A cikin 'yan shekarun nan, PCBs masu sassaucin ra'ayi sun zama sananne saboda keɓaɓɓen haɗe-haɗe na sassauci da dorewa. Irin wannan allon kewayawa yana ba masu zanen kaya damar ƙirƙirar sabbin hanyoyin ceton sararin samaniya, musamman a aikace-aikacen da allunan tsattsauran ra'ayi na gargajiya ba za su iya biyan buƙatu ba. Yayin da PCBs masu sassaucin ra'ayi suna ba da damar ƙira iri-iri, har yanzu akwai wasu iyakoki waɗanda ke buƙatar la'akari, musamman game da lanƙwasa radi.

Lanƙwasa radius na PCB shine mafi ƙarancin radius wanda allon zai iya lanƙwasa cikin aminci ba tare da haifar da lahani ga alamu ko abubuwan haɗin gwiwa ba.Don tsayayyen allo, lanƙwasa radius shine maɓalli mai mahimmanci wanda ke shafar gaba ɗaya aiki da amincin allon kewayawa.

Lokacin zana PCB mai tsauri, dole ne ku fahimci iyakokin da radius na lanƙwasa ya sanya.Wuce radiyon lanƙwasa shawarar da aka ba da shawarar na iya haifar da matsaloli kamar lalatawar ganowa, karyewa, ko ma gazawar sassa. Sabili da haka, dole ne a yi la'akari da wannan al'amari a hankali a lokacin ƙirar ƙira don tabbatar da aiki mafi kyau da kuma tsawon lokacin jirgi.

Iyakar radius na lanƙwasa don PCBs masu tsauri ya dogara da abubuwa iri-iri, gami da kayan gini, adadin yadudduka, da kaurin allo gabaɗaya.Bari mu zurfafa zurfafa cikin kowane abu don ƙarin fahimtar tasirinsu:

1. Kayayyakin gini:Zaɓin kayan aiki, kamar kayan tushe da kayan aiki masu sassauƙa da aka yi amfani da su, kai tsaye yana rinjayar iyakar radius na lanƙwasa. Abubuwa daban-daban suna da halaye daban-daban na sassauƙa, wanda ke shafar ƙaramin radius na lanƙwasa. Alal misali, polyimide shine zaɓi na kowa don sassa masu sassauƙa saboda kyakkyawan sassauci da juriya mai zafi. Duk da haka, zaɓin kayan dole ne a daidaita shi a hankali, saboda yin amfani da kayan da ya fi dacewa zai iya haifar da lankwasawa da yawa da yiwuwar lalata allon.

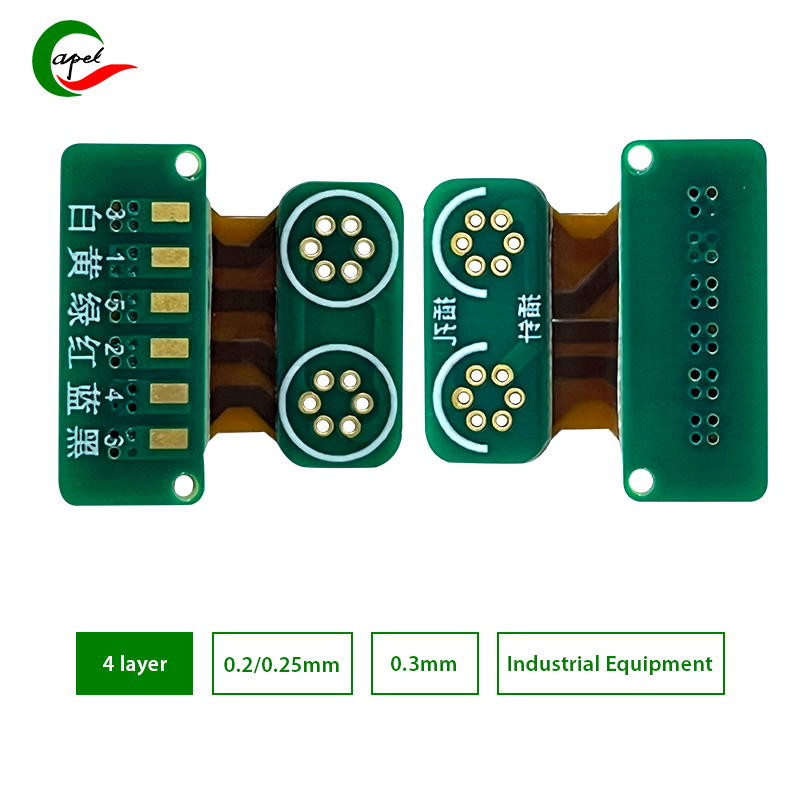

2. Adadin yadudduka:Adadin yadudduka na katako mai tsauri zai shafi iyakar radius na lanƙwasawa. Gabaɗaya magana, ƙarin yadudduka da allo, girman radius na lanƙwasa yana buƙatar zama. Wannan shi ne saboda ƙarin Layer yana gabatar da ƙarin rigidity, yana sa allon ya fi wuya a lanƙwasa ba tare da takura ba ko haifar da wasu matsalolin inji. Masu zanen kaya suyi la'akari da adadin adadin da ake buƙata don takamaiman aikace-aikacen kuma daidaita radius lanƙwasa daidai.

3. Gabaɗaya kauri na farantin:Kaurin farantin kuma yana taka muhimmiyar rawa wajen tantance iyakar radius na lanƙwasa. Mafi ƙanƙanta faranti sun kasance suna da mafi ƙarancin radiyoyin lanƙwasa fiye da faranti masu sirara. Yayin da kaurin allo ke ƙaruwa, kayan ya zama mai ƙarfi, yana buƙatar babban radius na lanƙwasa don guje wa kowane lahani mai yuwuwa.

Lokacin yin la'akari da waɗannan abubuwan da ƙayyade iyakokin sassauƙa don PCBs masu ƙarfi, yana da mahimmanci a yi la'akari da duk wasu abubuwan waje waɗanda zasu iya shafar aikin hukumar.Misali, takamaiman buƙatun aikace-aikacen kamar sassaucin da ake buƙata ko fallasa allon kewayawa zuwa matsanancin yanayin zafi na iya ƙara yin tasiri ga iyakokin radius.

Don tabbatar da mafi kyawun lanƙwasa radi don katako mai sassauƙa, ana ba da shawarar yin aiki tare da ƙwararrun masana'antun da masu zanen kaya waɗanda ke da ilimi da ƙwarewa sosai a wannan fagen.Za su iya ba da basira mai mahimmanci, jagora da goyan baya a cikin tsarin ƙira da masana'antu. Bugu da ƙari, yin amfani da kayan aikin kwaikwayo na ci gaba da yin cikakken gwaji na iya taimakawa wajen tabbatar da zaɓaɓɓen radiyon lanƙwasa da tabbatar da amincin jirgin da tsawon rai.

A taƙaice, ko da yake PCBs masu sassaucin ra'ayi suna ba da damammakin ƙira iri-iri, ana buƙatar la'akari da iyakokin radius ɗin su.Zaɓin kayan gini, adadin yadudduka da kauri na gabaɗaya kai tsaye yana rinjayar iyakar radius na lanƙwasa. Ta hanyar daidaita waɗannan abubuwan a hankali da kuma yin la'akari da takamaiman buƙatun aikace-aikacen, masu ƙira za su iya ƙirƙirar PCB masu ƙarfi da aminci masu ƙarfi waɗanda suka dace da sassaucin da ake buƙata yayin guje wa duk wani matsala mai yuwuwa da suka shafi lankwasawa. Yin aiki tare da ƙwararrun ƙwararrun ƙwararru da yin amfani da kayan aikin siminti na ci gaba na iya sauƙaƙe nasarar ƙirar PCB mai tsauri.

Lokacin aikawa: Satumba-19-2023

Baya