Buga allon kewayawa (PCBs) abu ne mai mahimmanci yayin ƙira da kera kayan lantarki. PCB wani muhimmin sashi ne na yawancin na'urorin lantarki, yana samar da dandamali don haɗa abubuwan lantarki daban-daban. A cikin 'yan shekarun nan, an sami karuwar buƙatun PCB masu sassauƙa saboda iyawarsu ta jure hadaddun aikace-aikace masu ƙarfi. Rigid Flex Circuit Board hade ne na PCB mai tsauri da sassauƙa, wanda ke da fa'idodi na musamman a cikin ceton sararin samaniya, karko da dogaro. Koyaya, babban abin damuwa tsakanin masana'antun da masu siye shine ko waɗannan sabbin Rigid Flex Pcb zasu fi tsada idan aka kwatanta da tsayayyen PCBs na gargajiya. Anan za mu bincika abubuwan tsadar da ke da alaƙa da PCBs masu ƙarfi da ƙayyadaddun yuwuwar su idan aka kwatanta da allunan kewayawa na gargajiya.

Koyi game da rigid-flex alluna:

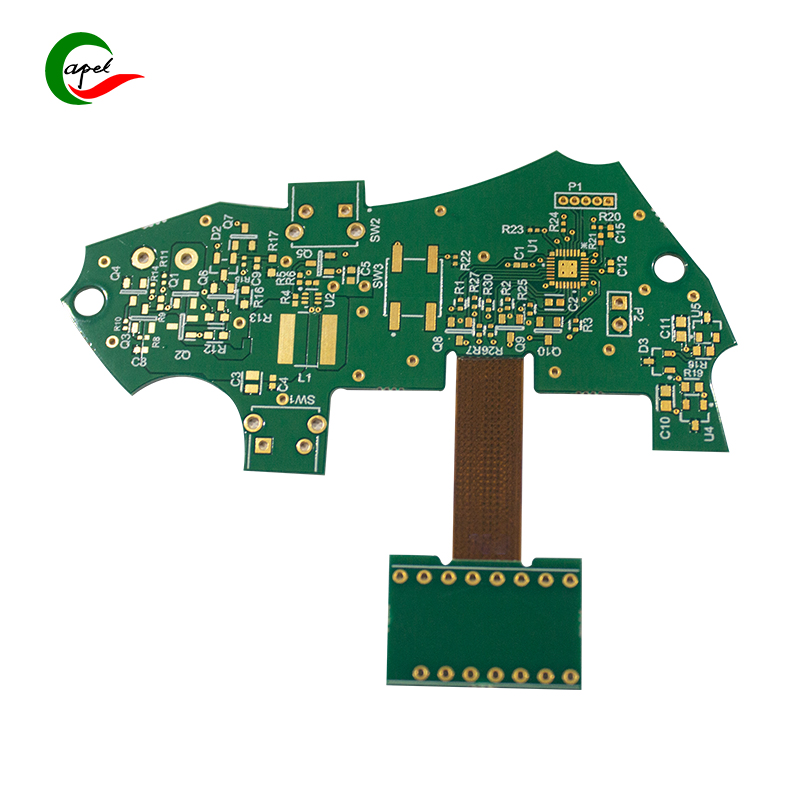

Rigid Flex Circuits haɗe ne na PCBs masu ƙarfi da sassauƙa, suna ba da mafi kyawun duniyoyin biyu. Sun ƙunshi yadudduka masu sassauƙa da yawa waɗanda ke haɗa haɗin kai ta sassa masu tsauri. Wannan zane yana ba da damar da'irar da aka buga don lanƙwasa da sassauƙa yayin tabbatar da daidaiton tsari da ƙarfi.

Abubuwan da ke shafar farashin Al'amuran da'ira na PCB:

Abubuwan da ke shafar farashin Allolin da'ira na Buga na iya bambanta dangane da takamaiman buƙatun aikin. Ga wasu abubuwan gama gari don

la'akari:

Rukunin ƙira:Allolin da'ira na Lantarki tare da rikitattun shimfidu na kewayawa, manyan abubuwan daɗaɗɗa, da sarƙaƙƙiyar tsarin wayoyi suna buƙatar ƙarin dabarun masana'anta kuma yana iya haɗawa da farashi mai girma.

Adadin yadudduka:Da'irar da aka buga na iya zama mai gefe ɗaya, mai gefe biyu ko mai nau'i-nau'i. Ƙarin yadudduka suna ba da izini don ƙarin ƙira masu rikitarwa, amma kuma suna haɓaka farashin masana'anta gaba ɗaya.

Yawan:Yawan da'ira da ake buƙata don aiki zai shafi farashin. Yawan girma yawanci yana haifar da tattalin arziƙin sikeli da ƙananan farashi.

Abubuwan Amfani:Zaɓin kayan hukumar da'ira Buga na PCB yana shafar farashi. Abubuwan da suka fi tsada, irin su manyan laminates ko kayan da ke da kaddarorin musamman, na iya ƙara yawan farashi.

Ƙarshen saman:Ƙarshen da ake so, irin su HASL (Hot Air Solder Leveling), ENIG (Electroless Nickel Immersion Gold), ko OSP (Organic Solderability Preservative), yana rinjayar farashi.Wasu jiyya na saman suna buƙatar ƙarin matakan sarrafawa, ƙarawa ga yawan farashi.

Hadarin hakowa da niƙa:Kwamfutar PCb tare da rikitattun tsarin hakowa ko hadaddun buƙatun niƙa suna ƙara lokaci da farashi.

Bukatun Musamman:Wasu dalilai kamar sarrafa impedance, buƙatun tarawa na musamman, makafi/binne vias ko hakowa zurfin sarrafawa na iya shafar farashi yayin da suke buƙatar ƙarin dabarun masana'antu.

Zaɓaɓɓen Mai ƙira:Masana'antun daban-daban suna da tsarin farashi daban-daban, iyawa, da ƙimar inganci. Zaɓin masana'anta mai suna na iya shafar farashi da inganci

Tsarin sarrafawa:Tsarin masana'anta na allunan gyare-gyare masu ƙarfi sun haɗa da sassauƙa da sassauƙa. Wannan na iya buƙatar kayan aiki na musamman da dabaru, waɗanda ke ƙara ƙimar gabaɗaya.

Gwaji da Kula da Inganci:Gwaji mai tsauri da matakan sarrafa inganci suna da mahimmanci don tabbatar da aminci da aiki na alluna masu sassauƙa.

Kwamitin tsattsauran ra'ayi da Kwamitin PCB na gargajiya: kwatankwacin farashi:

Domin sanin ko tsayayyen allo sun fi tsada fiye da PCBs na gargajiya, muna buƙatar bincika farashi daban-daban.

dalilai:

a) Rukunin ƙira:Al'amuran PCB masu tsattsauran ra'ayi suna ba da damar ƙira masu rikitarwa tare da sifofi masu rikitarwa da daidaitawar 3D. Duk da yake irin waɗannan ƙira na iya ƙara ƙira na farko da farashin saiti, ba sa buƙatar ƙarin masu haɗawa da wayoyi, rage lokacin taro da farashi.

b) Farashin kayan:Allolin da'ira bugu masu tsauri sau da yawa suna buƙatar kayan musamman waɗanda zasu iya jure lankwasa da lanƙwasa. Duk da yake waɗannan kayan na iya zama ɗan tsada fiye da kayan da'ira bugu na gargajiya, idan aka yi la'akari da karuwar samuwa da buƙatar irin waɗannan kayan, bambancin farashin gabaɗaya yawanci ƙanana ne.

c) Tsarin sarrafawa:Tsarin kera na PCBs masu tsauri sun haɗa da haɗaɗɗun sassauƙa da da'ira, waɗanda na iya buƙatar fasaha na musamman da kayan aiki. Duk da yake wannan yana ƙara daɗaɗar tsarin masana'anta, ci gaban fasaha ya sanya waɗannan hanyoyin samun sauƙi kuma masu tsada.

d) ajiye sarari:Kwamitin da'ira na PCB mai tsauri yana kawar da buƙatun masu haɗawa da wayoyi, yana ba da damar ƙarin ƙirar ƙira. Rage girman yana adana farashi a cikin amfani da kayan gabaɗaya da lokacin haɗuwa.

e) Amincewa da Dorewa:Alƙalai masu tsattsauran ra'ayi na iya jure lankwasawa, jujjuyawa, da rawar jiki don ƙara ƙarfi. Wannan haɓakar aminci yana haifar da tanadin farashi ta hanyar rage kulawa da farashin maye gurbin duk rayuwar kayan aiki.

f) Farashin dogon lokaci:Yayin da farashin farko na rigid-flex na iya zama mafi girma, farashi na dogon lokaci na iya zama ƙasa da ƙasa saboda ƙaƙƙarfan aminci da dorewa. PCBs na al'ada na iya buƙatar ƙarin kulawa akai-akai, gyare-gyare da sauyawa, yana haifar da ƙarin farashi akan lokaci.

g) takamaiman fa'idodi:Wuraren da'irori masu tsattsauran ra'ayi suna ba da fa'idodi masu mahimmanci a wasu aikace-aikace, kamar su wearables, sararin samaniya, da na'urorin lantarki na mota. Adadin da aka samu daga amfani da PCBs masu tsauri a cikin waɗannan ƙa'idodi na musamman na iya fin ƙimar farko mafi girma.

h) Ƙarfafawa:pcbs masu sassaucin ra'ayi na iya ba da fa'idodin daidaitawa, musamman don ƙira waɗanda ke buƙatar faɗaɗa ko haɓakawa na gaba. Waɗannan allunan na iya ɗaukar ƙarin abubuwan da aka gyara ko ayyuka ba tare da ɗimbin sake yin aiki ko sake tsarawa ba, adana farashi mai alaƙa da sake tsarawa da sake yin aiki.

i) Gabaɗaya hadaddun aikin:Hakanan kwatankwacin farashi ya dogara ne akan ƙayyadaddun aikin gaba ɗaya. Idan aikin yana buƙatar alluna da yawa, hadaddun haɗin haɗin gwiwa, ko takamaiman nau'i nau'i, PCBs masu sassauƙa na iya samar da mafita mai inganci mai tsada ta hanyar rage hadaddun taro da sauƙaƙe ƙira gabaɗaya.

j) Farashin samfur:Prototyping wani muhimmin mataki ne a masana'antar PCB wanda ke shafar farashin gabaɗaya. Duk da yake samfuran PCB masu tsauri na iya zama masu tsada da farko, za su iya samar da ingantaccen wakilci na samfurin ƙarshe, mai yuwuwar rage farashin da ke da alaƙa da ƙira da gyare-gyare.

Nazarin Harka:

Hali na 1:

Muna amfani da ƙera wayoyi a matsayin misali. A al'adance, an yi amfani da allunan pcb masu tsauri don kewaya wayoyin hannu. Koyaya, tare da buƙatun ƙira masu ƙayatarwa da ƙaƙƙarfan ƙira, ƙayyadaddun allon kewayawa sun zama mafi shahara.

Da farko, masana'antun sun yi jinkirin canzawa zuwa m-sauƙaƙƙiya saboda damuwar farashi. Koyaya, bayan ƙarin kimantawa, sun gane cewa fa'idodin sun zarce yuwuwar bambancin farashi. Wuraren da'irori na PCB masu sassauƙa suna yin ingantaccen amfani da sararin samaniya saboda ana iya siffa su don dacewa da yanayin yanayin wayar hannu. Wannan yana kawar da buƙatar ƙarin masu haɗawa da igiyoyi, rage lokacin taro da farashi. Bugu da kari, PCB mai tsauri yana kara karko. Wayoyin hannu sukan lanƙwasa da lanƙwasa yayin amfani da yau da kullun. An tsara da'irori masu tsauri da aka buga don jure wa waɗannan matsalolin, rage yuwuwar lalacewar da'ira. Wannan kuma yana rage buƙatar gyare-gyare da sauyawa, yana haifar da ajiyar kuɗi na dogon lokaci. Ƙara yawan buƙatun wayoyin hannu da na'urori masu sawa ta amfani da PCBs masu sassaucin ra'ayi kuma ya haifar da haɓaka gasa tsakanin masana'antun PCB. A sakamakon haka, farashin m-flex ya zama mafi m, yana mai da shi wani zaɓi na tattalin arziki ga masana'antun.

Hali na 2:

A cikin masana'antar na'urorin likitanci, ana ƙara amfani da PCB masu ƙarfi a cikin na'urori kamar na'urorin bugun zuciya da na'urorin ji. Saboda mahimmancin yanayin ayyukansu, waɗannan na'urori suna buƙatar ƙirar ƙira da manyan matakan dogaro. Masu kera bugun zuciya misali ne na fa'idodin tsadar amfani da da'irori masu ƙarfi a cikin na'urorin likita. A al'adance, na'urorin bugun zuciya suna amfani da tsayayyen allunan kewayawa, waɗanda ke iyakance girma da siffar na'urar. Koyaya, ta hanyar amfani da fasahar PCB mai tsauri, masana'antun zasu iya shawo kan waɗannan iyakoki. Amfani da PCB mai sassauƙa mai tsauri yana ba da damar ƙirar ƙirar bugun zuciya, rage girma da nauyin na'urar. Wannan ba kawai inganta ta'aziyya na haƙuri ba, amma har ma yana rage yawan masana'antu da farashin kayan aiki. Ƙananan girman kayan aiki yana nufin ƙarancin albarkatun da ake buƙata don samarwa, adana farashi.

Wata fa'ida ta yin amfani da tsayayyen sassauƙa a cikin na'urorin likitanci shine ƙara dogaro. An ƙera alluna masu ƙarfi-madaidaicin don jure yanayin aiki mai tsauri kamar canjin zafin jiki, girgiza, da danshi. Sau da yawa waɗannan yanayi a cikin jiki suna shafar na'urorin bugun zuciya da na'urorin ji. Ta amfani da allunan da'ira bugu mai ƙarfi, masana'antun za su iya tabbatar da dogaro na dogon lokaci da aikin waɗannan na'urori. Wannan yana rage buƙatar kulawa akai-akai ko sauyawa, adana kuɗi akan lokaci.

Bugu da kari, ikon siffanta siffa da nau'in PCB don biyan bukatun na'urar wani bangare ne na ceton farashi. Misali, game da na'urorin ji, ana iya siffata PCB mai sassauƙa mai tsauri don dacewa da lanƙwan kunne, yana haifar da ƙira mai daɗi da hankali. Wannan gyare-gyare yana kawar da buƙatar ƙarin abubuwan haɗin gwiwa da masu haɗawa, rage lokacin taro da farashi.

Hali na 3:

A cikin sararin samaniya da masana'antu na kera motoci, amfani da PCBs masu tsauri ya tabbatar da zama zaɓi mai tsadar gaske saboda iyawarsu don biyan buƙatun waɗannan masana'antu. Bari mu kalli wani bincike daga masana'antar sararin samaniya don fahimtar fa'idodin farashi.

Aerospace A cikin masana'antar sararin samaniya, dogaro da dorewa sune mahimmanci. Aikace-aikacen sararin samaniya sau da yawa sun haɗa da matsananciyar canje-canjen zafin jiki, manyan matakan girgiza, da ci gaba da bayyana danshi. Sabili da haka, don tabbatar da aikin da ake buƙata da aminci, amfani da PCBs masu tsauri ya zama gama gari.

A cikin binciken da wani babban kamfani na sararin samaniya ya gudanar, an kwatanta amfani da PCBs masu ƙarfi a cikin ƙirar tsarin sadarwar tauraron dan adam da amfani da PCBs na gargajiya. Tsarin sadarwar tauraron dan adam yana buƙatar ƙaƙƙarfan ƙira masu nauyi don a harba su zuwa sararin samaniya. Ta hanyar aiwatar da ƙirar PCB mai tsauri, kamfanin ya sami damar samun babban tanadin nauyi idan aka kwatanta da ingantaccen ƙirar PCB na gargajiya. Wannan raguwar nauyi yana haifar da raguwar farashin harbawa saboda ƙarancin man da ake buƙata don tura tauraron dan adam zuwa sararin samaniya.

Bugu da kari, PCBs masu sassaucin ra'ayi sun fi karami kuma suna amfani da sarari yadda ya kamata, suna ba da damar haɗa ƙarin fasali da ayyuka cikin tsarin sadarwa. Bugu da ƙari, ƙaƙƙarfan ƙarfi da sassauƙa na PCBs masu sassaucin ra'ayi suna ba da ingantacciyar karko da dogaro. PCBs suna iya jure yanayin yanayin sararin samaniya, gami da yanayin zafi da girgiza yayin ƙaddamarwa da aiki, rage yuwuwar gazawar da buƙatar gyara ko sauyawa. Wannan bi da bi yana adana kuɗi ta fuskar kulawa da lokacin raguwa.

Bugu da ƙari, fa'idodin tsadar amfani da PCBs masu ƙarfi a cikin aikace-aikacen sararin samaniya sun wuce matakin masana'anta. Ƙirƙirar tsarin tsarin da rage nauyi yana sa shigarwa, kiyayewa da gyaran hanyoyin sauƙi. Wannan kuma yana rage farashin aiki da kuma lokacin da ake buƙata don waɗannan ayyukan, yana haifar da ajiyar kuɗi gaba ɗaya.

Dangane da binciken da aka yi a sama, ana iya cewa:

Allolin da'ira masu tsattsauran ra'ayi suna ba da fa'idodi iri-iri, gami da tanadin sararin samaniya, ƙarin aminci, da ingantacciyar dorewa. Yayin da hasashe na farko na iya zama cewa PCBs masu tsauri sun fi tsada, kwatancen farashi ya nuna cewa bambancin farashin sau da yawa ƙanana ne kuma har ma yana da tsada yayin la'akari da fa'idodin gabaɗayan. Kamar yadda fasaha ke ci gaba da haɓaka buƙatu, ratawar farashi tsakanin PCBs na gargajiya da allunan sassauƙa na ci gaba da raguwa. Sabili da haka, saka hannun jari a cikin PCBs masu sassaucin ra'ayi na iya zama zaɓi mai hikima, tabbatar da ƙarin ƙaƙƙarfan mafita, abin dogaro da dorewa don kayan lantarki na zamani.Shenzhen Capel Technology Co., Ltd. ya kafa masana'anta mai ƙarfi Flex Pcb a cikin 2009 kuma ƙwararre ce ta Flex Rigid Pcb Manufacturer. Tare da shekaru 15 na ƙwarewar aikin ƙwararru, kwararar tsari mai ƙarfi, ƙwarewar fasaha, ingantaccen kayan aikin sarrafa kansa, ingantaccen tsarin kula da inganci, kuma Capel yana da ƙwararrun ƙwararrun ƙwararrun ƙwararrun ƙwararrun ƙwararrun ƙwararrun ƙwararrun ƙwararrun ƙwararrun ƙwararrun ƙwararrun ƙwararrun ƙwararrun ƙwararrun ƙwararrun ƙwararrun ƙwararrun ƙwararrun ƙwararrun ƙwararrun ƙwararrun don samarwa abokan cinikin duniya madaidaici, inganci mai ƙarfi Flex Rigid Pcb, Rigid. Flex Pcb Fabrication, Saurin Juya Rigid Flex Pcb,.Maganin tallace-tallacen mu na farko da sabis na fasaha na tallace-tallace da isar da lokaci ya ba abokan cinikinmu damar yin amfani da damar kasuwa da sauri don ayyukan su.

Lokacin aikawa: Agusta-25-2023

Baya