A cikin wannan labarin, za mu dubi kayan da aka saba amfani da su a cikim buga kewaye masana'antu.

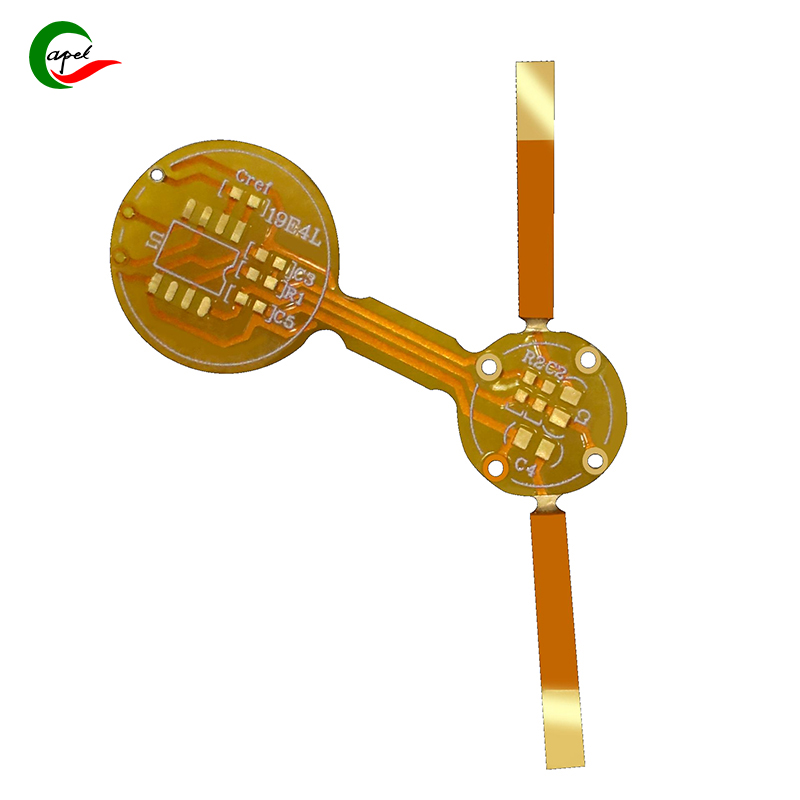

Wuraren da'irori masu sassauƙa (FPC) sun canza fanni na kayan lantarki da ban mamaki. Ƙarfinsu na lanƙwasa ya sa su shahara a masana'antu daban-daban da suka haɗa da sararin samaniya, motoci, kiwon lafiya, da na'urorin lantarki masu amfani.

Ɗaya daga cikin manyan kayan da aka yi amfani da su wajen samar da sassan da aka buga masu sassauƙa shine polyimide.Polyimide shine babban aikin polymer tare da kyakkyawan kwanciyar hankali na thermal, juriya na sinadarai da taurin inji. Waɗannan kaddarorin sun sa ya dace don sassauƙan da'irori kamar yadda zai iya jure yanayin zafi da matsananciyar yanayi ba tare da shafar aikin sa ba. Fina-finan da suka dogara da Polyimide galibi ana amfani da su azaman madaidaicin madauri masu sassauƙa.

Baya ga polyimide, wani abu da ake amfani da shi sau da yawa a masana'antar da'ira mai sassauƙa shine jan karfe.An zaɓi jan ƙarfe don kyakkyawan halayen wutar lantarki, juriya na lalata da ductility. Bakin tagulla na bakin ciki galibi ana makala shi zuwa madaidaicin polyimide don samar da hanyar da za'a bi. Layin jan ƙarfe yana ba da haɗin haɗin lantarki da ake buƙata don kewaya don aiki yadda ya kamata.

Don kare alamun tagulla kuma tabbatar da tsawon lokacin da'irar da aka buga, ana buƙatar murfin murfin ko abin rufe fuska.Overlay fim ne mai mannewa na thermoset da aka saba amfani da shi a saman da'ira. Yana aiki azaman mai kariya, yana kare alamun tagulla daga abubuwan muhalli kamar danshi, ƙura, da lalacewar jiki. Abubuwan rufewa yawanci fim ne na tushen polyimide, wanda ke da ƙarfin haɗin gwiwa kuma ana iya haɗa shi da ƙarfi ga ma'aunin polyimide.

Don ƙara haɓaka dorewa da aiki na madauri masu sassauƙa, ana amfani da kayan ƙarfafawa kamar tef ko kayan ƙarfafawa.Ƙara ƙarfafawa zuwa takamaiman wurare na kewaye inda ake buƙatar ƙarin ƙarfi ko taurin. Wadannan kayan zasu iya haɗawa da zaɓuɓɓuka iri-iri, irin su polyimide ko fim din polyester, fiberglass, ko ma karfen ƙarfe. Ƙarfafawa yana taimakawa hana da'irori daga yage ko karye yayin motsi ko aiki.

Bugu da ƙari, ana ƙara maɗaukaki ko lambobin sadarwa don sauƙaƙe haɗin kai tsakanin da'irar da'ira mai sassauƙa da sauran kayan aikin lantarki.An yi wa ɗ annan pad ɗin yawanci daga haɗe-haɗe na tagulla da kayan da ba za su iya jurewa ba. Pads ɗin haɗin gwiwa suna ba da madaidaicin ƙa'idar don siyarwa ko haɗin haɗin kai kamar haɗaɗɗun da'irori (ICs), resistors, capacitors, da masu haɗawa.

Bugu da ƙari ga ainihin kayan da ke sama, ana iya ƙara wasu abubuwa yayin aikin masana'antu dangane da takamaiman buƙatu.Misali, ana iya amfani da adhesives don haɗa yadudduka daban-daban na da'irori masu sassauƙa tare. Wadannan adhesives suna tabbatar da haɗin gwiwa mai ƙarfi kuma abin dogara, yana ba da damar da'irar don kiyaye amincin tsarin sa. Ana amfani da adhesives na silicone sau da yawa saboda sassaucin su, juriya mai zafi, da kyawawan abubuwan haɗin gwiwa.

Gabaɗaya, kayan aikin da aka yi amfani da su wajen samar da da'irori masu sassauƙa ana zaɓa su a hankali don tabbatar da ingantaccen aiki da dorewa.Haɗuwa da polyimide a matsayin ma'auni, jan ƙarfe don haɓakawa, overlays don kariya, kayan ƙarfafawa don ƙara ƙarfin ƙarfi, da pads don haɗin haɗin haɗin gwiwa yana haifar da abin dogara da cikakken aiki mai sassauƙa na bugawa. Ƙarfin waɗannan da'irori don daidaitawa da aikace-aikace iri-iri, gami da filaye masu lanƙwasa da matsatsun wurare, ya sa su zama makawa a cikin na'urorin lantarki na zamani.

A taƙaice, kayan da'ira masu sassauƙan bugu kamar su polyimide, jan karfe, overlays, ƙarfafawa, adhesives, da pads sune mahimman abubuwan haɗin gwiwa don ƙirƙirar da'irar lantarki masu ɗorewa da sassauƙa.Waɗannan kayan aikin suna aiki tare don samar da mahimman hanyoyin haɗin lantarki, kariya da ƙarfin injin da ake buƙata a cikin na'urorin lantarki na yau. Yayin da fasaha ke ci gaba da haɓakawa, kayan da ake amfani da su a cikin sassauƙan kera da'ira na iya haɓaka haɓakawa, da ba da damar ƙarin sabbin aikace-aikace.

Lokacin aikawa: Satumba-21-2023

Baya