Gabatarwa

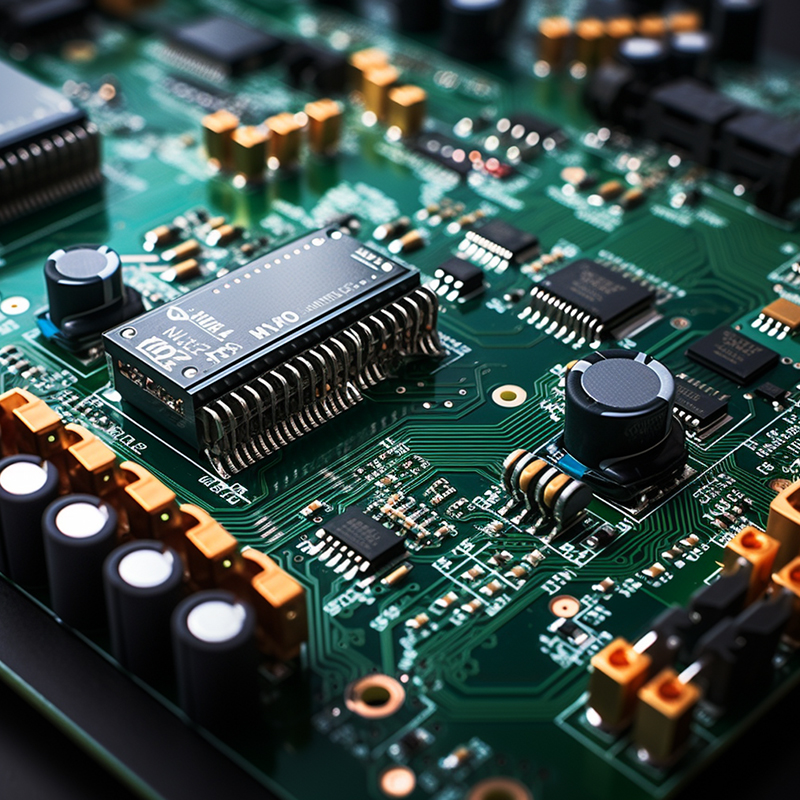

Integrated circuits (ICs) da printed circuit board (PCBs) sune muhimman abubuwa a cikin kayan lantarki na zamani. ICs sun canza yadda ake kera na'urorin lantarki da kera su ta hanyar haɗa abubuwan haɗin lantarki da yawa zuwa guntu ɗaya. A lokaci guda kuma, kunkuntar PCBs suna taka muhimmiyar rawa wajen ba da damar ƙirar na'urar ƙarami da inganci. Wannan labarin zai bincika mahimmancin haɗa ICs tare da kunkuntar PCBs, ƙalubale da fa'idodin da ke tattare da irin wannan haɗin kai, da mafi kyawun ayyuka don zayyana ICs akan kunkuntar PCBs.

Menene hadedde kewaye?

Haɗaɗɗen da'irori, waɗanda galibi ana kiran su microchips ko ICs, ƙananan na'urorin lantarki ne waɗanda aka yi ta hanyar haɗa abubuwa daban-daban na lantarki kamar resistors, capacitors, da transistor akan wafer semiconductor guda ɗaya. Waɗannan abubuwan haɗin gwiwa suna haɗuwa don yin takamaiman ayyuka, suna mai da ICs tubalan ginin na'urorin lantarki. Ana amfani da ICs a cikin aikace-aikace da yawa, gami da wayoyi, kwamfutoci, na'urorin likitanci, da tsarin kera motoci.

Amfanin yin amfani da haɗaɗɗun da'irori suna da girma. Saboda ICs suna da ƙarancin girma, ana iya haɓaka ƙananan na'urorin lantarki da ƙananan. Suna cinye ƙasa da ƙarfi kuma suna haifar da ƙarancin zafi fiye da na'urorin lantarki masu hankali na gargajiya. Bugu da ƙari, ICs suna ba da ƙarin aminci da aiki, yana mai da su wani ɓangare na ƙirar tsarin lantarki na zamani.

Menene allon da'ira bugu kunkuntar?

Wurin da'ira bugu kunkuntar (PCB) PCB ce wacce ke da ƙaramin faɗi fiye da daidaitaccen PCB. PCB wani muhimmin sashi ne na kayan lantarki, yana samar da dandamali don hawa da haɗa abubuwan haɗin lantarki. PCBs masu faɗin kunkuntar suna da mahimmanci don cimma ƙaƙƙarfan ƙira a cikin na'urorin lantarki, musamman a cikin ƙayyadaddun aikace-aikacen sarari.

Muhimmancin ƙirar ƙira a cikin na'urorin lantarki ba za a iya faɗi ba. Yayin da fasaha ke ci gaba da haɓakawa, na'urorin lantarki suna ƙara ƙaranci da ɗaukar nauyi. PCBs masu faɗin kunkuntar suna da mahimmanci don rage girman na'urorin lantarki, yana haifar da ƙarami, ƙarin ƙira ergonomic. Hakanan suna taimakawa haɓaka amincin sigina da rage tsangwama na lantarki a cikin manyan abubuwan lantarki.

Misalin na'urar da ke amfani da kunkuntar allunan da'irar bugu shine sabon ƙarni na wayoyin hannu. Bukatar wayoyi masu salo, masu nauyi masu nauyi sun haifar da haɓakar PCBs masu faɗin kunkuntar waɗanda za su iya ɗaukar haɗaɗɗun kewayawar da ake buƙata don fasalulluka na wayoyin zamani kamar kyamarori masu ƙarfi, haɗin 5G da na'urori masu auna firikwensin.

Haɗin haɗaɗɗun da'irori da kunkuntar PCBs mai faɗi

Haɗin haɗaɗɗun da'irori zuwa PCBs masu faɗin kunkuntar yana ba da fa'idodi da yawa a ƙirar na'urar lantarki. Ta hanyar haɗa ICs tare da kunkuntar PCBs, masu zanen kaya na iya ƙirƙirar haɗaɗɗen tsarin lantarki da adana sarari. Wannan haɗin kai yana raguwamasana'antufarashi, inganta aminci da haɓaka aikin na'urorin lantarki.

Koyaya, zayyana haɗaɗɗun da'irori akan kunkuntar PCBs yana ba da ƙalubale da la'akari da yawa. Masu ƙira suna buƙatar magance batutuwan da suka danganci amincin sigina, sarrafa zafi, da jurewar masana'anta lokacin haɓaka ICs don kunkuntar PCBs. Duk da waɗannan ƙalubalen, fa'idodin haɗa ICs tare da kunkuntar PCBs sun fi rikitarwa, musamman a aikace-aikacen da sarari ke kan ƙima.

Misalai na aikace-aikace inda haɗin IC tare da kunkuntar PCBs ke da mahimmanci sun haɗa da na'urorin da za a iya sawa, dasawa na likita, da tsarin sararin samaniya. A cikin waɗannan aikace-aikacen, ƙayyadaddun ƙima da nauyi suna fitar da buƙatun ƙirar ƙirar lantarki sosai, yana mai da haɗin kai na ICs cikin kunkuntar PCBs mai mahimmanci.

Yadda Ake Zana PCB kunkuntar Nisa Mai Haɗin Kai

Zana haɗaɗɗen da'irori don kunkuntar PCBs na buƙatar cikakken fahimtar ayyuka mafi kyau da dabarun ingantawa. Lokacin haɓaka ICs don kunkuntar PCBs, abubuwan da suka haɗa da ɗimbin motsi, sarrafa zafi, da amincin sigina dole ne a yi la'akari da su. Yin amfani da kayan aikin ƙira na ci gaba da fasaha na kwaikwayo na iya taimakawa wajen inganta tsarin haɗin kai da kuma tabbatar da aminci da aikin haɗin gwiwar tsarin lantarki.

Nazarin shari'ar ƙirar ƙirar IC mai nasara akan PCBs kunkuntar yana nuna mahimmancin haɗin gwiwa tsakanin masu zanen IC, masu zanen PCB, damasana'antun. Ta hanyar yin aiki tare, waɗannan ƙungiyoyi za su iya ganowa da warware ƙalubalen ƙira a farkon tsarin ci gaba, wanda ya haifar da haɗin kai mai nasara da kuma ingantaccen tsarin lantarki.

A karshe

A taƙaice, haɗa haɗin haɗaɗɗun da'irori tare da kunkuntar allon buga bugu yana taka muhimmiyar rawa wajen ƙirar na'urorin lantarki na gaba. Yayin da buƙatun mabukaci na ƙarami, ingantattun na'urorin lantarki ke ci gaba da haɓaka, buƙatar haɗaɗɗun tsarin lantarki da adana sararin samaniya ya zama sananne sosai. Ta hanyar ɗaukar mafi kyawun ayyuka da dabarun haɓakawa don kunkuntar ƙirar PCB IC, masu zanen lantarki za su iya kasancewa gaba da gaba kuma suna samar da sabbin hanyoyin magance canjin canjin kasuwa.

Makomar haɗaɗɗen ƙirar da'ira ta ta'allaka ne a cikin haɗin kai mara kyau na ICs cikin kunkuntar PCBs, yana ba da damar haɓaka na'urorin lantarki na gaba waɗanda ke da ƙarfi, ingantaccen makamashi, da babban aiki. Don taimakon ƙwararru tare da kunkuntar ƙirar PCB da haɗin kai na haɗaɗɗun da'irori, tuntuɓi ƙungiyar ƙwararrun ƙwararrunmu. Mun himmatu don taimaka muku samun mafi kyawun ƙirar kayan lantarki ta hanyar fasaha mai ƙima da haɗin gwiwa.

A taƙaice, haɗa haɗin haɗaɗɗun da'irori tare da kunkuntar allon buga bugu yana da mahimmanci ga makomar ƙirar na'urar lantarki. Ta hanyar ɗaukar mafi kyawun ayyuka da dabarun ingantawa a cikin ƙirar IC don kunkuntar PCBs, masu zanen lantarki na iya ƙirƙirar sabbin hanyoyin magance canjin canjin kasuwa. Idan kuna buƙatar taimakon ƙwararru tare da ƙira da haɗin kai na kunkuntar PCBs don haɗaɗɗun da'irori, tuntuɓi ƙungiyarmu don jagorar ƙwararru. Mun himmatu don taimaka muku samun mafi kyawun ƙirar kayan lantarki ta hanyar fasaha mai ƙima da haɗin gwiwa.

Lokacin aikawa: Janairu-05-2024

Baya