Abubuwan da aka haɗa ta ramuka, kamar yadda sunan ke nunawa, suna da jagora ko fil waɗanda aka saka ta cikin rami a cikin PCB kuma ana sayar da su zuwa kushin a wancan gefen. Ana amfani da waɗannan abubuwan da yawa a cikin masana'antu saboda amincin su da sauƙin gyarawa. Don haka, ko PCBs masu tsauri za su iya ɗaukar abubuwan haɗin ramuka? Mu zurfafa zurfafa cikin wannan maudu’in domin ganowa.Koyaya, tambaya gama gari da ta taso yayin la'akari da amfani da PCBs masu ƙarfi shine dacewarsu da abubuwan ramuka.

A takaice, amsar ita ce eh, PCBs masu sassaucin ra'ayi sun dace da abubuwan haɗin ramuka. Koyaya, ana buƙatar la'akari da wasu la'akari da ƙira don tabbatar da haɗin kai mai nasara.

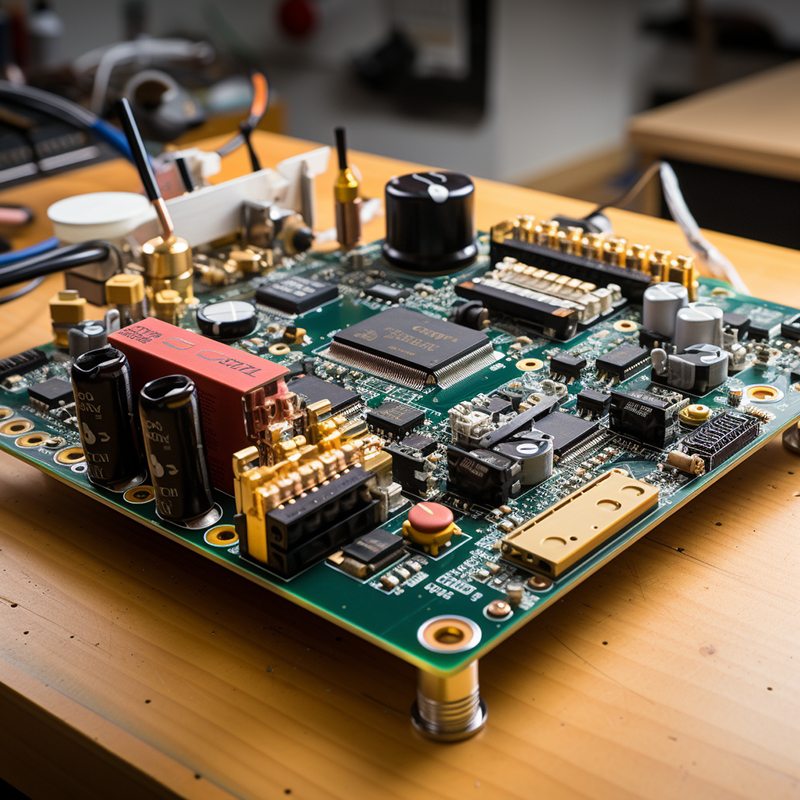

A cikin yanayin fasahar haɓaka cikin sauri na yau, buƙatar na'urorin lantarki waɗanda ke ba da babban aiki a cikin ƙananan sifofi ya zama al'ada. Saboda haka, ana tilasta masana'antar da'ira ta Buga (PCB) don ƙirƙira da haɓaka sabbin hanyoyin magance waɗannan buƙatu. Magani ɗaya shine gabatarwar PCBs masu sassaucin ra'ayi, waɗanda ke haɗa sassaucin PCBs masu sassauƙa tare da ƙarfi da karko na PCBs masu ƙarfi.

PCBs masu tsattsauran ra'ayi sun shahara tare da masu zanen kaya da masana'antun don iyawarsu na haɓaka sassaucin ƙira yayin rage girman gabaɗaya da nauyi.Ana amfani da su a cikin aikace-aikace iri-iri, gami da sararin samaniya, na'urar likitanci, na'urorin lantarki da masana'antar kera motoci.

Ɗaya daga cikin manyan abubuwan da ke damun lokacin amfani da abubuwan ramuka a kan PCBs masu sassaucin ra'ayi shine damuwa na inji wanda za'a iya amfani da shi ga mahaɗin solder yayin haɗuwa ko amfani a cikin filin. PCB mai ƙarfi, kamar yadda sunan ke nunawa, ya ƙunshi wurare masu tsauri da sassauƙa waɗanda aka haɗa su ta hanyar ramuka ko masu haɗawa masu sassauƙa.Sassan sassa masu sassauƙa suna da 'yanci don tanƙwara ko karkatar da PCB, yayin da ƙananan sassa ke ba da kwanciyar hankali da goyan baya ga taron. Don ɗaukar abubuwan da ke cikin ramuka, masu zanen kaya suna buƙatar zaɓar wurin ramukan a hankali kuma su tabbatar an sanya su a wani yanki mai tsauri na PCB don guje wa damuwa mai yawa akan mahaɗan saida.

Wani muhimmin abin la'akari shine amfani da madaidaitan wuraren anka don abubuwan haɗin ramuka. Domin PCBs masu sassaucin ra'ayi na iya lanƙwasa ko murɗawa, yana da mahimmanci don samar da ƙarin tallafi don hana wuce gona da iri da damuwa akan mahaɗin solder.Ana iya samun ƙarfafawa ta hanyar ƙara stiffeners ko shinge a kusa da ɓangaren ramin don rarraba damuwa daidai.

Bugu da ƙari, masu zanen kaya ya kamata su kula da girman da daidaitawar abubuwan haɗin ramuka. Ya kamata a yi girman ramuka yadda ya kamata don tabbatar da dacewa, kuma abubuwan da aka gyara yakamata a daidaita su don rage haɗarin kutse tare da abubuwan sassauƙa na PCB.

Har ila yau, yana da daraja ambaton cewa ci gaban fasahar kere-kere na PCB ya ba da damar samar da PCB masu tsauri ta amfani da fasahar haɗin kai mai girma (HDI).HDI yana ba da damar ƙaramar sassa da ƙara yawan da'ira, yana sauƙaƙa ɗaukar abubuwan haɗin ramuka akan sashin sassauƙa na PCB ba tare da lalata aiki ko dogaro ba.

A takaice, PCBs masu sassaucin ra'ayi na iya zama masu dacewa da abubuwan ramuka idan an yi la'akari da wasu abubuwan ƙira.Ta hanyar zaɓar wurare a hankali, samar da isasshen tallafi, da cin gajiyar ci gaba a cikin fasahar kere kere, masu zanen kaya na iya samun nasarar haɗa abubuwan haɗin ramuka cikin PCB masu ƙarfi ba tare da lalata aiki ko dogaro ba. Yayin da fasaha ke ci gaba da ci gaba, amfani da PCBs masu tsauri kawai ana tsammanin haɓakawa, yana ba da ƙarin dama don ingantacciyar ƙira ta lantarki.

Lokacin aikawa: Satumba-20-2023

Baya