Dabarun sarrafa impedance, kamar sarrafa tashe-tashen hankula, suna da mahimmanci a aikace-aikacen mitoci masu yawa.

2. Yi amfani da manyan kayan aikin ƙirar PCB:

Yin amfani da software mai ƙira na PCB sanye take da iyawar nazarin ingancin sigina na iya sauƙaƙa aikin samfuri sosai. Waɗannan kayan aikin suna ba injiniyoyi damar kwaikwaya da kuma nazarin halayen ƙirar PCB kafin masana'anta don gano yuwuwar amincin siginar da wuri.

A. Kwaikwayo da Model: Yin wasan kwaikwayo yana ba da cikakkiyar ƙima game da halayen sigina, yana ba da haske game da abubuwan da suka shafi amincin sigina.Ta hanyar kwaikwayon al'amura daban-daban, masu zanen kaya na iya ganowa da gyara batutuwan da suka shafi tunani, crosstalk, da tsangwama na lantarki (EMI).

b. Duba Dokokin Zane (DRC): Aiwatar da DRC a cikin software na ƙira na PCB yana tabbatar da cewa ƙirar ta bi ƙayyadaddun ƙa'idodin amincin sigina.Yana taimakawa ganowa da warware kurakuran ƙira masu yuwuwa a cikin lokaci.

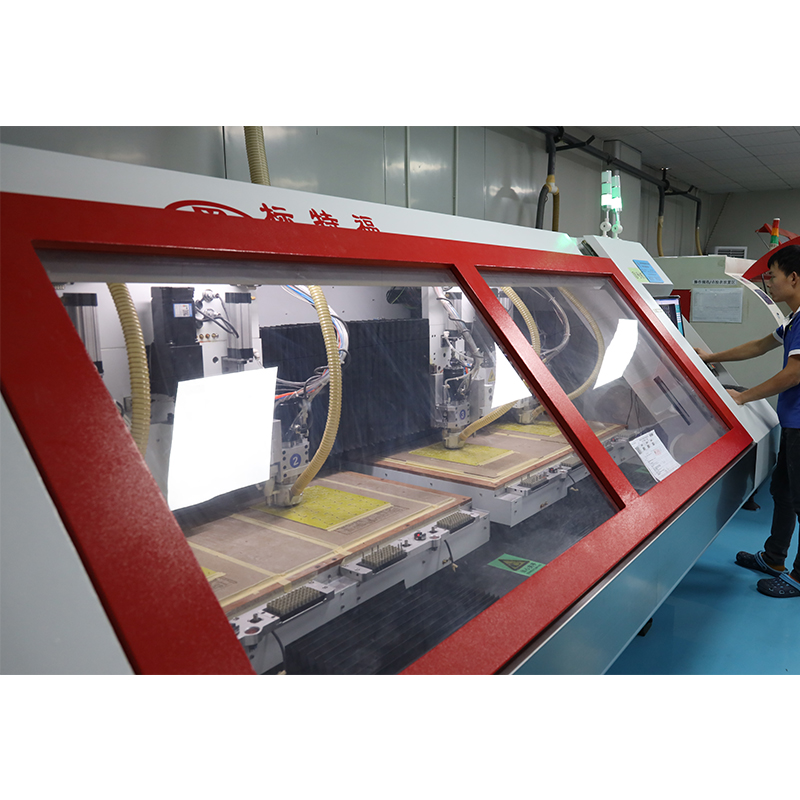

3. Haɗin kai tare da masana'antun PCB:

Yin aiki tare da gogaggen masana'anta na PCB tun daga farko na iya sauƙaƙa tsarin samfuri sosai. Masu sana'a na iya ba da haske mai mahimmanci game da al'amuran amincin sigina kuma suna ba da shawarar gyare-gyare don inganta ƙira.

A. Zaɓin Abu: Yin aiki tare da masana'anta zai ba ku damar zaɓar kayan da suka dace don ƙirar PCB ɗinku.Kayayyakin da ke da ƙarancin asarar tangin dielectric da madaurin dielectric mai sarrafawa na iya inganta amincin sigina.

b. Zane don Ƙirƙira (DFM): Haɗin masana'antun yayin lokacin ƙira yana tabbatar da cewa an inganta ƙirar don masana'anta kuma yana rage yuwuwar amincin siginar da ke haifar da ƙarancin ƙira.

4. Gwaji da ingantawa akai-akai:

Da zarar samfurin ya cika, dole ne a yi cikakken gwaji don tabbatar da ingancin siginar. Tsarin maimaitawa na gwaji, gano al'amura, da aiwatar da ingantawa yana da mahimmanci don cimma kyakkyawan ingancin sigina.

A ƙarshe:

Samfurin PCB mai sauri tare da amincin siginar a hankali na iya zama ƙalubale, amma ta hanyar amfani da dabarun ƙira masu dacewa, haɓaka kayan aikin ƙirar PCB na ci gaba, haɗin gwiwa tare da masana'antun, da gudanar da gwaje-gwajen juzu'i, injiniyoyi na iya haɓaka amincin siginar yayin samun saurin lokaci zuwa kasuwa.Ba da fifikon siginar siginar a duk cikin tsarin samfuri yana tabbatar da samfurin ƙarshe yana aiki da dogaro kuma yana biyan buƙatun masana'antar lantarki ta zamani.

Lokacin aikawa: Oktoba-21-2023

Baya