Idan ya zo ga PCBs masu sassauƙa (allon da'irar bugu), ɗayan mahimman abubuwan da za a yi la'akari da su shine kaurin jan ƙarfe. Copper yana taka muhimmiyar rawa a cikin ayyuka da dorewa na PCBs masu sassauƙa kuma saboda haka muhimmin al'amari ne don fahimta.A cikin wannan blog post, za mu zurfafa zurfin cikin topic na jan karfe kauri a m PCBs, da Shenzhen Capel Technology Co., Ltd. goyon bayan jan bakin ciki, tattauna muhimmancinsa da kuma yadda shi rinjayar da overall yi na hukumar.

Muhimmancin kauri na jan ƙarfe a cikin PCB mai sassauƙa

Copper shine zaɓi na farko don PCBs saboda kyakkyawan ingancin wutar lantarki da juriya na lalata.A cikin PCBs masu sassauƙa, ana amfani da jan ƙarfe azaman kayan aiki wanda ke ba da damar wutar lantarki ta gudana ta cikin kewaye. Kaurin jan ƙarfe kai tsaye yana rinjayar aiki da aiki na PCB mai sassauƙa. Ga dalilin da yasa kauri tagulla ke da mahimmanci:

1. Ƙarfin ɗauka na Yanzu: Kaurin jan ƙarfe yana ƙayyade nawa PCB zai iya ɗauka ba tare da zafi ba ko haifar da matsalolin lantarki.Yaduddukan tagulla masu kauri na iya sarrafa igiyoyin ruwa masu tsayi yadda ya kamata, yana tabbatar da aikin da'ira mai sassauƙa.

2. Mutuncin sigina: Ana amfani da PCB masu sassauƙa sau da yawa a aikace-aikacen da ke buƙatar ingantaccen sigina, kamar sararin samaniya, kayan aikin likita, da sadarwa.Kaurin tagulla yana rinjayar ƙunshewar alamar, yana tabbatar da cewa sigina suna yaduwa daidai tare da ƙarancin asara ko murdiya.

3. Ƙarfin Mechanical: An tsara allunan da'ira masu sassauƙa don zama masu sassauƙa, wanda ke nufin suna fuskantar kullun lanƙwasa, karkatarwa da sassauƙa.Layin jan ƙarfe yana ba da ƙarfin injina zuwa kewaye kuma yana hana fasa ko karyewa a cikin hanyoyin gudanarwa. Isasshen kauri na jan karfe yana tabbatar da cewa PCB ya kasance mai ƙarfi da ɗorewa duk tsawon rayuwarsa.

Koyi game da auna kaurin jan karfe

A cikin duniyar PCB mai sassauƙa, ana auna kauri tagulla a cikin oza a kowace ƙafar murabba'in (oz/ft²) ko micrometers (μm). Mafi yawan zaɓuɓɓukan kauri na jan ƙarfe don PCB masu sassauƙa sune 0.5 oz (17.5 µm), 1 oz (35 µm), 2 oz (70 µm), da 3 oz (105 µm). Zaɓin kauri na jan ƙarfe ya dogara da takamaiman buƙatun aikace-aikacen kamar ƙarfin ɗaukar nauyi da ƙarfin injina.

Abubuwan da ke shafar zaɓin kauri na jan karfe

Abubuwa da yawa suna rinjayar zaɓin kauri na jan ƙarfe a cikin PCB mai sassauƙa, gami da:

1. Abubuwan buƙatu na yanzu: Manyan aikace-aikace na yanzu yawanci suna buƙatar yadudduka mai kauri don tabbatar da ingantattun ƙarfin ɗaukar halin yanzu.Dole ne a yi la'akari da iyakar halin yanzu da da'irar za ta ci karo da ita don guje wa zafi da jan ƙarfe ko jujjuyawar wutar lantarki.

2. Matsalolin sararin samaniya: Ƙananan, ƙananan na'urori na iya buƙatar ƙananan yadudduka na jan karfe don dacewa da iyakataccen sararin samaniya.Koyaya, yakamata a auna wannan shawarar a hankali akan ƙarfin ɗaukar nauyi da buƙatun ƙarfin injina.

3. Sassauci: Matsalolin PCB yana shafar kauri na jan karfe.Yadukan tagulla masu kauri yawanci suna da wahala, suna rage juzu'in da'irar gabaɗaya. Don aikace-aikacen sassauƙa sosai, ƙananan kauri na tagulla an fi so.

Kariyar masana'anta

PCB masu sassaucin ra'ayi an tsara su don ɗaukar nau'ikan kaurin tagulla. Koyaya, wasu kaurin jan ƙarfe na iya buƙatar ƙarin taka tsantsan ko fasaha na musamman yayin aikin masana'anta. Yadukan tagulla masu kauri na iya buƙatar tsawon lokacin etching don cimma tsarin da'irar da ake so, yayin da ƙananan yadudduka na jan ƙarfe na buƙatar ƙarin aiki mai laushi don guje wa lalacewa yayin haɗuwa.

Yin aiki tare da ƙera PCB yana da mahimmanci don fahimtar kowane iyakance ko la'akari da ƙayyadaddun kauri da ake buƙata. Wannan yana tabbatar da ingantaccen tsarin masana'anta ba tare da shafar aikin PCB ba.

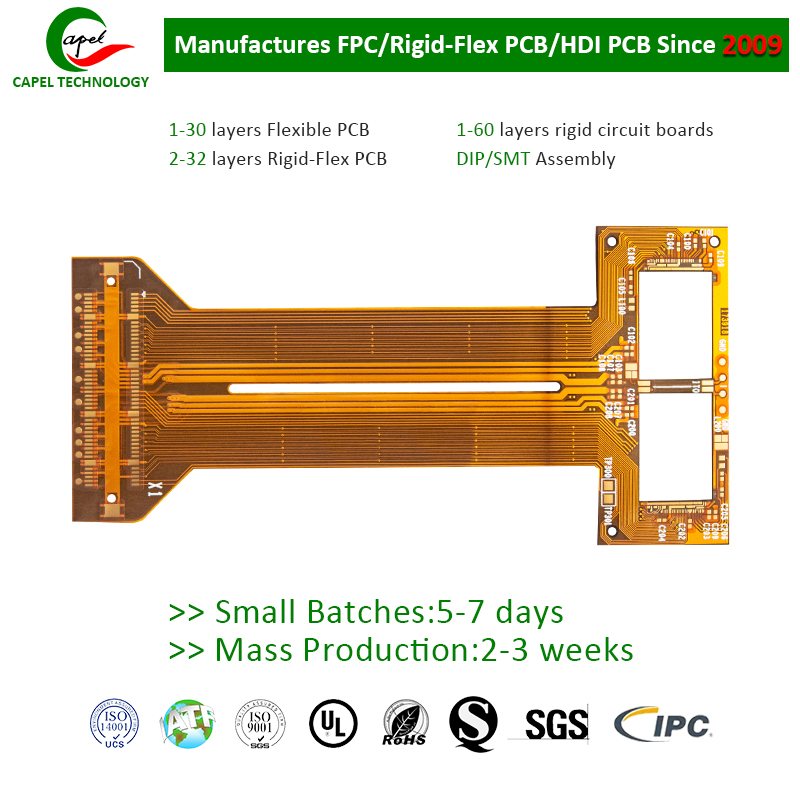

Shenzhen Capel Technology Co., Ltd. yana goyan bayan bakin ciki na jan karfe a cikin pcb m

Capel sanannen kamfani ne wanda ya ƙware a cikin kera kwalayen da'ira masu sassauƙa kuma ya fahimci mahimmancin kauri na jan ƙarfe zuwa aikin gabaɗaya da aikin kwamfutoci masu sassauƙa. Suna ba da zaɓuɓɓuka masu yawa don dacewa da buƙatu daban-daban da ƙayyadaddun bayanai.

Daidaitaccen kewayawa mai sassauƙa:

Don daidaitattun da'irori masu sassauƙa, Capel yana ba da zaɓuɓɓukan kauri iri-iri na jan karfe. Waɗannan sun haɗa da 9um, 12um, 18um, 35um, 70um, 100um da 140um. Samar da zaɓuɓɓuka masu yawa yana ba abokan ciniki damar zaɓar kaurin jan ƙarfe mai dacewa don takamaiman bukatun su. Ko kuna buƙatar ƙaramin jan ƙarfe mai sirara don ƙarin aikace-aikace masu sassauƙa ko kauri mai kauri don ingantaccen dorewa, Capel yana da abin da kuke buƙata.

Lebur m kewaye:

Capel kuma yana ba da da'irori masu sassaucin ra'ayi tare da kaurin jan ƙarfe daban-daban. Kauri na jan karfe na waɗannan da'irori yana daga 0.028mm zuwa 0.1mm. Ana amfani da waɗannan siraran siraran da'irori masu sassauƙa sau da yawa a cikin aikace-aikacen da ke da iyaka inda ba za a iya amfani da tsayayyen PCB na gargajiya ba. Ikon keɓance kaurin jan ƙarfe yana tabbatar da cewa waɗannan da'irori za su iya biyan buƙatun ƙira na na'urorin lantarki iri-iri.

Da'irar mai sassauƙa mai ƙarfi:

Baya ga da'irori masu sassauƙa, Capel kuma ya ƙware a da'irori masu ƙarfi. Waɗannan da'irori sun haɗu da fa'idodin PCBs masu ƙarfi da sassauƙa, suna sa su dace don aikace-aikacen da ke buƙatar aminci da sassauci. Ana samun Capel a cikin 1/2 oz kauri na jan karfe. Ayyukan da'irar sa mai tsauri ya fi girma. Wannan yana bawa da'ira damar saduwa da buƙatun ƙaƙƙarfan aikace-aikace yayin da ake kiyaye sassaucin da ya dace.

Canjin gabobin jiki:

Har ila yau, Capel yana samar da maɓallan membrane tare da yadudduka na tagulla na musamman. Ana amfani da waɗannan maɓallan a ko'ina a cikin masana'antu waɗanda ke buƙatar mafita mai amfani, kamar kayan aikin likita da tsarin sarrafa masana'antu. Kaurin jan ƙarfe na waɗannan maɓallan musanya ya bambanta daga 0.005 ″ zuwa 0.0010 ″. Ƙarƙashin baƙin ƙarfe na jan karfe yana tabbatar da sauyawa yana da matukar amsa yayin da yake kiyaye dorewa mai mahimmanci.

Tunani Na Ƙarshe:

Kaurin jan ƙarfe a cikin PCB mai sassauƙa yana da tasiri mai mahimmanci akan aikin sa, amintacce da tsawon rai. Zaɓin kauri mai dacewa da tagulla dangane da buƙatun yanzu, ƙayyadaddun sararin samaniya, sassauci da la'akari da masana'anta yana da mahimmanci. Tuntuɓar ƙwararrun masana'antun PCB da ƙwararrun ƙira na iya taimakawa haɓaka PCB masu sassauƙa don aikace-aikace daban-daban, tabbatar da sun cika ka'idojin aikin lantarki da na inji da ake buƙata.

Capel babban mai samar da allunan da'ira mai sassauƙa, yana ba da zaɓuɓɓukan kauri iri-iri don biyan buƙatu daban-daban. Ko kuna buƙatar daidaitattun da'irori masu sassauƙa, da'irar lallausan sassauƙa, tsattsauran raɗaɗin sassauƙa ko maɓalli, Capel yana da ƙwarewa da iyawa don sadar da samfura masu inganci tare da kaurin jan ƙarfe da ake buƙata. Ta yin aiki tare da Capel, za ku iya tabbatar da PCB ɗin ku mai sassauƙa ya dace da ƙa'idodin da ake buƙata kuma yana aiki da kyau a aikace-aikacenku.

Lokacin aikawa: Oktoba-11-2023

Baya