Delamination a cikin PCB na iya haifar da mahimman al'amurran da suka shafi aiki, musamman a cikin ƙira mai ƙarfi-sauƙi inda aka haɗa duka m da sassauƙan kayan. Fahimtar yadda za a hana delamination yana da mahimmanci don tabbatar da tsawon rai da amincin waɗannan hadaddun taruka. Wannan labarin zai bincika shawarwari masu amfani don hana lalata PCB, mai da hankali kan lamination na PCB, dacewa da kayan aiki, da ingantattun sigogin injina.

Fahimtar Delamination PCB

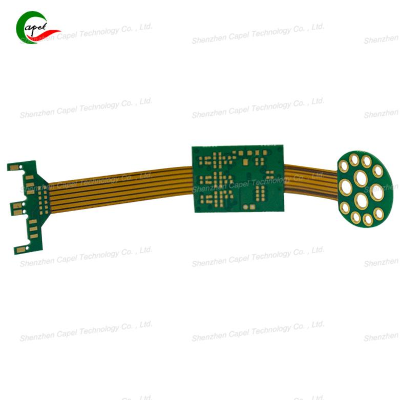

Delamination yana faruwa lokacin da yadudduka na PCB ya rabu saboda dalilai daban-daban, gami da damuwa na zafi, shayar da danshi, da nau'in inji. A cikin PCBs masu sassaucin ra'ayi, ƙalubalen yana ƙaruwa saboda bambancin kaddarorin masu ƙarfi da sassauƙa. Don haka, tabbatar da dacewa tsakanin waɗannan kayan shine matakin farko na hana lalatawa.

Tabbatar da dacewa da Kayan PCB

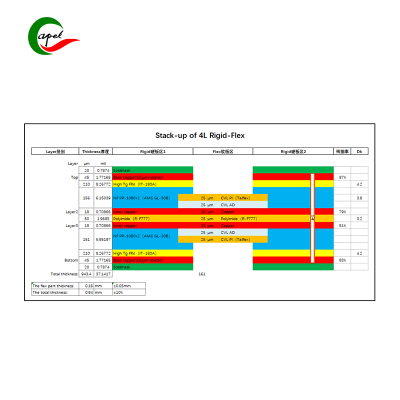

Zaɓin kayan yana da mahimmanci don hana lalatawa. Lokacin zayyana PCB mai tsauri, yana da mahimmanci don zaɓar kayan da ke da nau'ikan haɓaka haɓakar zafi iri ɗaya. Wannan dacewa yana rage damuwa yayin hawan keken zafi, wanda zai iya haifar da delamination. Bugu da ƙari, yi la'akari da abin da aka yi amfani da shi a cikin tsarin lamination. Maɗaukaki masu inganci waɗanda aka ƙera musamman don aikace-aikacen sassauƙa mai ƙarfi na iya haɓaka ƙarfin haɗin gwiwa sosai tsakanin yadudduka.

PCB Lamination Tsari

Tsarin lamination mataki ne mai mahimmanci a masana'antar PCB. Daidaitaccen lamination yana tabbatar da cewa yadudduka suna manne da juna sosai, yana rage haɗarin delamination. Anan akwai wasu shawarwari masu amfani don ingantaccen lamination PCB:

Zazzabi da Kula da Matsi: Tabbatar cewa an gudanar da tsarin lamination a daidai zafin jiki da matsa lamba. Yawan zafin jiki da yawa na iya lalata kayan, yayin da rashin isasshen matsa lamba zai iya haifar da rashin daidaituwa.

Vacuum Lamination: Yin amfani da vacuum yayin aikin lamination zai iya taimakawa wajen kawar da kumfa na iska wanda zai iya haifar da rauni a cikin haɗin gwiwa. Wannan dabarar tana tabbatar da ƙarin matsi iri ɗaya a cikin yadudduka na PCB.

Lokacin MaganiBada isassun lokacin warkewa don mannen ya haɗa daidai. Yin gaggawar wannan tsari na iya haifar da mannewa da bai cika ba, yana ƙara haɗarin delamination.

Ingantattun Ma'aunin Injin PCB-Flex

Siffofin injina suna taka muhimmiyar rawa a cikin amincin PCBs masu sassaucin ra'ayi. Anan akwai ingantattun shawarwarin injina don hana delamination:

Dabarun hakowa: Yi amfani da raƙuman rawar soja da suka dace da sauri don rage haɓakar zafi yayin aikin hakowa. Yawan zafi zai iya raunana haɗin gwiwa kuma ya haifar da lalata.

Hanyar hanya da Yankewa: Lokacin tuƙi ko yanke PCB, tabbatar da cewa kayan aikin suna da kaifi kuma suna da kyau. Kayan aiki maras ban sha'awa na iya haifar da matsananciyar matsa lamba da zafi, yana lalata amincin yadudduka.

Jiyya na Edge: Yi maganin gefuna na PCB da kyau bayan yin injin. Wannan na iya haɗawa da sassauƙa ko rufe gefuna don hana shigar danshi, wanda zai iya ba da gudummawa ga lalatawa cikin lokaci.

Nasihu masu Aiki don Hana Delamination na PCB

Baya ga dabarun da ke sama, yi la'akari da shawarwari masu amfani masu zuwa:

Kula da Muhalli: Ajiye PCBs a cikin yanayi mai sarrafawa don hana ɗaukar danshi. Danshi na iya raunana haɗin gwiwa kuma ya haifar da lalacewa.

Gwaji akai-akai: Aiwatar da gwaje-gwaje na yau da kullun na PCBs don alamun delamination yayin aikin masana'anta. Ganowa da wuri zai iya taimakawa wajen rage al'amura kafin su ta'azzara.

Horo da Fadakarwa: Tabbatar cewa duk ma'aikatan da ke da hannu a cikin tsarin masana'antar PCB an horar da su a mafi kyawun ayyuka don lamination da machining. Sanin abubuwan da ke haifar da delamination na iya haifar da mafi kyawun yanke shawara.

Lokacin aikawa: Oktoba-31-2024

Baya