Gabatarwa:

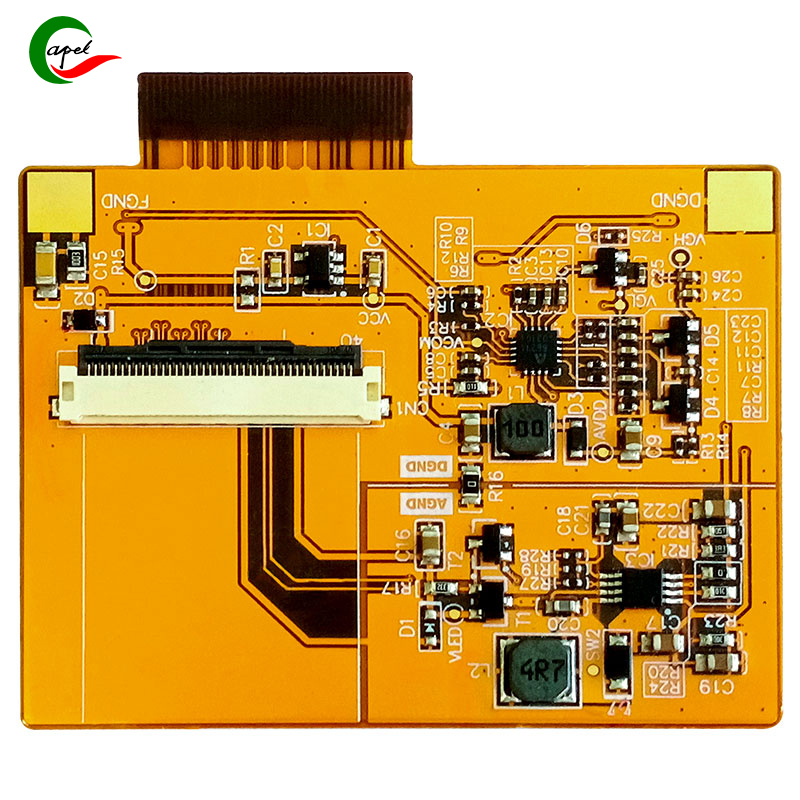

Samfurin PCB mai sassauƙa yana taka muhimmiyar rawa a masana'antar kera kayan lantarki. Yayin da fasaha ke ci gaba, buƙatar PCBs masu sassauƙa ya ƙaru sosai. A cikin wannan jagorar ƙarshe, za mu bincika sassauƙan ginin PCB, shimfidawa, da nau'ikan tari. Yana da mahimmanci a fahimci kalmomi masu zuwa:Manufacturing PCB mai sassauƙa, Tsarin PCB mai sassauƙa, Kauri PCB Copper Mai Sauƙi, Mashin PCB Solder Mask, Tsarin PCB mai sauƙi, M PCB Adhesive Sheet, da M PCB Layup Nau'in kamar yadda suke da mahimmanci don haɓaka samfuran ku.Yana da mahimmanci.

1. Basic ilmi na m PCB masana'antu:

A. Ma'anar ma'anar allo mai sassauƙa: PCB mai sassauƙa, wanda kuma aka sani da da'ira mai sassauƙa, allon kewayawa ne da aka buga wanda za a iya lanƙwasa, naɗewa, ko murɗawa ba tare da karyewa ba. Suna ba da fa'idodi da yawa akan PCBs masu tsauri, gami da sassauci, nauyi, da dorewa. Waɗannan kaddarorin sun sa su dace da aikace-aikace iri-iri, musamman waɗanda ke buƙatar ƙaramin lantarki da lanƙwasa.

B. Tsarin PCB mai sassauƙa: Tsarin gini na PCB mai sassauƙa ya haɗa da yin amfani da sassa masu sassauƙa. Abubuwan da aka fi amfani da su sune polyimide da polyester, waɗanda ke ba da mahimmancin sassauci da kaddarorin rufewa da ake buƙata don PCBs masu sassauƙa. Waɗannan ƴan ƙasa suna ɗaukar jerin matakan masana'anta kamar etching, plating, da lamination don ƙirƙirar ƙirar da'irar da ake so.

C. Fahimtar kaurin jan ƙarfe a cikin PCB mai sassauƙa: kauri na jan ƙarfe yana taka muhimmiyar rawa a cikin aikin PCB mai sassauƙa. Yana ƙayyade ƙarfin ɗaukar nauyi na yanzu, impedance, da sassauci na PCB. Za'a iya yin zaɓin kauri na jan ƙarfe daban-daban bisa ga ƙayyadaddun buƙatun ƙira. Tagulla mai kauri yana ba da ƙarfin ɗaukar nauyi na yanzu amma kuma yana rage sassaucin PCB. Dole ne a buga ma'auni mai kyau tsakanin waɗannan abubuwan don cimma kyakkyawan aiki.

2. Maɓalli na sassauƙa na masana'antar PCB mai sassauƙa:

A. Mashin solder PCB mai sassauƙa: Mashin solder Layer Layer ne mai kariya wanda ke rufe dandarar alamun tagulla akan PCB. Yana taimakawa hana gadoji mai siyarwa, lalata, da gajeren wando na lantarki yayin walda. PCB mai sassauƙa yana amfani da kayan rufe fuska na musamman don tabbatar da sassauci da karko. Zaɓin abin rufe fuska na PCB mai sassauƙa da tsarin aikace-aikacen yana buƙatar yin la'akari da ƙirar PCB da aikace-aikacen da aka yi niyya.

B. M PCB Layout: Kyakkyawan tsarawa, shimfidar PCB mai sassauƙa yana da mahimmanci don ingantaccen aiki da aminci. Ya ƙunshi jeri na abubuwan da aka gyara, kewayawa da ganowa, da la'akari da amincin sigina. Dole ne a sanya abubuwan da aka gyara ta hanyar da za ta ba PCB damar tanƙwara da lanƙwasa daidai. Yakamata a bi diddigin sawu don rage damuwa a wuraren sassauƙa da tabbatar da ingantaccen watsa sigina. Mafi kyawun ayyuka don zayyana shimfidar PCB mai sassauƙa sun haɗa da yin amfani da laƙabi mai lankwasa, guje wa kusurwoyi masu kaifi, da tabbatar da isassun sharewa tsakanin sawu.

C. M PCB m takardar: Ana amfani da takardar m a cikin m PCB masana'antu to bond daban-daban yadudduka tare. Yana ba da ƙarfin injina, kwanciyar hankali, da rufi. Akwai nau'ikan zanen gado na manne daban-daban, kamar su zanen gadon acrylic, zanen gadon epoxy, da zanen gadon roba. Zaɓin takardar manne ya dogara da dalilai kamar juriya na zafin jiki, buƙatun sassauci, da dacewa da wasu kayan. Zaɓin madaidaicin takardar manne yana da matukar mahimmanci don tabbatar da aminci da dorewa na PCB ɗin ku mai sassauƙa.

3. Nau'in tari na PCB masu sassauƙa:

A. Gabatarwa zuwa PCB stackup: PCB stackup yana nufin tsari na yadudduka daban-daban a cikin PCB. A cikin masana'antar PCB mai sassauƙa, tari yana taka muhimmiyar rawa a cikin amincin sigina, sarrafa impedance, da kula da thermal. Ta hanyar zaɓe a hankali da tsara yadudduka, masu ƙira za su iya haɓaka aikin PCB masu sassauƙa.

B. Nau'in Layukan PCB Mai Sauƙi na gama gari: Akwai nau'ikan layup iri-iri da ake amfani da su a cikin masana'antar PCB masu sassauƙa, gami da saiti ɗaya, Layer-Layer, da saiti masu yawa. Kowane nau'in tari yana da fa'ida da gazawarsa. PCBs masu sassaucin ra'ayi guda ɗaya sune mafi sauƙi kuma mafi tsadar zaɓi, amma suna da iyakataccen damar sarrafa hanya. PCB mai sassauƙan Layer Layer yana ba da ƙarin zaɓuɓɓukan wayoyi kuma yana iya ɗaukar ƙarin ƙira. Multilayer m PCBs suna ba da mafi girman sassaucin ra'ayi, da ingantacciyar kulawar impedance, kuma suna iya tallafawa mafi girman girman kewaye. Koyaya, sun fi rikitarwa da tsada don kera.

A takaice:

A cikin wannan cikakkiyar jagorar, mun rufe dukkan fannoni na masana'antar PCB mai sassauƙa, gami da gini, shimfidawa, abin rufe fuska, zanen gado, da nau'ikan tari. Fahimtar waɗannan mahimman abubuwan zai ba masu ƙira damar haɓaka aiki da amincin ƙirar PCB ɗin su masu sassauƙa. Tsari da fasaha suna da mahimmanci ga samar da PCB masu sassauƙa, kuma ta bin mafi kyawun ayyuka, masana'antun za su iya tabbatar da isar da ingantattun samfuran inganci, abin dogaro don biyan bukatun masana'antar lantarki.

Lokacin aikawa: Nuwamba-10-2023

Baya