Samfurin Samfurin Pcb Manufacturer Allolin Kewaye Mai Sided Biyu

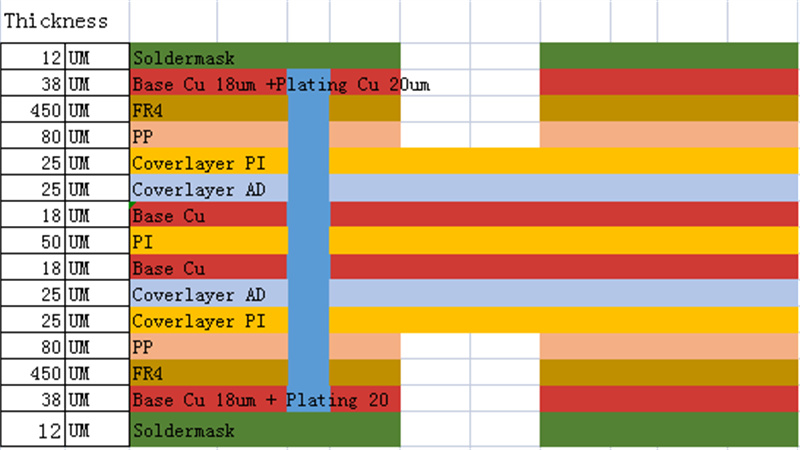

Ƙarfin Tsari na PCB

| A'a. | Aikin | Manuniya na fasaha |

| 1 | Layer | 1-60 (Layer) |

| 2 | Matsakaicin wurin sarrafawa | 545 x 622 mm |

| 3 | Mafi qarancin kauri | 4 (Layer) 0.40mm |

| 6 (Layer) 0.60mm | ||

| 8 (Layer) 0.8mm | ||

| 10 (Layer) 1.0mm | ||

| 4 | Mafi ƙarancin faɗin layi | 0.0762 mm |

| 5 | Mafi ƙarancin tazara | 0.0762 mm |

| 6 | Mafi ƙarancin buɗaɗɗen inji | 0.15mm |

| 7 | Ramin bangon jan karfe | 0.015 mm |

| 8 | Jurewar buɗaɗɗen ƙarfe | ± 0.05mm |

| 9 | Haƙurin buɗaɗɗen ƙarfe mara ƙarfe | ± 0.025mm |

| 10 | Haƙuri ramuka | ± 0.05mm |

| 11 | Haƙuri na girma | ± 0.076mm |

| 12 | Mafi ƙarancin gada mai siyarwa | 0.08mm |

| 13 | Juriya na rufi | 1E+12Ω (na al'ada) |

| 14 | rabon kauri na faranti | 1:10 |

| 15 | Thermal girgiza | 288 ℃ (sau 4 a cikin dakika 10) |

| 16 | Karkatawa da lankwasa | ≤0.7% |

| 17 | Ƙarfin wutar lantarki | 1.3KV/mm |

| 18 | Ƙarfin cirewa | 1.4N/mm |

| 19 | Solder tsayayya taurin | ≥6H |

| 20 | Dagewar harshen wuta | 94V-0 |

| 21 | Sarrafa impedance | ± 5% |

Muna yin Prototyping Boards tare da ƙwarewar shekaru 15 tare da ƙwarewar mu

4 Layer Flex-Rigid Boards

8 Layer Rigid-Flex PCBs

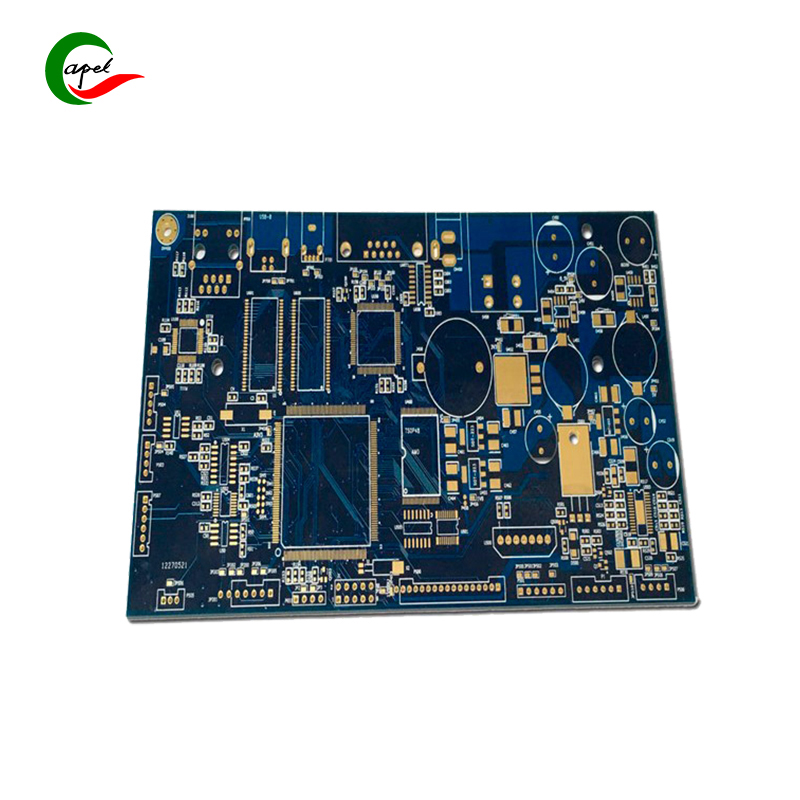

8 Layer HDI Buga Allolin da'ira

Gwaji da Kayan Aiki

Gwajin Microscope

Binciken AOI

Gwajin 2D

Gwajin Tashin hankali

Gwajin RoHS

Binciken Flying

Gwaji na kwance

Lankwasawa Teste

Sabis ɗin Samfurin Samfurin Sabis ɗinmu

. Bayar da goyon bayan fasaha Pre-tallace-tallace da bayan-tallace-tallace;

. Custom har zuwa 40 yadudduka, 1-2days Saurin jujjuya abin dogaro da samfur, Sayen kayan aikin, Majalisar SMT;

. Yana ba da na'urar lafiya duka, Kula da Masana'antu, Motoci, Jirgin Sama, Lantarki na Mabukaci, IOT, UAV, Sadarwa da sauransu.

. Ƙungiyoyin injiniyoyinmu da masu bincike sun sadaukar da kai don cika bukatunku tare da daidaito da ƙwarewa.

Yadda ake kera kwamitocin da'ira mai gefe biyu masu inganci?

1. Zana allo: Yi amfani da software na taimakon kwamfuta (CAD) don ƙirƙirar shimfidar allo. Tabbatar cewa ƙira ta cika duk buƙatun lantarki da na inji, gami da faɗin alama, tazara, da jeri na sassa. Yi la'akari da abubuwa kamar amincin sigina, rarraba wutar lantarki, da sarrafa zafi.

2. Samfura da gwaji: Kafin samarwa da yawa, yana da mahimmanci don ƙirƙirar allon samfur don tabbatar da ƙira da ƙirar ƙira. Gwajin samfura sosai don aiki, aikin lantarki, da dacewa da injina don gano duk wata matsala ko haɓakawa.

3. Zaɓin Material: Zaɓi wani abu mai inganci wanda ya dace da ƙayyadaddun bukatun hukumar ku. Zaɓuɓɓukan kayan gama-gari sun haɗa da FR-4 ko FR-4 mai zafi mai zafi don ma'auni, jan ƙarfe don alamomi, da abin rufe fuska don kare abubuwan da aka gyara.

4. Kera Layer na ciki: Da farko shirya Layer na ciki na allo, wanda ya ƙunshi matakai da yawa:

a. Tsaftace kuma a daidaita laminate ɗin jan ƙarfe.

b. Aiwatar da busasshen fim na bakin ciki mai ɗaukar hoto zuwa saman jan karfe.

c. Fim ɗin yana fuskantar hasken ultraviolet (UV) ta hanyar kayan aikin hoto mai ɗauke da tsarin da'ira da ake so.

d. An haɓaka fim ɗin don cire wuraren da ba a bayyana ba, barin tsarin kewayawa.

e. Etch fallasa jan karfe don cire abubuwan da suka wuce gona da iri wanda ya bar burbushi da mashinan da ake so kawai.

F. Bincika Layer na ciki don kowane lahani ko sabawa daga ƙira.

5. Laminates: Ciki yadudduka suna haɗuwa tare da prepreg a cikin latsawa. Ana amfani da zafi da matsa lamba don haɗa yadudduka da kuma samar da kwamiti mai ƙarfi. Tabbatar cewa yadudduka na ciki sun daidaita daidai kuma an yi rajista don hana kowane rashin daidaituwa.

6. Hakowa: Yi amfani da ingantacciyar injin hakowa don haƙa ramuka don hawan sassa da haɗin kai. Ana amfani da nau'i-nau'i daban-daban na raƙuman ruwa bisa ga takamaiman buƙatu. Tabbatar da daidaiton wurin rami da diamita.

Yadda ake kera kwamitocin da'ira mai gefe biyu masu inganci?

7. Lantarki maras amfani da Copper Plating: Aiwatar da bakin ciki Layer na jan karfe zuwa duk fallasa na ciki saman. Wannan matakin yana tabbatar da ingantaccen aiki mai dacewa kuma yana sauƙaƙe tsarin plating a cikin matakai na gaba.

8. Hoto na waje: Kama da tsarin tsarin ciki, an rufe fim ɗin busasshen hoto mai ɗaukar hoto akan Layer na jan karfe na waje.

Bayyana shi zuwa hasken UV ta hanyar kayan aikin hoto na sama kuma haɓaka fim ɗin don bayyana tsarin kewayawa.

9. Etching na waje: Fitar da jan ƙarfe mara amfani a saman Layer na waje, yana barin alamun da ake buƙata.

Bincika Layer na waje don kowane lahani ko sabawa.

10. Solder Mask da Legend Printing: Aiwatar da solder abin rufe fuska don kare tagulla burbushi da gammaye yayin barin yankin domin bangaren hawa. Buga tatsuniyoyi da alamomi a saman saman da ƙasa yadudduka don nuna wurin wuri, polarity, da sauran bayanai.

11. Shirye-shiryen Surface: Ana amfani da shirye-shiryen saman don kare saman jan ƙarfe da aka fallasa daga iskar oxygen da kuma samar da wani wuri mai solder. Zaɓuɓɓuka sun haɗa da daidaitawar iska mai zafi (HASL), zinare mai nickel immersion maras amfani da wutar lantarki (ENIG), ko sauran abubuwan ci gaba.

12. Roting da Forming: Ana yanke sassan PCB cikin allunan guda ɗaya ta amfani da na'ura mai ɗaukar hoto ko tsarin rubutun V.

Tabbatar cewa gefuna suna da tsabta kuma girman su daidai ne.

13. Gwajin Wutar Lantarki: Yi gwajin lantarki kamar gwajin ci gaba, ma'aunin juriya, da keɓancewa don tabbatar da aiki da amincin allunan ƙirƙira.

14. Ingancin Kulawa da Kulawa: Ana bincika allunan da aka gama da su sosai don kowane lahani na masana'anta kamar guntun wando, buɗewa, rashin daidaituwa, ko lahani na ƙasa. Aiwatar da matakan sarrafa inganci don tabbatar da bin ka'idoji da ƙa'idodi.

15. Packing da Shipping: Bayan hukumar ta wuce ingancin dubawa, an cika shi amintacce don hana lalacewa yayin jigilar kaya.

Tabbatar da ingantaccen lakabi da takaddun shaida don bin diddigin daidai da gano alluna.