Wannan labarin zai samar da wani m bayyani na surface jiyya tsari ga FPC Flex PCB masana'antu. Daga mahimmancin shirye-shiryen shimfidar wuri zuwa hanyoyi daban-daban na rufi, za mu rufe mahimman bayanai don taimaka muku fahimta da aiwatar da tsarin shirye-shiryen saman yadda ya kamata.

Gabatarwa:

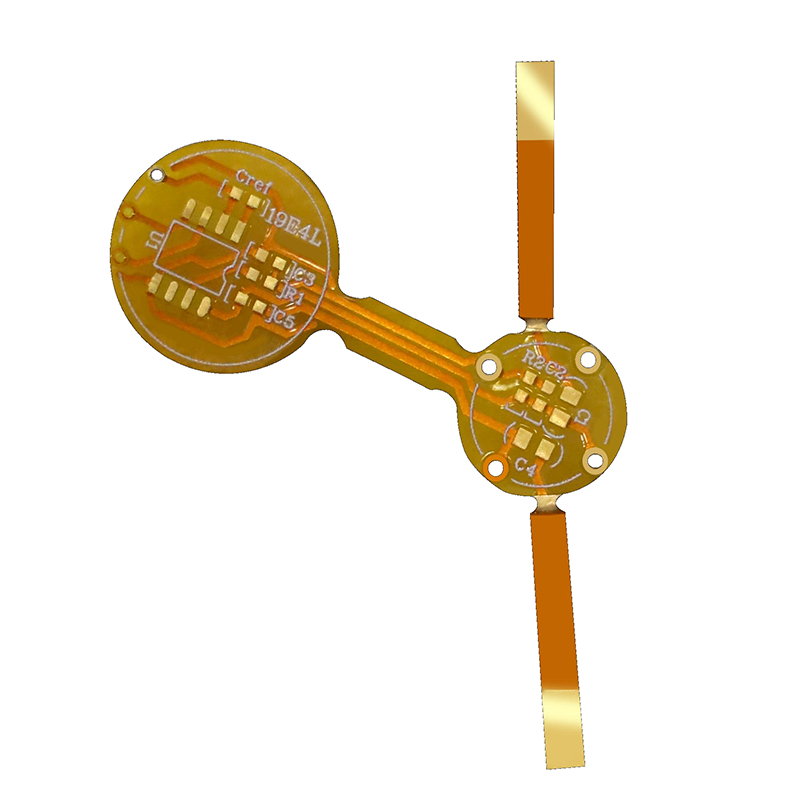

PCBs masu sassaucin ra'ayi (Alamomin da'ira masu sassauƙa) suna samun karɓuwa a cikin masana'antu daban-daban saboda iyawarsu da iya daidaitawa zuwa hadaddun siffofi. Ayyukan shirye-shiryen saman suna taka muhimmiyar rawa wajen tabbatar da ingantaccen aiki da amincin waɗannan da'irori masu sassauƙa. Wannan labarin zai samar da wani m bayyani na surface jiyya tsari ga FPC Flex PCB masana'antu. Daga mahimmancin shirye-shiryen shimfidar wuri zuwa hanyoyi daban-daban na rufi, za mu rufe mahimman bayanai don taimaka muku fahimta da aiwatar da tsarin shirye-shiryen saman yadda ya kamata.

Abubuwan da ke ciki:

1. Muhimmancin jiyya na sama a cikin masana'antar FPC mai sassauƙa ta PCB:

Maganin saman yana da mahimmanci a cikin masana'antar FPC masu sassaucin ra'ayi kamar yadda yake hidima da dalilai da yawa. Yana sauƙaƙe soldering, yana tabbatar da mannewa mai kyau, kuma yana kare abubuwan da ke gudana daga iskar shaka da lalata muhalli. Zaɓin da ingancin jiyya na saman kai tsaye yana rinjayar dogaro da cikakken aikin PCB.

Ƙarshen saman ƙasa a masana'antar FPC Flex PCB yana ba da dalilai masu mahimmanci da yawa.Na farko, yana sauƙaƙe soldering, yana tabbatar da haɗin kai na kayan lantarki zuwa PCB. Jiyya na saman yana haɓaka solderability don haɗin gwiwa mai ƙarfi da aminci tsakanin ɓangaren da PCB. Ba tare da shirye-shiryen da ya dace ba, haɗin gwiwar solder na iya zama mai rauni kuma mai saurin gazawa, yana haifar da rashin aiki da yuwuwar lalacewa ga dukkan kewaye.

Wani muhimmin al'amari na shirye-shiryen saman a cikin masana'antar FPC Flex PCB yana tabbatar da kyakkyawan mannewa.FPC masu sassaucin ra'ayi PCBs sukan fuskanci matsananciyar lankwasawa da sassauya yayin rayuwar sabis ɗin su, wanda ke sanya damuwa akan PCB da abubuwan haɗin sa. Jiyya na saman yana ba da kariya ta kariya don tabbatar da cewa ɓangaren yana manne da PCB, yana hana yiwuwar ɓarna ko lalacewa yayin sarrafawa. Wannan yana da mahimmanci musamman a aikace-aikace inda damuwa na inji ko girgiza ya zama ruwan dare.

Bugu da ƙari, jiyya na saman yana kare alamun gudanarwa akan FPC Flex PCB daga oxidation da lalata muhalli.Waɗannan PCBs koyaushe ana fallasa su ga abubuwan muhalli daban-daban kamar zafi, canjin zafin jiki da sinadarai. Idan ba tare da isassun shirye-shiryen ƙasa ba, alamun da ke gudana na iya lalacewa cikin lokaci, haifar da gazawar lantarki da gazawar kewaye. Maganin saman yana aiki azaman shamaki, yana kare PCB daga muhalli da haɓaka rayuwar sa da amincinsa.

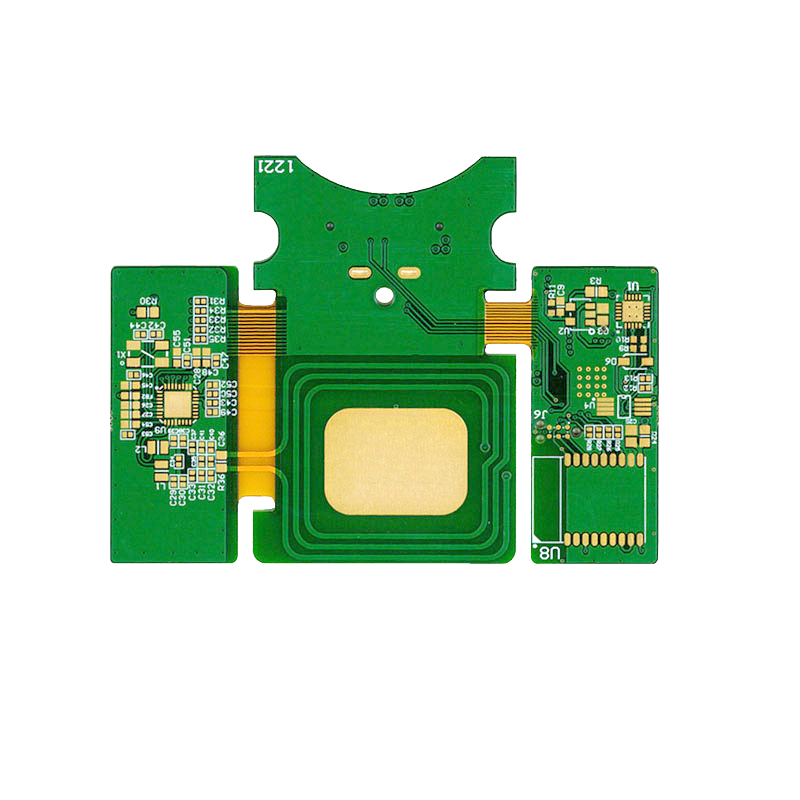

2.Common surface jiyya hanyoyin for FPC flex PCB masana'antu:

Wannan sashe zai tattauna dalla-dalla hanyoyin da ake amfani da su dalla-dalla a cikin hanyoyin da aka fi amfani da su a cikin masana'anta masu sassaucin ra'ayi na FPC, gami da Hot Air Solder Leveling (HASL), Electroless Nickel Immersion Gold (ENIG), Organic Solderability Preservative (OSP), Immersion Tin (ISn) da lantarki. (E-plating). Kowace hanya za a bayyana tare da amfaninta da rashin amfaninta.

Matsayin Solder Air Hot Air (HASL):

HASL wata hanya ce ta jiyya ta saman da aka yi amfani da ita saboda tasiri da ƙimar farashi. Tsarin ya ƙunshi lulluɓe saman tagulla tare da Layer na solder, wanda sai a yi zafi da iska mai zafi don ƙirƙirar ƙasa mai santsi. HASL yana ba da ingantaccen solderability kuma yana dacewa da nau'ikan sassa iri-iri da hanyoyin siyarwa. Koyaya, yana kuma da iyakoki kamar ƙarewar ƙasa mara daidaituwa da yuwuwar lalacewa ga alamomi masu laushi yayin sarrafawa.

Nickel Immersion Gold (ENIG):

ENIG sanannen zaɓi ne a cikin masana'antar da'ira mai sassauƙa saboda ingantaccen aiki da amincin sa. Wannan tsari ya hada da sanya wani siririn nickel a saman saman tagulla ta hanyar sinadarai, sannan a nutsar da shi a cikin maganin electrolyte mai dauke da gwal. ENIG yana da kyakkyawan juriya na lalata, rarraba kauri iri ɗaya da ingantaccen solderability. Duk da haka, babban farashin da ke da alaƙa da tsari da kuma yuwuwar al'amurran da suka shafi baƙar fata suna daga cikin abubuwan da za a yi la'akari da su.

Ƙwararren Solderability Preservative (OSP):

OSP wata hanya ce ta jiyya da ke tattare da rufe saman jan karfe tare da fim na bakin ciki na kwayoyin don hana shi daga iskar oxygen. Wannan tsari yana da alaƙa da muhalli saboda yana kawar da buƙatar ƙarfe mai nauyi. OSP yana samar da fili mai lebur da ingantaccen solderability, yana mai da shi dacewa da kayan aikin farar kyau. Koyaya, OSP yana da ƙayyadaddun rayuwar shiryayye, yana da kula da mu'amala, kuma yana buƙatar ingantaccen yanayin ajiya don kiyaye ingancinsa.

Tin Immersion (ISn):

ISn hanya ce ta maganin saman da ta ƙunshi nutsar da da'ira mai sassauƙa a cikin wanka na narkakkar gwangwani. Wannan tsari yana samar da wani bakin ciki na tin a saman jan karfe, wanda ke da kyakkyawan solderability, flatness da juriya na lalata. ISn yana ba da ƙaƙƙarfan ƙarewa mai santsi wanda ya sa ya dace don aikace-aikacen farar mai kyau. Duk da haka, yana da iyakacin juriya na zafi kuma yana iya buƙatar kulawa ta musamman saboda karyewar kwano.

Electroplating (E plating):

Electroplating hanya ce ta jiyya ta gama gari a cikin masana'anta masu sassauƙa. Tsarin ya ƙunshi saka wani Layer na ƙarfe akan saman jan ƙarfe ta hanyar amsawar lantarki. Dangane da buƙatun aikace-aikacen, ana samun electroplating a cikin zaɓuɓɓuka iri-iri kamar zinariya, azurfa, nickel ko plating na kwano. Yana bayar da kyakkyawan karko, solderability da juriya na lalata. Koyaya, yana da ƙarancin tsada idan aka kwatanta da sauran hanyoyin jiyya na saman kuma yana buƙatar kayan aiki masu rikitarwa da sarrafawa.

3.Trecautions ga zabar daidai surface jiyya hanya a FPC flex PCB masana'antu:

Zaɓin madaidaicin saman gama don FPC sassauƙan da'irori yana buƙatar yin la'akari da hankali na abubuwa daban-daban kamar aikace-aikacen, yanayin muhalli, buƙatun solderability, da ingancin farashi. Wannan sashe zai ba da jagora kan zaɓar hanyar da ta dace bisa waɗannan la'akari.

Sanin bukatun abokan ciniki:

Kafin zurfafa cikin jiyya daban-daban da ake da su, yana da mahimmanci a sami cikakkiyar fahimtar bukatun abokan ciniki. Yi la'akari da abubuwa masu zuwa:

Aikace-aikace:

Ƙayyade aikace-aikacen da aka yi niyya na PCB ɗin FPC ɗin ku mai sassauƙa. Shin don kayan lantarki na mabukaci, motoci, likita ko kayan masana'antu? Kowace masana'antu na iya samun takamaiman buƙatu, kamar juriya ga yanayin zafi, sinadarai ko damuwa na inji.

Yanayin Muhalli:

Yi la'akari da yanayin muhalli da PCB zai fuskanta. Za a iya fallasa shi ga danshi, zafi, matsanancin zafi ko abubuwa masu lalata? Wadannan abubuwan zasu tasiri hanyar shirye-shiryen saman don samar da mafi kyawun kariya daga iskar shaka, lalata da sauran lalacewa.

Bukatun solderability:

Yi nazarin buƙatun solderability na FPC m PCB. Hukumar za ta bi ta hanyar siyar da igiyar igiyar ruwa ko kuma ta sake fitar da siyar? Daban-daban jiyya na saman suna da jituwa daban-daban tare da waɗannan dabarun walda. Yin la'akari da wannan zai tabbatar da abin dogara ga haɗin gwiwar solder da kuma hana matsaloli irin su lahani da kuma buɗewa.

Bincika Hanyoyin Maganin Sama:

Tare da cikakkiyar fahimtar bukatun abokan ciniki, lokaci ya yi da za a bincika jiyya na saman da ke akwai:

Ƙwararren Solderability Preservative (OSP):

OSP sanannen wakili ne na jiyya na sama don FPC m PCB saboda ingancin farashi da halayen kariyar muhalli. Yana bayar da wani bakin ciki mai kariya Layer wanda ya hana hadawan abu da iskar shaka da kuma sauƙaƙe soldering. Koyaya, OSP na iya samun ƙayyadaddun kariya daga mahalli masu tsauri da ɗan gajeren rayuwa fiye da sauran hanyoyin.

Nickel Immersion Gold (ENIG):

Ana amfani da ENIG ko'ina a cikin masana'antu daban-daban saboda kyakkyawan solderability, juriya da lalata. Gilashin zinari yana tabbatar da haɗin gwiwa mai dogara, yayin da nickel Layer yana samar da kyakkyawan juriya na iskar shaka da kariyar yanayi. Koyaya, ENIG yana da ɗan tsada idan aka kwatanta da sauran hanyoyin.

Wutar Zinare Mai Wuya (Zinari mai Wuya):

Zinariya mai wuya yana da ɗorewa kuma yana ba da ingantaccen amincin tuntuɓar sadarwa, yana sa ya dace da aikace-aikacen da suka haɗa da maimaita shigarwa da yanayin lalacewa. Koyaya, shine zaɓin gamawa mafi tsada kuma ƙila ba za'a buƙaci kowane aikace-aikace ba.

Nickel Electroless Palladium Immersion Gold (ENEPIG):

ENEPIG wakili ne na jiyya mai aiki da yawa wanda ya dace da aikace-aikace daban-daban. Yana haɗu da fa'idodin nickel da yadudduka na gwal tare da ƙarin fa'ida na Layer palladium matsakaici, yana ba da kyakkyawar haɗin waya da juriya na lalata. Koyaya, ENEPIG yana ƙoƙarin zama mafi tsada da rikitarwa don sarrafawa.

4.Comprehensive mataki-by-mataki Jagora ga Surface Shirye matakai a FPC m PCB masana'antu:

Don tabbatar da nasarar aiwatar da matakan shirye-shiryen saman, yana da mahimmanci a bi tsarin tsari. Wannan sashe zai ba da cikakken jagorar mataki-mataki wanda ya ƙunshi pretreatment, tsaftacewa sinadarai, aikace-aikacen juzu'i, suturar ƙasa da hanyoyin jiyya. An bayyana kowane mataki sosai, yana nuna dabarun da suka dace da mafi kyawun ayyuka.

Mataki 1: Gabatarwa

Pretreatment shine mataki na farko a shirye-shiryen saman kuma ya haɗa da tsaftacewa da cire gurɓataccen ƙasa.

Da farko duba saman don kowane lalacewa, lahani ko lalata. Dole ne a warware wadannan batutuwa kafin a dauki wani mataki na gaba. Na gaba, yi amfani da matsewar iska, goga, ko vacuum don cire duk wani sako-sako da barbashi, ƙura, ko datti. Don ƙarin gurɓataccen gurɓataccen abu, yi amfani da kaushi ko mai tsabtace sinadari wanda aka tsara musamman don kayan saman. Tabbatar cewa saman ya bushe sosai bayan tsaftacewa, saboda ragowar danshi na iya hana matakai na gaba.

Mataki 2: Tsabtace Sinadarai

Tsaftace sinadarai ya ƙunshi cire duk wani gurɓataccen abu daga saman.

Zaɓi sinadari mai tsabta mai dacewa dangane da kayan da ke saman da nau'in gurɓatawa. Aiwatar da mai tsabta a ko'ina zuwa saman kuma ba da damar isasshen lokacin tuntuɓar don cirewa mai inganci. Yi amfani da goga ko goge goge don goge saman a hankali, kula da wuraren da ke da wuyar isa. Kurkura saman sosai da ruwa don cire duk wani abin da ya rage na mai tsabta. Tsarin tsaftace sinadarai yana tabbatar da cewa saman yana da tsabta kuma yana shirye don aiki na gaba.

Mataki 3: Flux Application

Aikace-aikacen juyi yana da mahimmanci ga tsarin brazing ko siyar da shi yayin da yake haɓaka mafi kyawun mannewa kuma yana rage oxidation.

Zaɓi nau'in juzu'i mai dacewa bisa ga kayan da za a haɗa da ƙayyadaddun buƙatun tsari. Aiwatar da juzu'i a ko'ina zuwa yankin haɗin gwiwa, yana tabbatar da cikakken ɗaukar hoto. Yi hankali kada a yi amfani da wuce gona da iri domin yana iya haifar da matsalolin siyarwa. Ya kamata a yi amfani da ruwa nan da nan kafin aikin siyar da siyar da shi don kiyaye ingancin sa.

Mataki na 4: Rufin Sama

Rubutun saman yana taimakawa kare saman daga yanayin muhalli, hana lalata da haɓaka kamanninsu.

Kafin yin amfani da sutura, shirya bisa ga umarnin masana'anta. Aiwatar da rigar a hankali ta yin amfani da goga, abin nadi ko feshi, yana tabbatar da ɗaukar hoto daidai da santsi. Lura da shawarar bushewa ko lokacin warkewa tsakanin riguna. Don sakamako mafi kyau, kula da ingantaccen yanayin muhalli kamar yanayin zafi da yanayin zafi yayin warkewa.

Mataki na 5: Bayan aiwatarwa

Tsarin bayan magani yana da mahimmanci don tabbatar da tsayin daka na rufin rufin da kuma cikakken ingancin da aka shirya.

Bayan murfin ya warke sosai, bincika kowane lahani, kumfa ko rashin daidaituwa. Gyara waɗannan matsalolin ta hanyar yashi ko goge saman, idan ya cancanta. Kulawa na yau da kullun da dubawa suna da mahimmanci don gano duk wani alamun lalacewa ko lalacewa a cikin suturar ta yadda za'a iya gyara shi da sauri ko sake yin amfani da shi idan an buƙata.

5.Quality Control da Testing a FPC m PCB masana'antu surface jiyya tsari:

Kula da ingancin inganci da gwaji suna da mahimmanci don tabbatar da ingancin hanyoyin shirye-shiryen saman. Wannan sashe zai tattauna hanyoyin gwaji daban-daban, gami da dubawa na gani, gwajin mannewa, gwajin solderability, da gwajin dogaro, don tabbatar da daidaiton inganci da amincin masana'antar FPC Flex PCBs da ake bi da su.

Duban gani:

Binciken gani mataki ne na asali amma muhimmin mataki a kula da inganci. Ya haɗa da duba saman PCB na gani don kowane lahani kamar karce, oxidation ko gurɓatawa. Wannan binciken na iya amfani da kayan aikin gani ko ma na'ura mai gani da ido don gano duk wani abu mara kyau wanda zai iya shafar aikin PCB ko amintacce.

Gwajin Adhesion:

Ana amfani da gwajin mannewa don kimanta ƙarfin mannewa tsakanin jiyya ko shafi da abin da ke ƙasa. Wannan gwajin yana tabbatar da cewa ƙarshen yana da alaƙa da PCB, yana hana duk wani ɓarke da wuri. Dangane da ƙayyadaddun buƙatu da ƙa'idodi, ana iya amfani da hanyoyin gwajin mannewa daban-daban, kamar gwajin tef, gwaji ko ja da gwaji.

Gwajin Solderability:

Gwajin solderability yana tabbatar da ikon maganin saman don sauƙaƙe aikin siyarwar. Wannan gwajin yana tabbatar da cewa PCB ɗin da aka sarrafa yana da ikon ƙirƙirar haɗin gwiwa mai ƙarfi da aminci tare da kayan lantarki. Hanyoyin gwaji na yau da kullun sun haɗa da gwajin solder mai iyo, gwajin ma'auni mai solder, ko gwajin auna ƙwallon solder.

Gwajin Dogara:

Gwajin dogaro yana kimanta aikin dogon lokaci da dorewar FPC Flex PCBs da aka yi masa magani a ƙarƙashin yanayi daban-daban. Wannan gwajin yana bawa masana'antun damar kimanta juriyar PCB ga hawan zafin jiki, zafi, lalata, damuwa na inji, da sauran abubuwan muhalli. Gaggawar gwajin rayuwa da gwaje-gwajen simintin muhalli, kamar hawan keke na zafi, gwajin feshin gishiri ko gwajin jijjiga, galibi ana amfani da su don tantance amincin.

Ta hanyar aiwatar da ingantacciyar kulawar inganci da hanyoyin gwaji, masana'antun za su iya tabbatar da cewa FPC Flex PCBs da ake bi da su a saman sun bi ka'idodin da ake buƙata da ƙayyadaddun bayanai. Waɗannan matakan suna taimakawa gano duk wani lahani ko rashin daidaituwa a farkon tsarin samarwa ta yadda za a iya ɗaukar ayyukan gyara cikin lokaci da haɓaka ingancin samfur gaba ɗaya da amincin.

6.Solving surface shirye-shiryen matsaloli a FPC m PCB masana'antu:

Matsalolin jiyya na saman na iya faruwa yayin aikin masana'anta, suna shafar ingancin gabaɗaya da aikin PCB mai sassauƙa na FPC. Wannan sashe zai gano batutuwan shirye-shiryen gama gari da kuma samar da shawarwarin magance matsala don shawo kan waɗannan ƙalubale yadda ya kamata.

Rashin mannewa mara kyau:

Idan ƙarewar bai bi daidai da abin da ake amfani da shi na PCB ba, yana iya haifar da delamination ko peeling. Wannan na iya zama saboda kasancewar gurɓatattun abubuwa, rashin isassun tarkace, ko rashin isasshen kunnawar saman. Don magance wannan, tabbatar da tsabtace saman PCB sosai don cire duk wani gurɓatawa ko saura kafin a yi amfani da su. Bugu da ƙari, haɓaka ƙaƙƙarfan yanayi da tabbatar da ingantattun dabarun kunna saman ƙasa, kamar maganin plasma ko kunna sinadarai, ana amfani da su don haɓaka mannewa.

Rufe mara daidaituwa ko kauri:

Rashin daidaituwar shafi ko kauri na platin zai iya zama sakamakon rashin isassun sarrafa tsari ko bambance-bambance a cikin roughness. Wannan matsalar tana shafar aiki da amincin PCB. Don shawo kan wannan matsala, kafa da kuma saka idanu matakan tsari masu dacewa kamar shafi ko lokacin plating, zafin jiki da maida hankali. Aiwatar da dabarun tashin hankali ko tashin hankali yayin sutura ko plating don tabbatar da rarraba iri ɗaya.

Oxidation:

PCBs da aka yi musu magani na iya yin oxidize saboda fallasa ga danshi, iska, ko wasu abubuwan da ke haifar da iskar oxygen. Oxidation na iya haifar da rashin ƙarfi na solderability da rage yawan aikin PCB. Don rage yawan iskar oxygen, yi amfani da jiyya mai dacewa kamar kayan shafa na halitta ko fina-finai masu kariya don samar da shinge ga danshi da abubuwan da ke haifar da iskar oxygen. Yi amfani da tsarin kulawa da kyau don rage fallasa iska da danshi.

Lalacewa:

Lalacewar saman PCB na iya yin mummunan tasiri ga mannewa da solderability na gamawar saman. Abubuwan gurɓata gama gari sun haɗa da ƙura, mai, sawun yatsa, ko saura daga hanyoyin da suka gabata. Don magance wannan, kafa ingantaccen shirin tsaftacewa don cire duk wani gurɓataccen abu kafin shiri na saman. Yi amfani da dabarun zubar da su da suka dace don rage yawan hulɗa da hannu ko wasu hanyoyin gurɓatawa.

Rashin Solderability:

Ana iya haifar da rashin iya solderability ta rashin kunnawa saman ko gurɓatawa a saman PCB. Rashin solderability mara kyau na iya haifar da lahani na walda da raunin haɗin gwiwa. Don inganta solderability, tabbatar da ingantattun dabarun kunnawa saman kamar su jiyya na jini ko kunna sinadarai ana amfani da su don haɓaka jika na saman PCB. Hakanan, aiwatar da ingantaccen shirin tsaftacewa don cire duk wani gurɓataccen abu wanda zai iya hana aikin walda.

7. Future ci gaban FPC sassauki jirgin masana'antu surface jiyya:

Filin kammalawa na FPC m PCBs yana ci gaba da haɓaka don saduwa da buƙatun fasahohi da aikace-aikace masu tasowa. Wannan sashe zai tattauna yuwuwar ci gaban gaba a cikin hanyoyin jiyya na sama kamar sabbin kayan, fasahar suturar ci gaba, da mafita masu dacewa da muhalli.

Wani yuwuwar haɓakawa a nan gaba na jiyya na saman FPC shine amfani da sabbin kayan aiki tare da ingantattun kaddarorin.Masu bincike suna binciko yadda ake amfani da suturar labari da kayan don haɓaka aiki da amincin FPCs masu sassauƙa na PCBs. Misali, ana yin bincike game da suturar warkar da kai, wanda zai iya gyara duk wani lalacewa ko ɓarna a saman PCB, ta haka yana ƙara tsawon rayuwarsa da dorewa. Bugu da ƙari, ana bincika kayan da ingantattun zafin zafin jiki don haɓaka ikon FPC don watsar da zafi don ingantacciyar aiki a aikace-aikacen zafin rana.

Wani ci gaba na gaba shine ci gaban fasahar suturar ci gaba.Ana haɓaka sabbin hanyoyin shafa don samar da ingantacciyar ɗaukar hoto iri ɗaya akan saman FPC. Dabaru irin su Atomic Layer Deposition (ALD) da Plasma Enhanced Chemical Vapor Deposition (PECVD) suna ba da damar mafi kyawun sarrafa kauri da abun da ke ciki, yana haifar da ingantaccen solderability da adhesion. Waɗannan fasahohin da suka ci-gaba suna da yuwuwar rage sauye-sauyen tsari da haɓaka haɓakar masana'anta gabaɗaya.

Bugu da kari, akwai ƙara girmamawa a kan muhalli m surface jiyya mafita.Tare da haɓaka ƙa'idodi da damuwa game da tasirin muhalli na hanyoyin shirye-shiryen ƙasa na gargajiya, masu bincike suna bincika mafi aminci, mafi ɗorewa madadin mafita. Misali, kayan kwalliyar ruwa suna samun karbuwa saboda ƙananan abubuwan da suke fitarwa (VOC). Bugu da kari, ana ci gaba da kokarin samar da hanyoyin da ba su dace da muhalli ba wadanda ba sa samar da kayayyaki masu guba ko sharar gida.

A takaice,Tsarin jiyya na saman yana taka muhimmiyar rawa wajen tabbatar da aminci da aiki na allon laushi na FPC. Ta hanyar fahimtar mahimmancin shirye-shiryen saman da zabar hanyar da ta dace, masana'antun za su iya samar da ingantattun da'irori masu sassauƙa waɗanda suka dace da bukatun masana'antu daban-daban. Aiwatar da tsarin jiyya na tsayayyen tsari, gudanar da gwaje-gwajen kula da inganci, da magance matsalolin jiyya yadda ya kamata zai ba da gudummawa ga nasara da tsawon rayuwar PCBs masu sassaucin ra'ayi na FPC a kasuwa.

Lokacin aikawa: Satumba-08-2023

Baya