PCB masu sassaucin ra'ayi 3 HDI don Lantarki na Mabukaci

Ƙayyadaddun bayanai

| Kashi | Iyawar Tsari | Kashi | Iyawar Tsari |

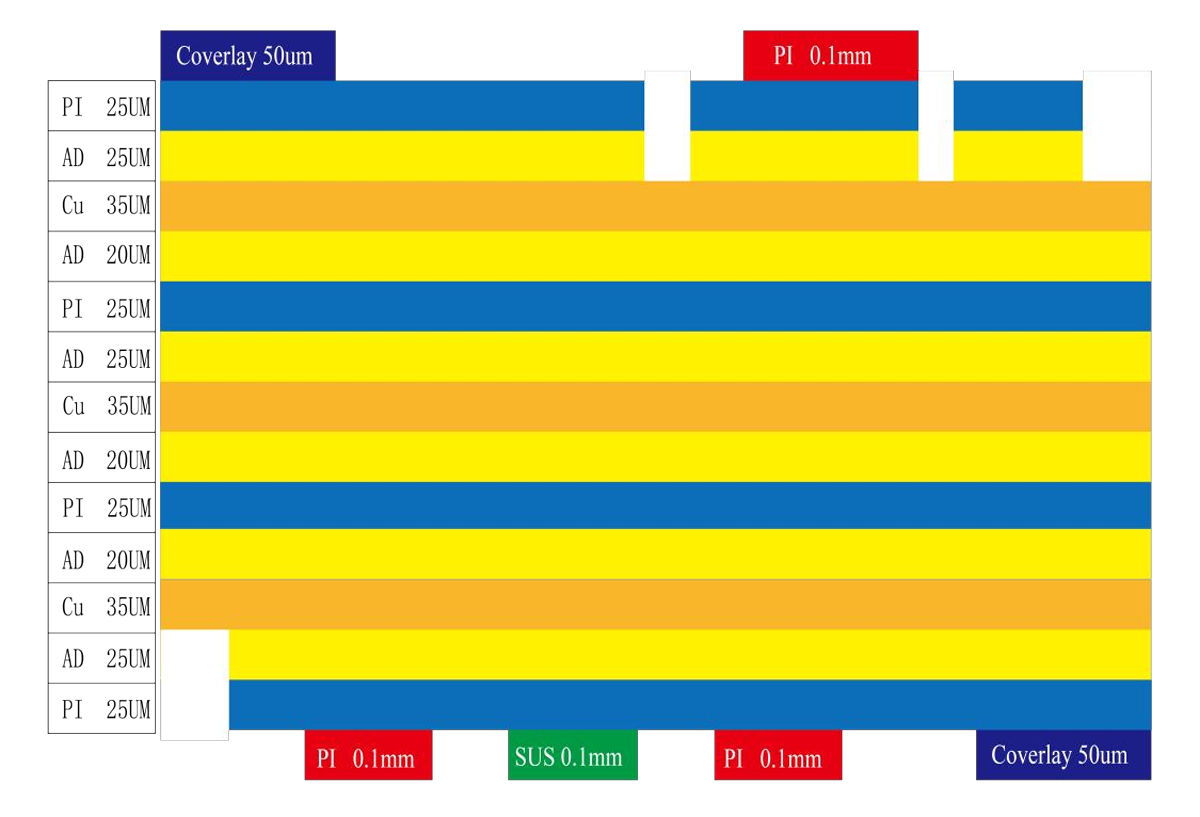

| Nau'in samarwa | FPC guda ɗaya / Layer Layer FPC Multi-Layer FPC / Aluminum PCBs Rigid-Flex PCB | Lambar Layer | 1-16 yadudduka FPC 2-16 yadudduka Rigid-FlexPCB HDI Alloli |

| Matsakaicin Girman Masana'anta | Single Layer FPC 4000mm Doulbe Layer FPC 1200mm Multi-Layer FPC 750mm M-Flex PCB 750mm | Insulating Layer Kauri | 27.5um / 37.5/ 50um / 65/ 75um / 100um / 125um / 150um |

| Kaurin allo | FPC 0.06mm - 0.4mm M-Flex PCB 0.25 - 6.0mm | Haƙuri na PTH Girman | ± 0.075mm |

| Ƙarshen Sama | Immersion Zinariya/ nutsewa Silver/Gold Plating/Tin Plat ing/OSP | Stiffener | FR4 / PI / PET / SUS / PSA / Alu |

| Girman Orifice Semicircle | Min 0.4mm | Min Line Space/ Nisa | 0.045mm/0.045mm |

| Hakuri mai kauri | ± 0.03mm | Impedance | 50Ω-120Ω |

| Kauri Na Karfe Copper | 9um/12um/18um/35um/70um/100um | Impedance Sarrafa Hakuri | ± 10% |

| Haƙuri na NPTH Girman | ± 0.05mm | Nisa Min Flush | 0.80mm |

| Min Via Hole | 0.1mm | Aiwatar da Daidaitawa | GB / IPC-650 / IPC-6012 / IPC-6013II / Saukewa: IPC-6013I |

Muna yin PCBs masu sassauƙa tare da ƙwarewar shekaru 15 tare da ƙwarewar mu

Gwaji da Kayan Aiki

Gwajin Microscope

Binciken AOI

Gwajin 2D

Gwajin Tashin hankali

Gwajin RoHS

Binciken Flying

Gwaji na kwance

Lankwasawa Teste

Sabis na PCBs ɗin mu na Flex

.Ba da goyon bayan fasaha kafin sayarwa da bayan-sayarwa

Sulotion-Daya Tsaya, 1-2days Saurin juyo abin dogaro abin dogaro.

.Caters zuwa duka Medical Na'urar, Industrial Control, Automotive, Aviation, IOT, UAV, Communications da dai sauransu.

.Ƙungiyoyin injiniyoyinmu da masu bincike sun sadaukar da kansu don cika bukatunku tare da daidaito da ƙwarewa.

Flex PCBs FAQ

1. Menene ra'ayoyin ƙira don PCBs masu sassauci?

Lokacin zayyana PCBs masu sassauƙa, yana da mahimmanci a yi la'akari da abubuwa kamar radius lanƙwasa, adadin yadudduka da ake buƙata, da kowane ƙuntatawar lantarki. Har ila yau, yana da mahimmanci don zaɓar madaidaicin maɗaukaki da manne don tabbatar da sassaucin da ake so da karko.

2. Menene nau'ikan PCBs masu sassauci?

Akwai nau'ikan PCB masu sassauƙa da yawa waɗanda zasu iya biyan buƙatun ƙira daban-daban, gami da:

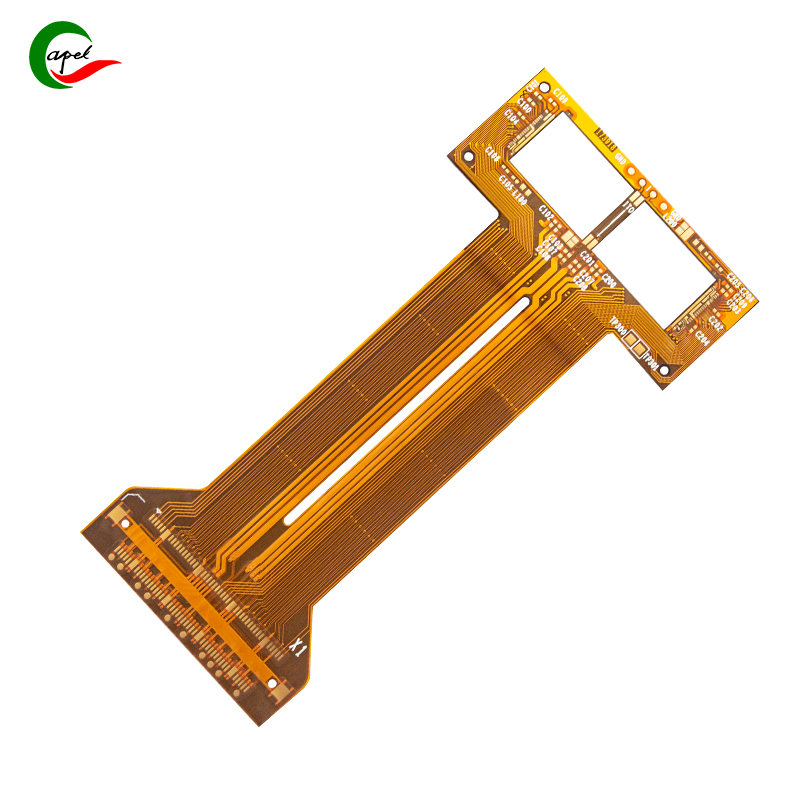

- PCBs masu sassauƙa mai gefe guda: Hanyoyi masu aiki a gefe ɗaya da substrate a ɗayan.

- PCBs masu sassauƙa mai gefe biyu: Akwai alamun tafiyarwa a ɓangarorin biyu da maƙallan a tsakiya.

- Multilayer flex PCBs: yana da yadudduka da yawa na alamomin gudanarwa da kuma abin rufe fuska.

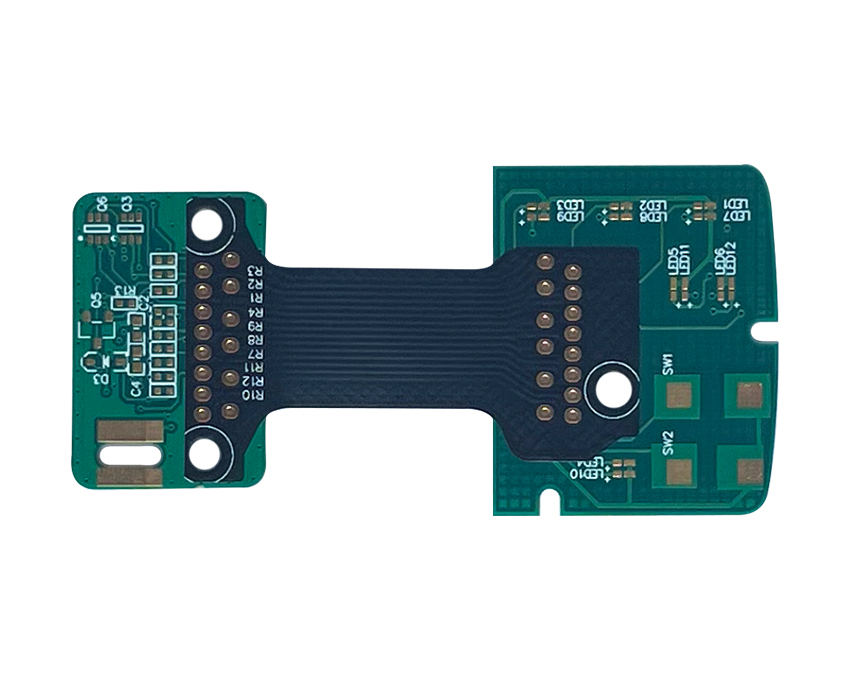

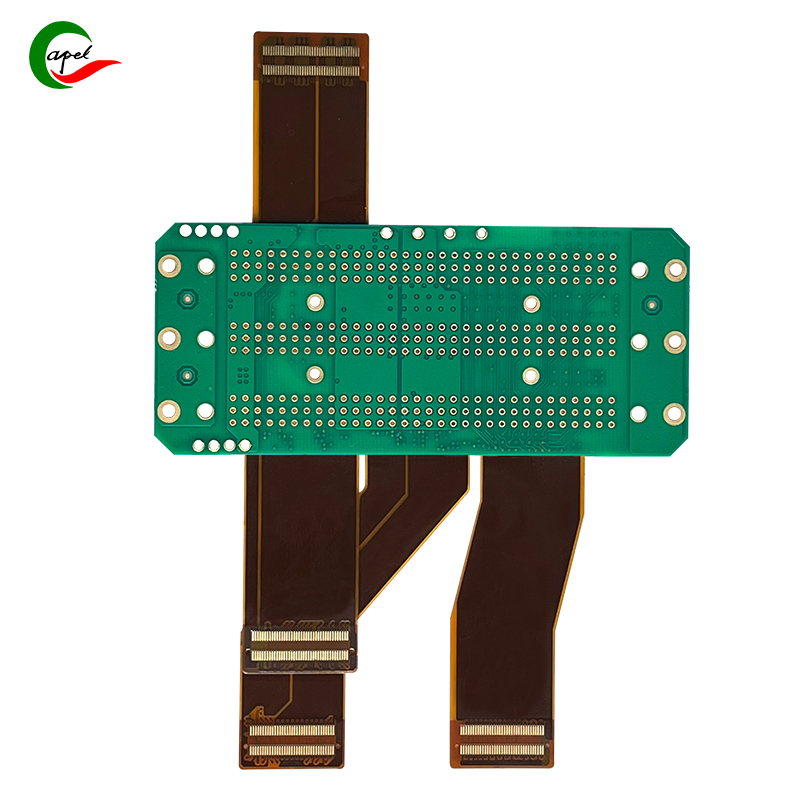

- PCBs mai ƙarfi-mai sassauci: Yana da alaƙa da haɗaɗɗun madaidaitan madauri da sassauƙa don samar da dorewa da sassauci.

3. Menene tsarin gwaji don PCBs masu sassauci?

Flex PCBs suna fuskantar gwaje-gwaje daban-daban a cikin tsarin masana'antu, gami da gwajin ci gaba na lantarki, gwajin zafi, da gwajin injina don tabbatar da sun cika ƙa'idodin da ake buƙata da ƙayyadaddun bayanai.

4. Za a iya gyara PCBs Flex?

Za'a iya gyara PCBs Flex a wasu lokuta, amma wannan ya dogara da girman lalacewa. Za'a iya gyara ƙaramar lahani ga lamurra ko tarkace, amma babbar lalacewa na iya buƙatar musanyawa.

5. Wadanne abubuwa ne ya kamata a yi la'akari da su lokacin zabar masana'anta PCBs masu sassauci?

Lokacin zabar mai ƙera PCBs, yana da mahimmanci a yi la'akari da ƙwarewar masana'anta, gwaninta da kuma suna. Hakanan ya kamata ku kimanta wuraren samar da su, kayan aiki, hanyoyin sarrafa inganci, da sabis na tallafin abokin ciniki. Hakanan, yana da mahimmanci don tabbatar da cewa masana'anta na iya biyan takamaiman buƙatun ƙira da jadawalin bayarwa.